Flow Meter

- Home

- Flow Meter

Flow Meter Manufacturer

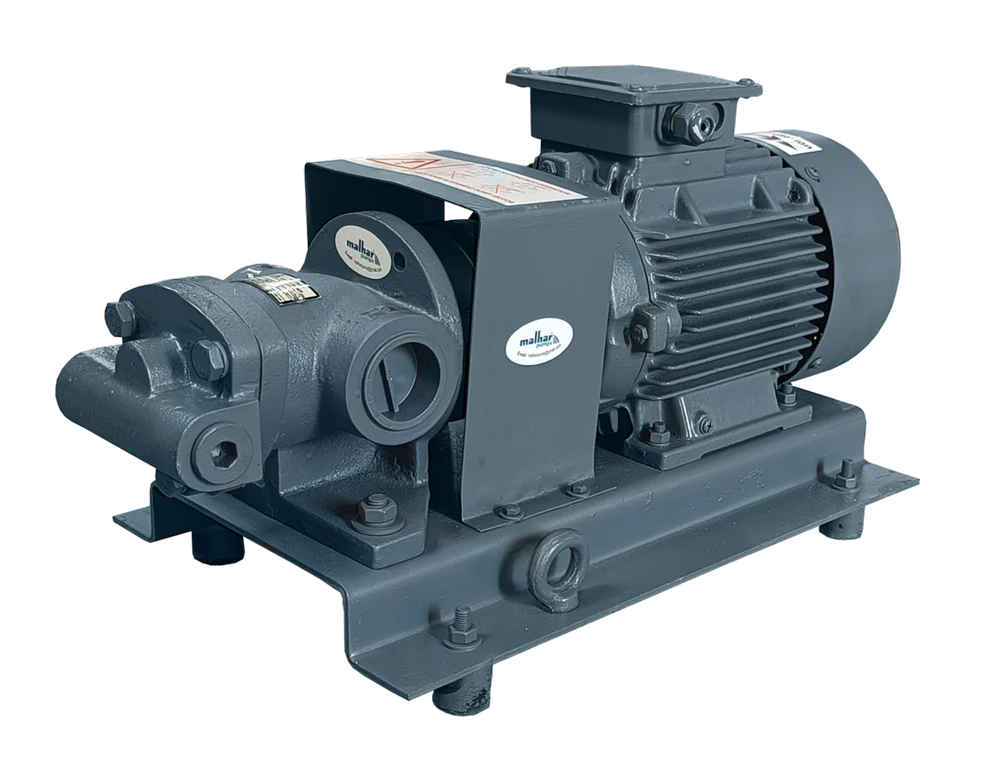

Are you looking for flow meter manufacturer in India? Creative Engineers is your trusted partner, specializing in high-quality flow meters for industries such as water management, oil, gas, and chemical processing, where precision, durability, and efficiency are essential. With over 25 years of expertise, we offer ISO-9001:2008 certified electromagnetic digital flow meters, ensuring superior performance and reliability.

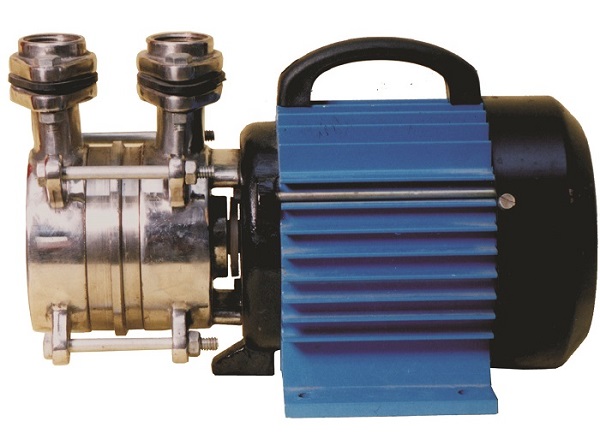

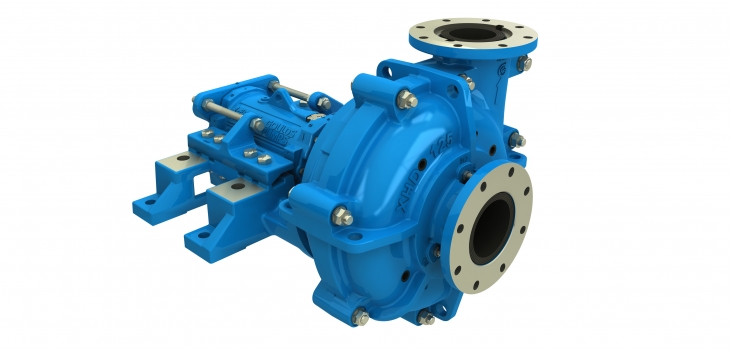

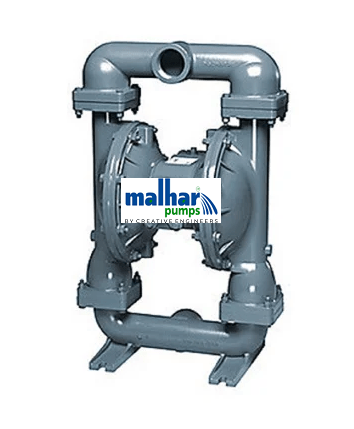

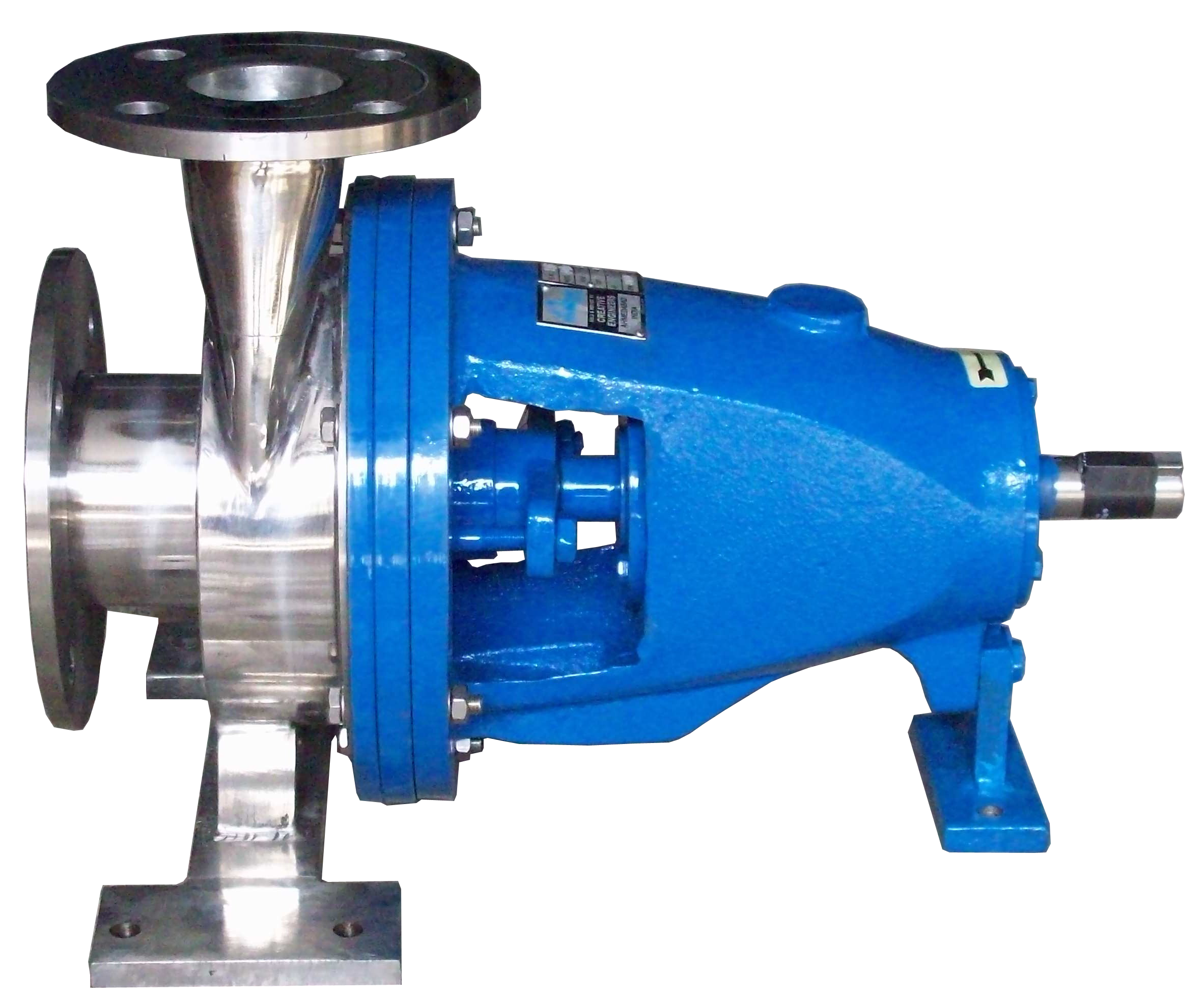

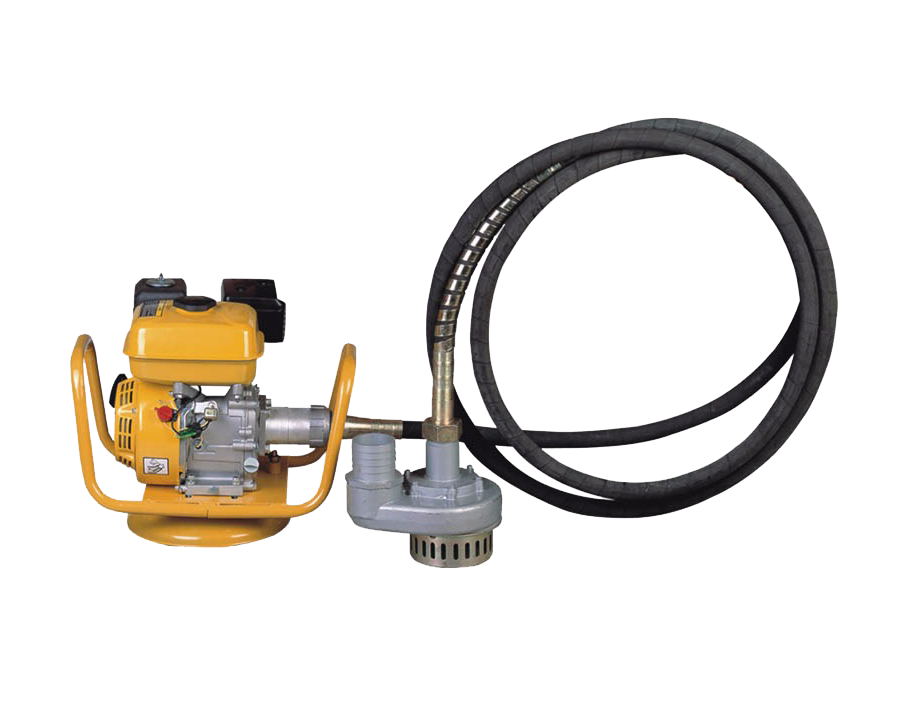

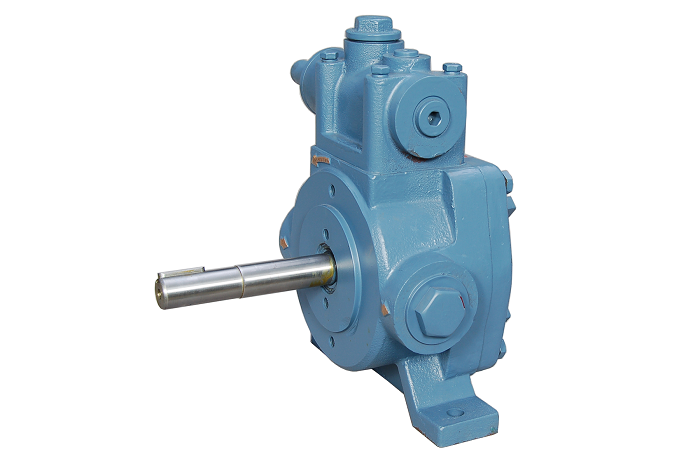

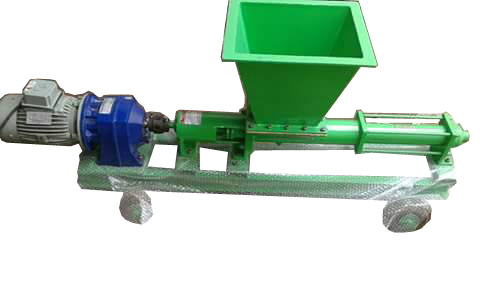

Our diverse range of flow meters includes fuel transfer products, ultrasonic flow meters, pressure differential meters, electromagnetic flow meters (full bore type), gas turbine flow meters, mass flow meters, and vortex flow meters. Flow meters are critical instruments for measuring the flow rate or volume of liquids and gases in pipelines. They operate using various principles, such as fluid velocity, pressure detection, and displacement measurement. Ultrasonic flow meters determine flow rates by analyzing sound wave speed, while gas turbine flow meters measure flow based on rotor speed proportional to fluid movement. Other types, including mechanical, electromagnetic, and pressure differential meters, cater to specific industrial applications.

Frequently Asked Questions

A flow meter is a device used to measure the flow rate of liquids, gases, or steam in industries. It helps monitor and control fluid movement for efficient operations.

A flow meter operates by detecting the velocity, pressure, or displacement of a fluid passing through a system. Different types of flow meters use various mechanisms, such as mechanical, electromagnetic, ultrasonic, and thermal technologies, to provide accurate measurements.

Flow meters are widely used in industries such as water treatment, oil and gas, pharmaceuticals, food and beverage, HVAC systems, and chemical processing. They help in measuring and controlling fluid movement to ensure efficiency and compliance with regulations.

Flow meters enhance process efficiency, reduce waste, improve product quality, and help in energy conservation. They provide real-time monitoring, allowing for better control and decision-making in fluid management systems.