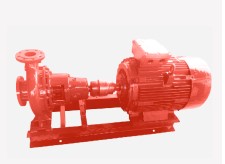

SS Centrifugal Pump

- Home

- SS Centrifugal Pump

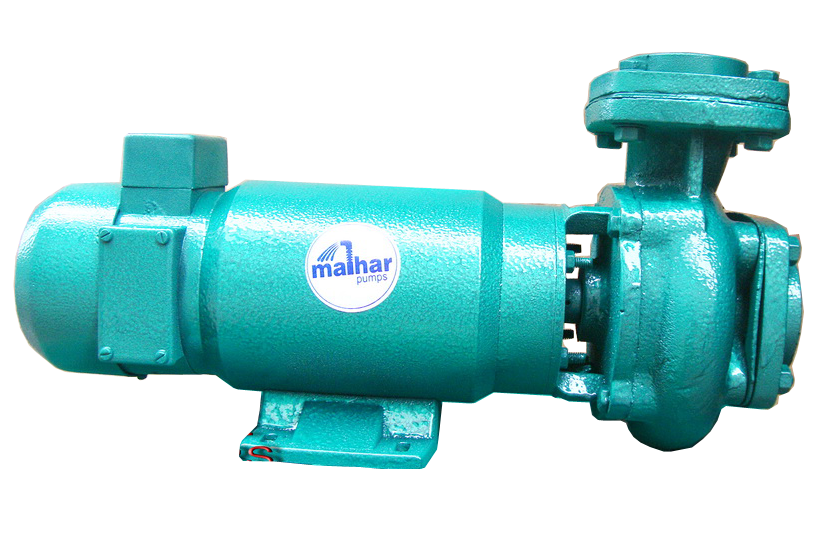

SS Centrifugal Pump Manufacturer

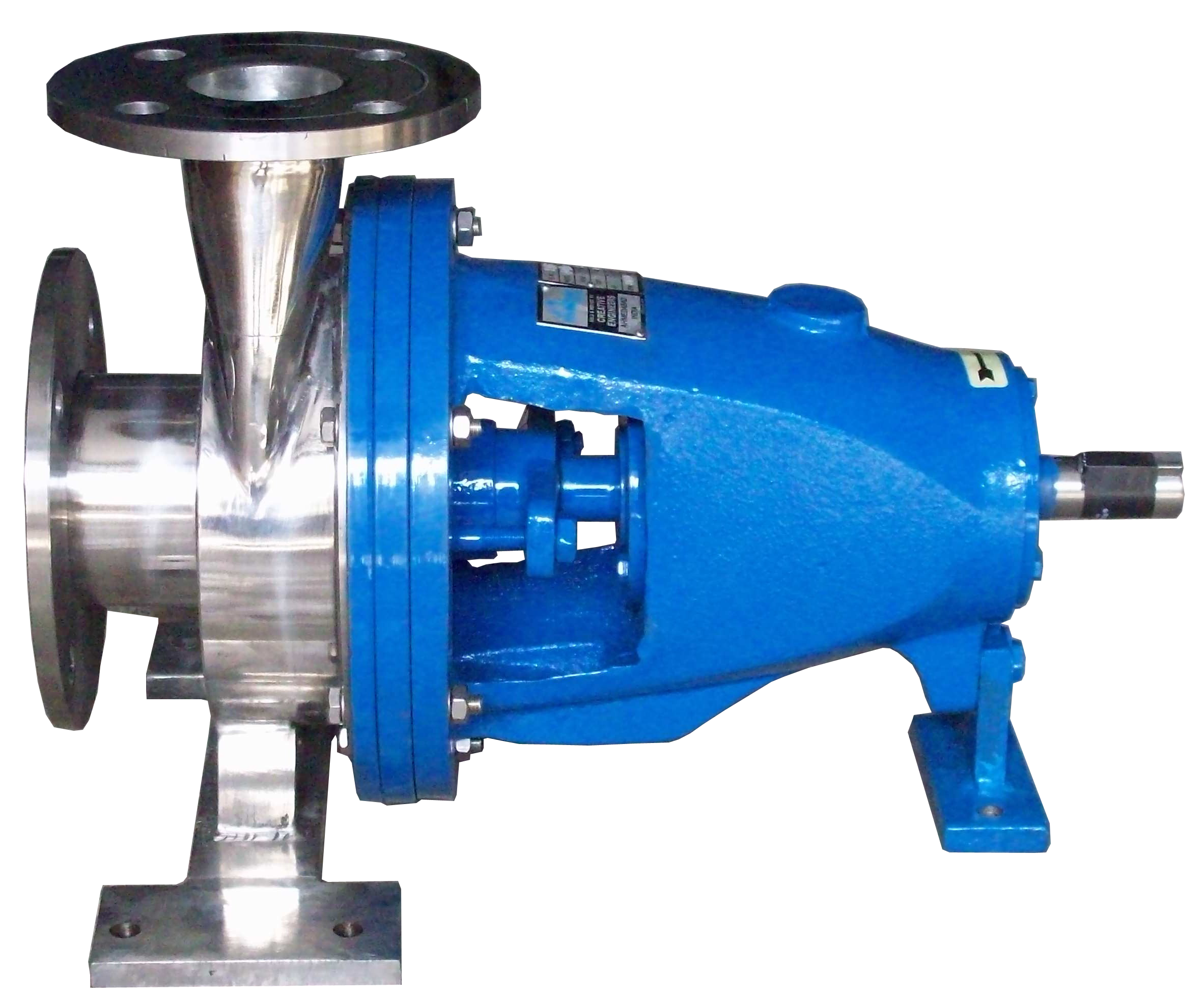

Gen Creative Engineers Limited is one of the leading SS Centrifugal Pump Manufacturer, Supplier, and Exporter in India with 25 years of industry expertise. An SS Centrifugal Pump is a high-performance, corrosion-resistant pump designed for efficient fluid transfer in demanding industrial applications. Made from stainless steel, it ensures durability, reliability, and resistance to aggressive chemicals, making it use for industries such as chemical processing, pharmaceuticals, and food production.

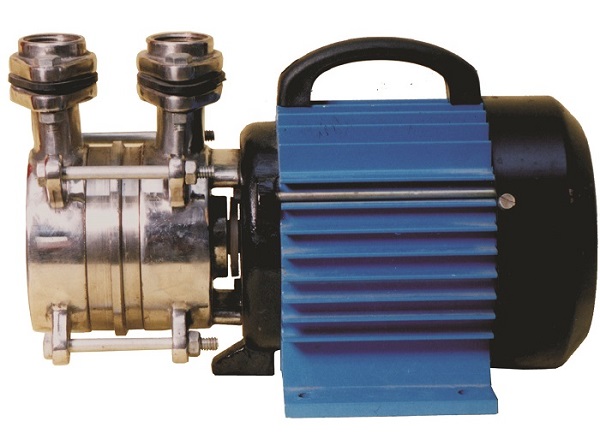

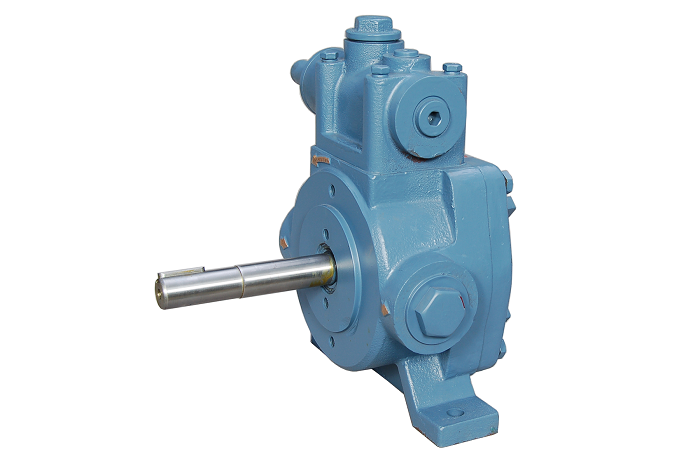

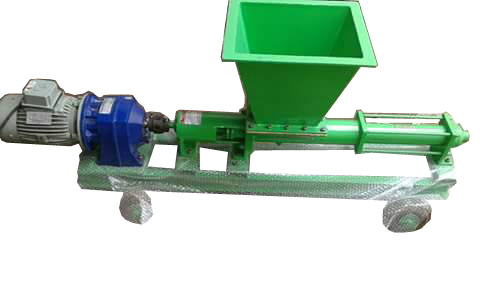

- CF Series Stainless Steel Centrifugal Pumps: Designed for efficient fluid transfer with high durability and optimal performance.

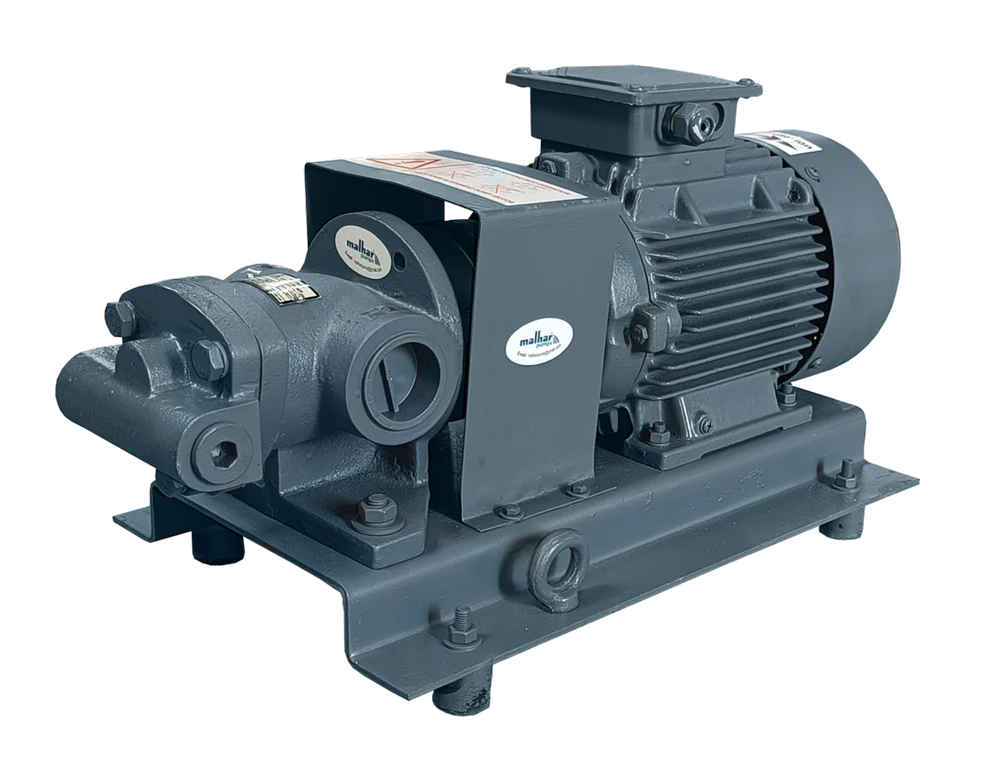

- CFS Series Stainless Steel Centrifugal Pumps: Engineered for smooth operation, offering corrosion resistance and reliable functionality.

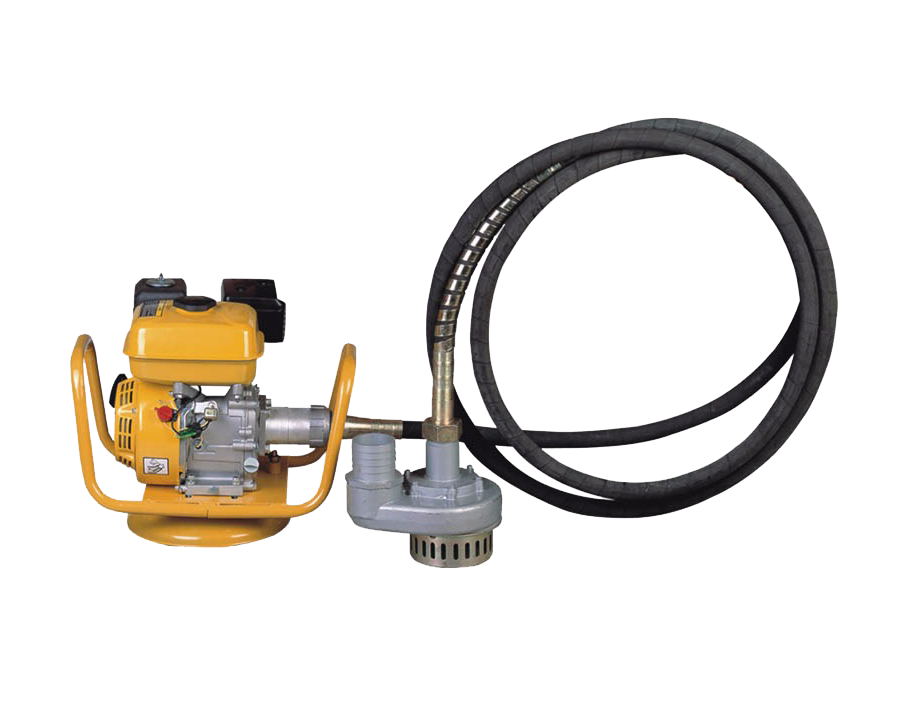

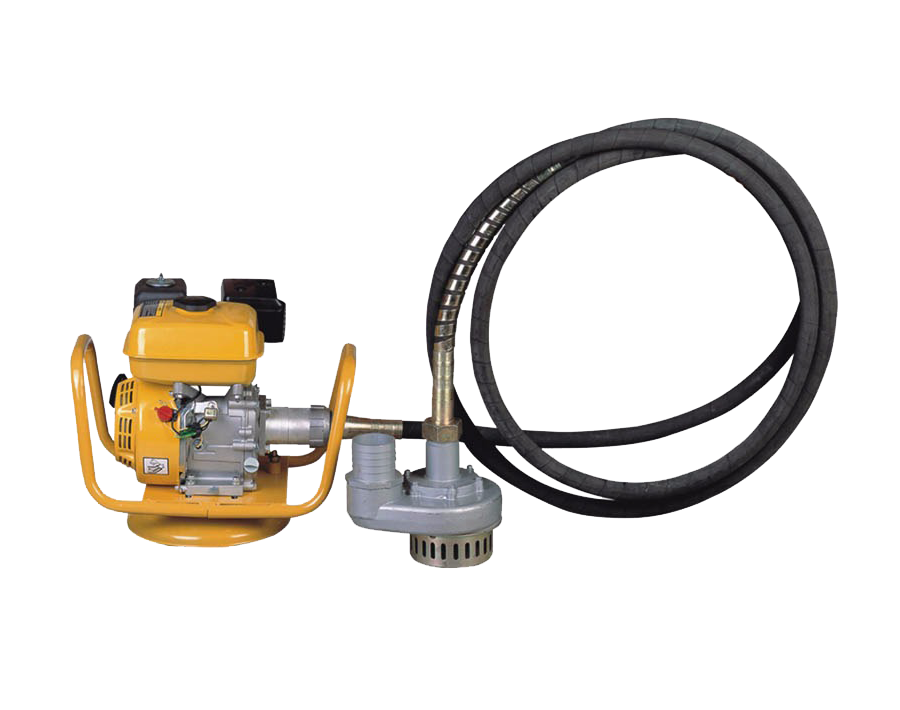

- Self-Priming Pumps: use for applications requiring quick startup, ensuring consistent and hassle-free performance.

What is SS Centrifugal Pump?

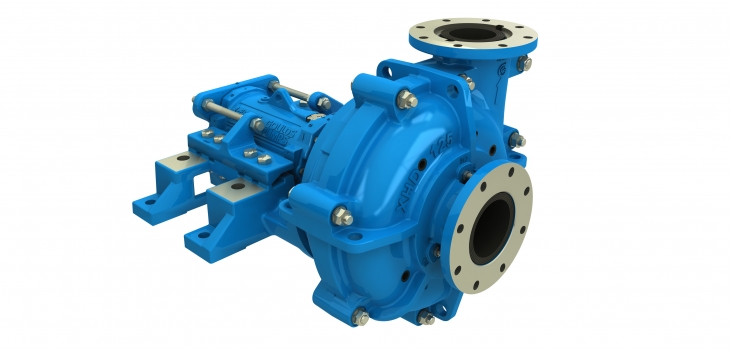

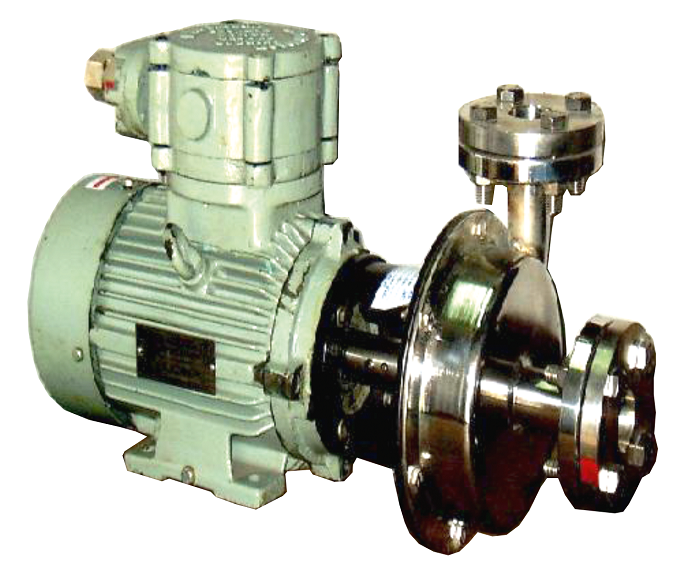

An SS centrifugal pump is a centrifugal pump made from stainless steel (SS), designed for applications involving corrosive or aggressive fluids. Due to its high resistance to corrosion and chemical attack, it ensures durability and efficiency in demanding environments.

How It Works

SS centrifugal pumps operate using a rotating impeller that generates a low-pressure zone at the center, drawing fluid into the pump through the inlet. As the impeller spins, the fluid is forced outward, creating a high-pressure zone that pushes the fluid out through the outlet, enabling smooth and continuous fluid transfer.

SS Centrifugal Pump Features & Applications

- Durable & Corrosion-Resistant: Stainless steel construction ensures superior longevity in challenging conditions.

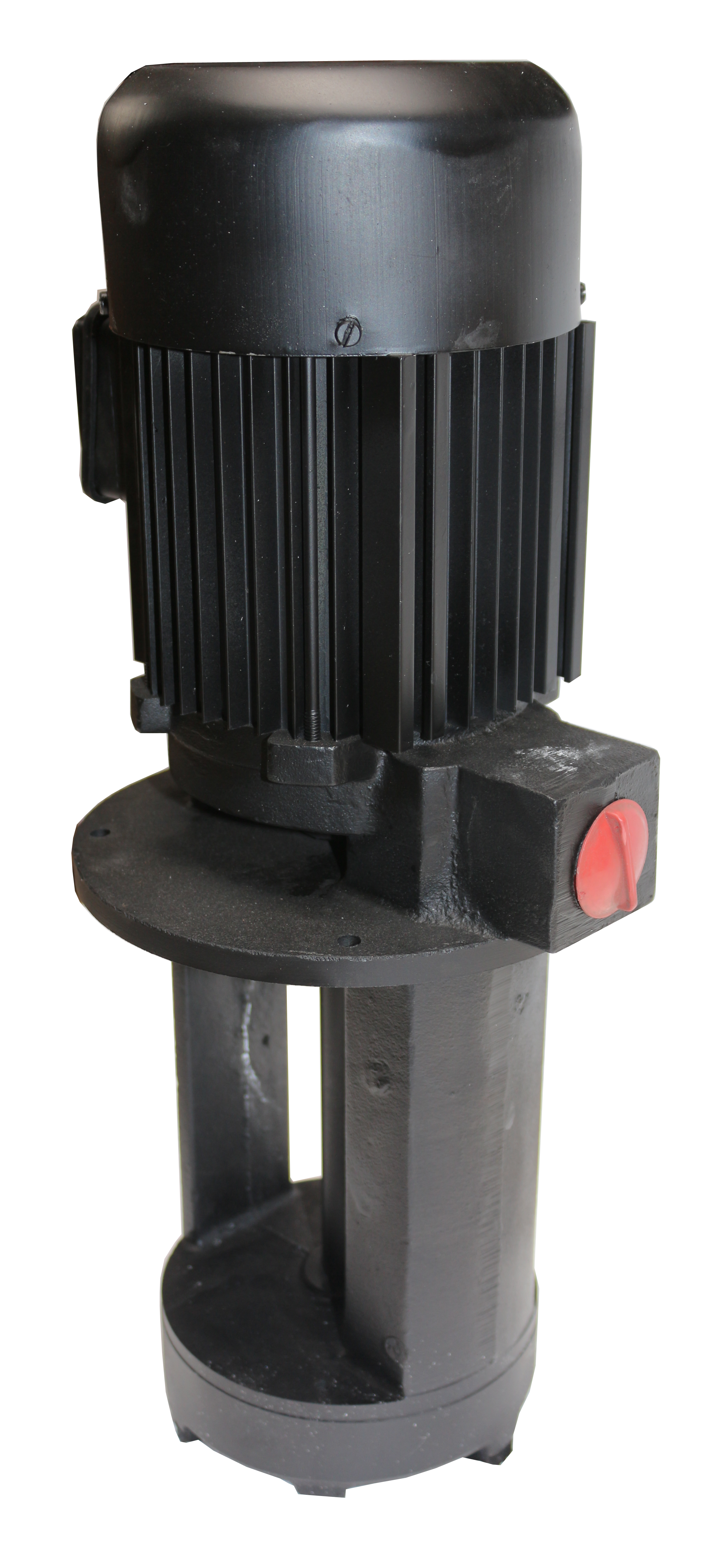

- Versatile Designs: Available in sizes and configurations to suit different industrial needs.

- Efficient Fluid Handling: Designed for optimal performance across diverse operating conditions.

- Industry Applications: Widely used in chemical processing, pharmaceuticals, and food & beverage production.

Frequently Asked Questions

An SS centrifugal pump is a stainless steel pump designed to move fluids using centrifugal force. It is known for its corrosion resistance, durability, and suitability for hygienic applications.

They are widely used in industries such as food and beverage, pharmaceuticals, dairy, chemical processing, and water treatment due to their hygienic properties and resistance to aggressive fluids.

Regular maintenance includes checking for wear, cleaning the impeller and casing, inspecting seals and bearings, and ensuring there is no clogging or leakage to maintain optimal performance.

Yes, when properly sized and maintained, stainless steel centrifugal pumps offer high efficiency and low operating costs over time, especially in continuous-use applications.

Regular inspection, seal checks, lubrication, and timely replacement of worn components help maintain performance and extend the lifespan of the pump.