Mud Pump

- Home

- Mud Pump

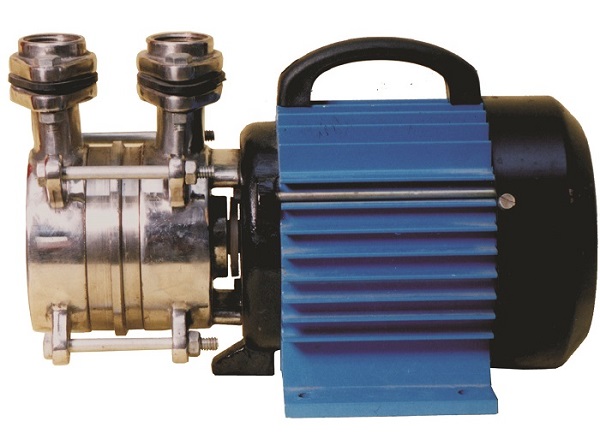

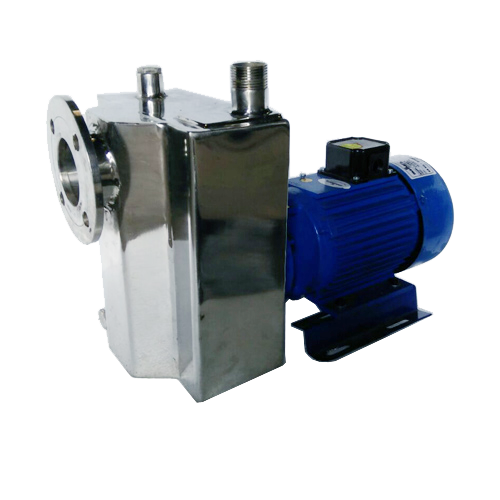

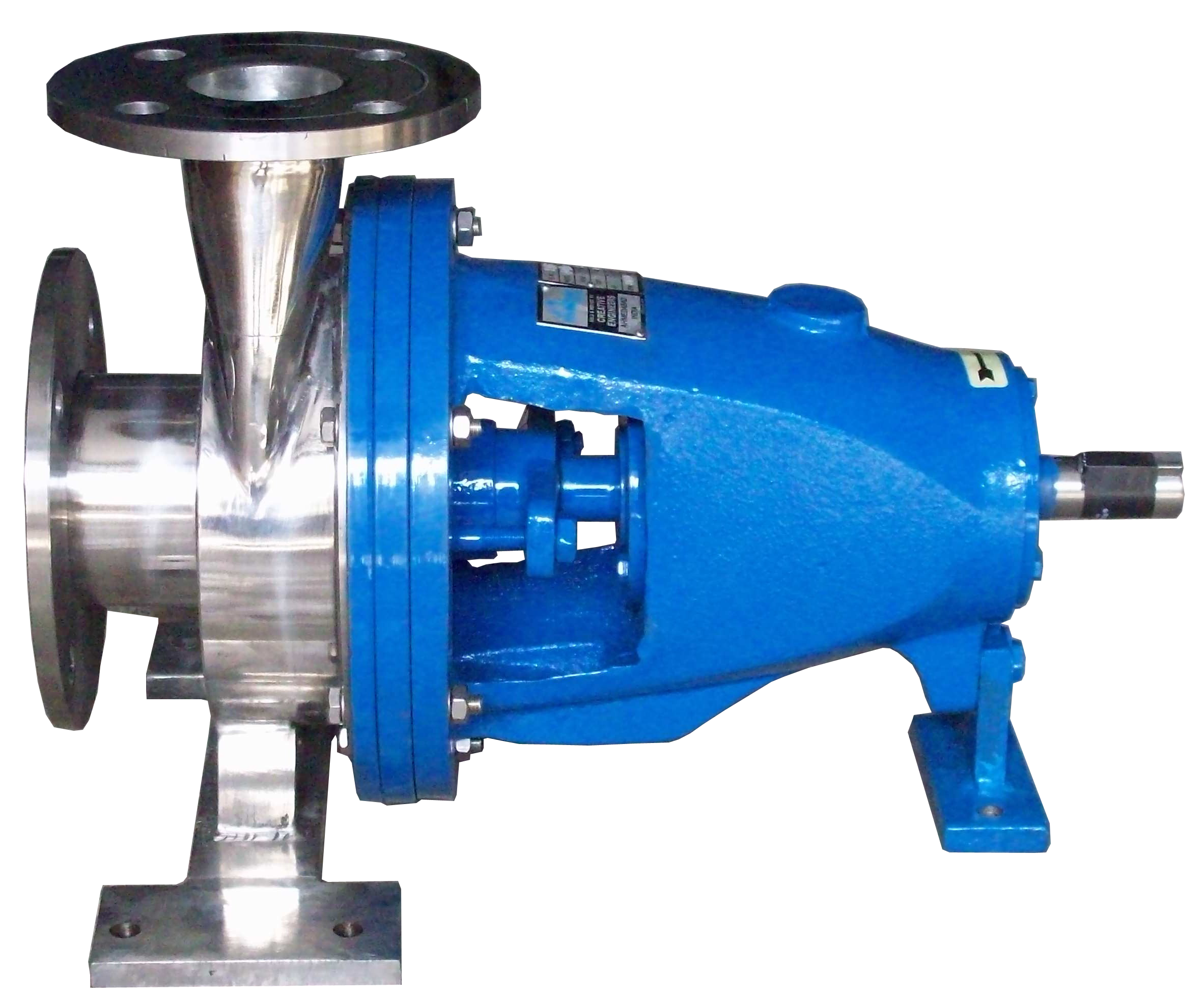

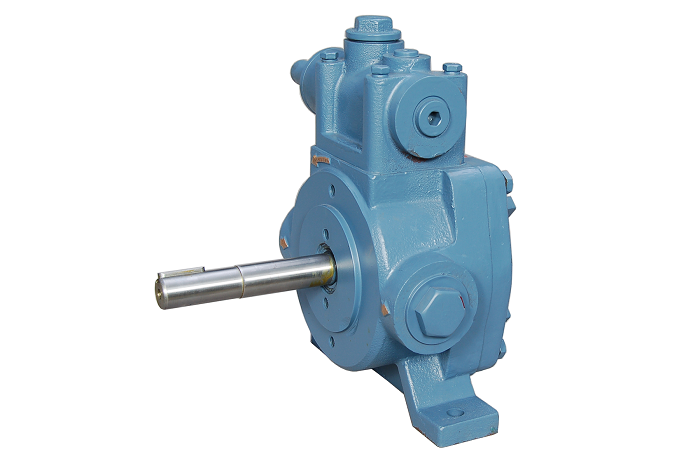

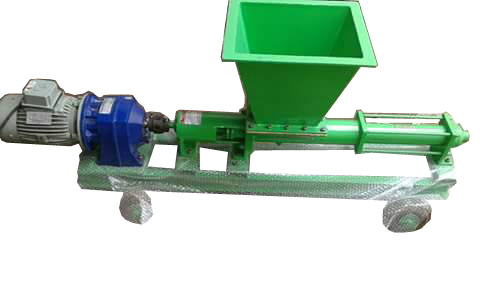

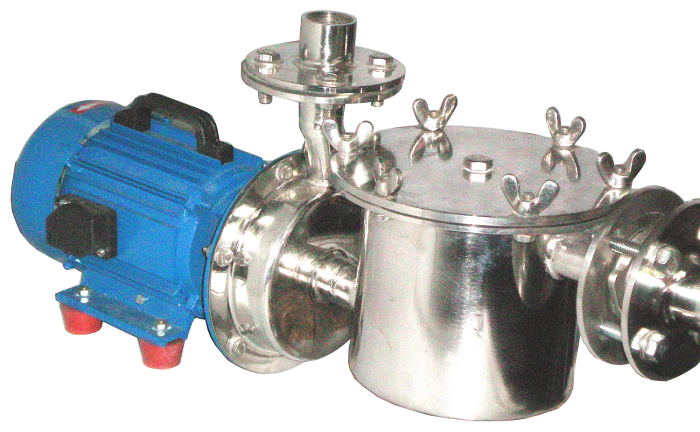

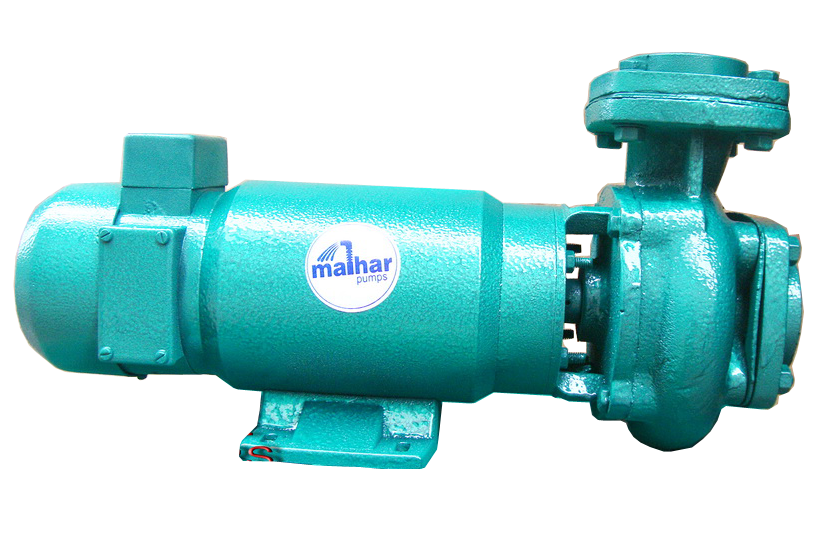

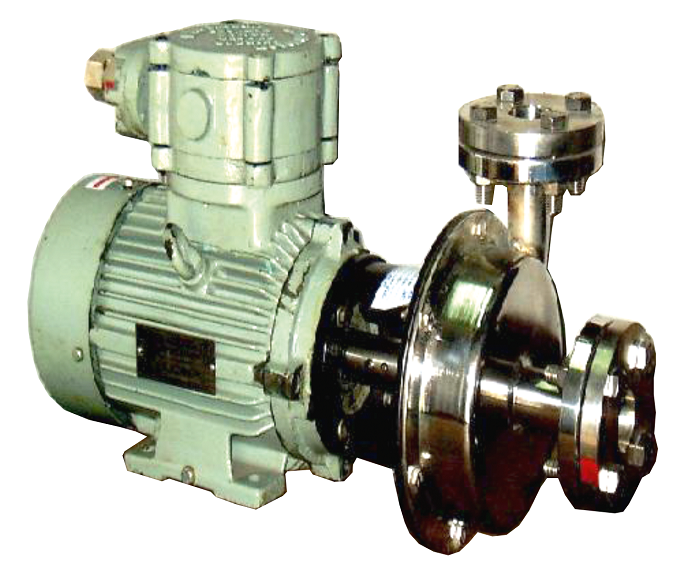

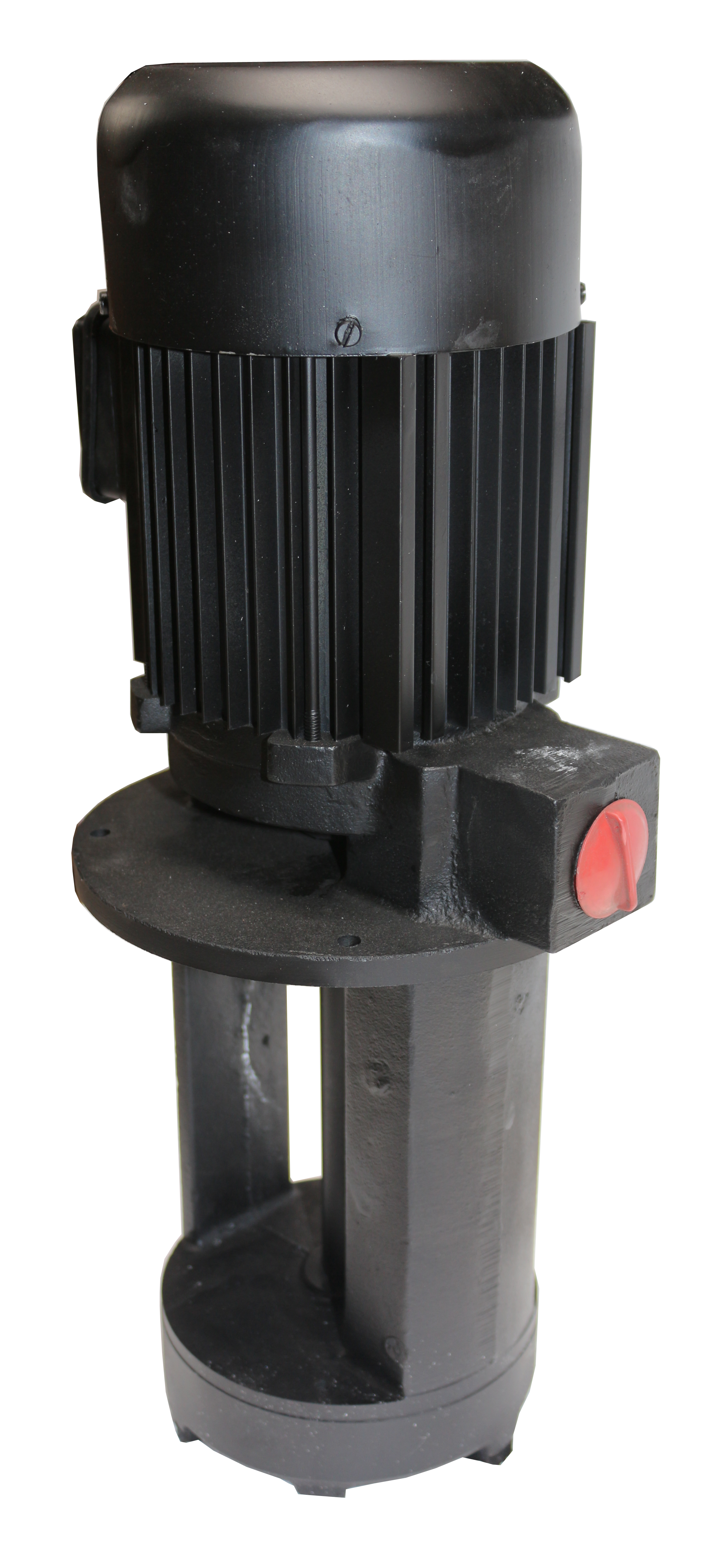

Mud Pump Manufacturer

We provide a qualitative range of Mud Pumps, which are immensely used in construction, agriculture, waste water management and many other industries. These Mud Pumps are primarily reciprocating plunger devices designed for circulation of drilling fluid down the drill string and back up the annulus. Our range of pumps are suitable for pumping muddy water, sewage, polluted liquids & solids and also in swimming pool. Manufactured using latest technology, these pumps are high performing, abrasion resistant, easy to install and have long service life.

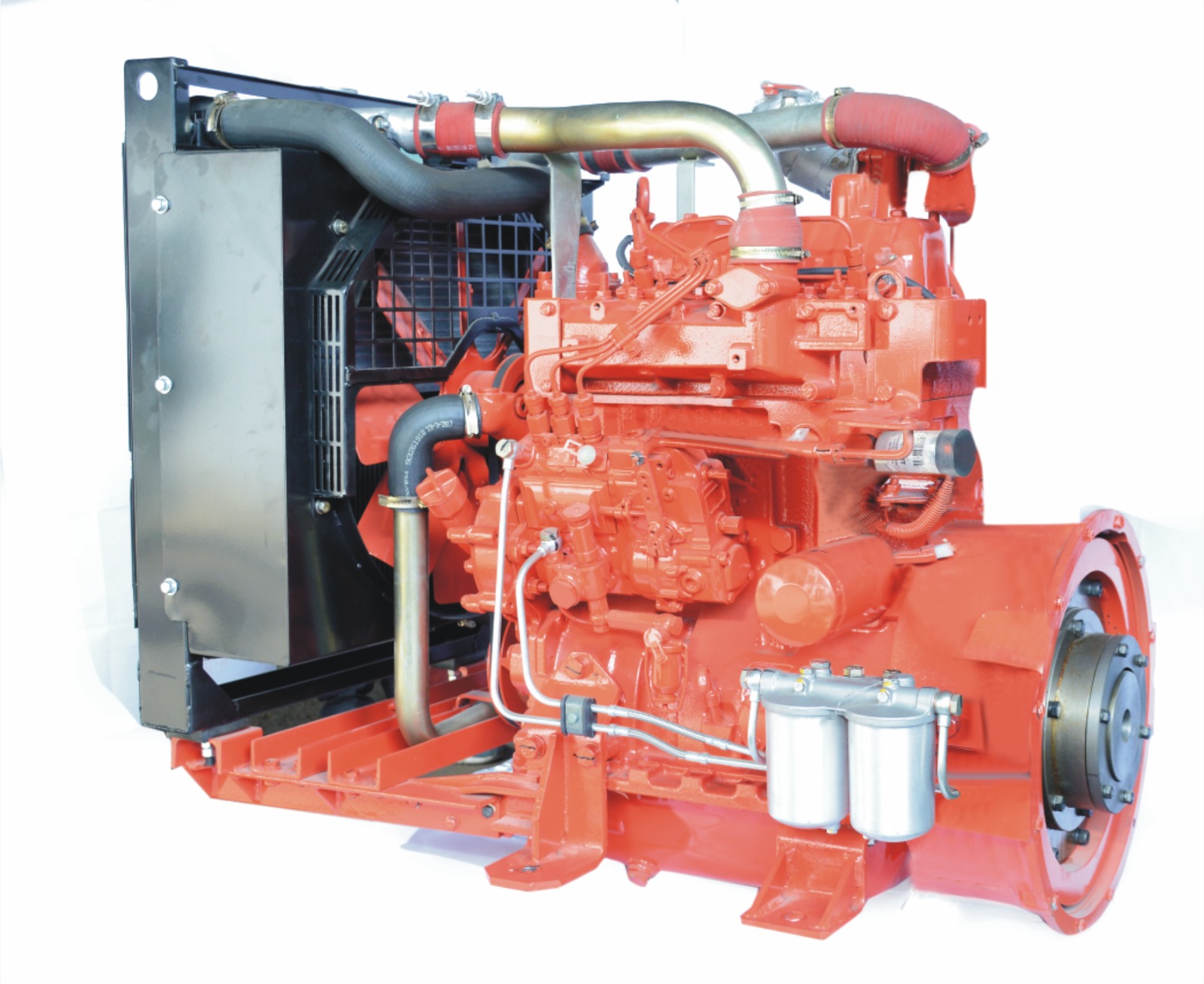

Mud Pump Manufacturer

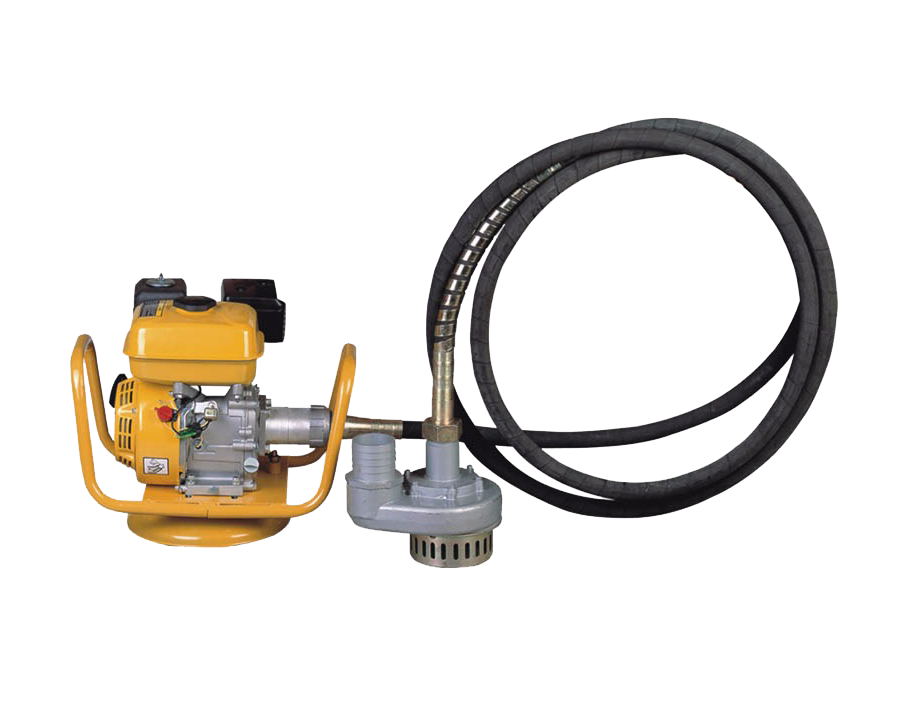

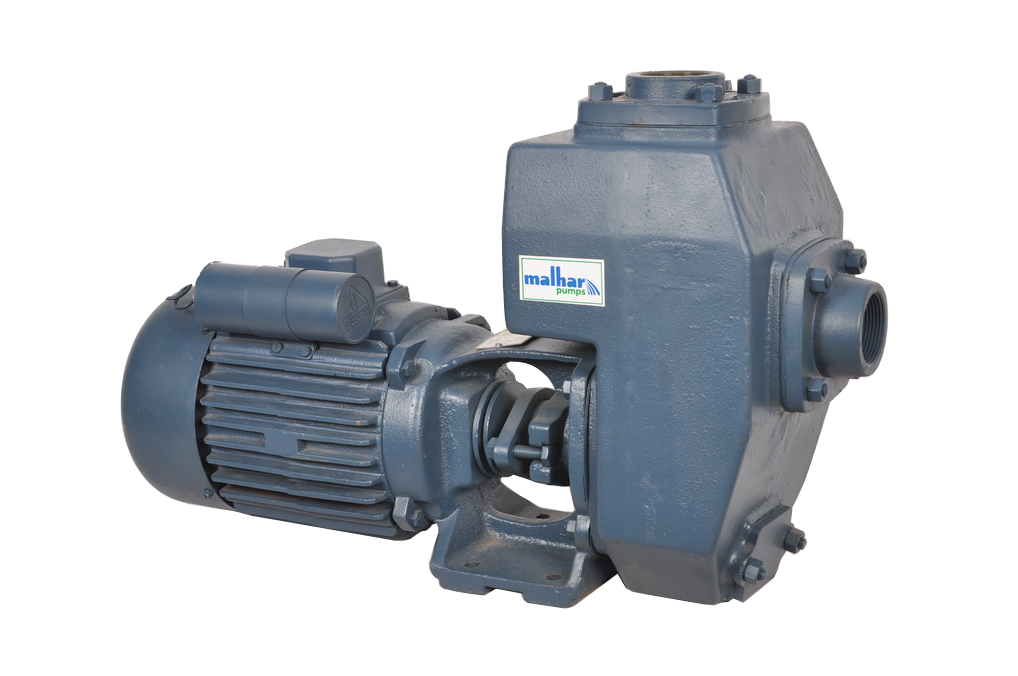

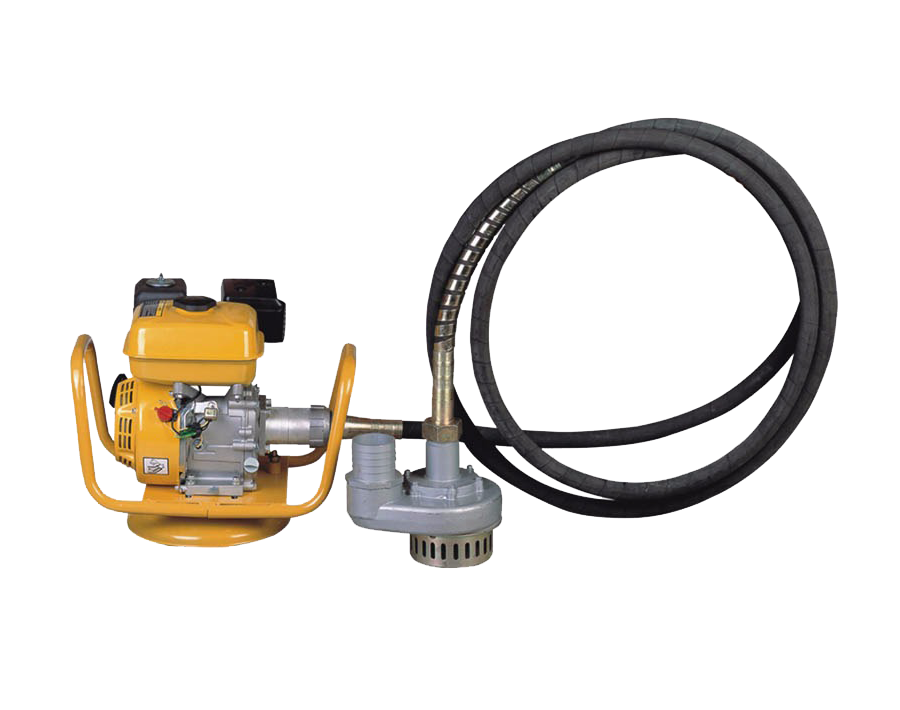

Are you looking for mud pump manufacturer in India? Creative Engineers is the perfect choice for you. We specialize in high-quality industrial mud pump, engine- driven mud pump, mud monoblock pump engineered for efficient performance in construction, mining, and oil & gas industries. Our pumps are designed with durability in mind, delivering exceptional high-pressure and fluid handling capabilities essential for rigorous operations.

As an ISO-9001:2008 certified mud pump manufacturer, supplier and exporter in India, we have been delivering innovative pumping solutions for over 25 years. Our high-performance mud pumps are engineered for precision, durability, and maximum efficiency, ensuring reliable operation across industries. With cutting-edge technology and decades of expertise, we provide solutions that enhance productivity and operational excellence.

Mud Pump Features:

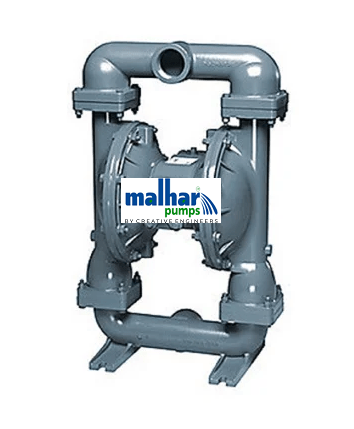

- Excellent quick automatic priming action without foot valve up to 8 mtrs.

Automatic air release during priming. - Back pull out design, so easy maintenance without disturbing pipe lines.

- Dynamically balanced rotating parts ensure less vibrations.

- Better efficiency because of good hydraulic design.

- Minimum parts, fast repairing at low cost, Also pump is available at economical rate, Available in Bare, Coupled, Monobloc, Belt driven & Engine driven version.

- Also offered pump with trolley / trailer to move it from one place to another, Monobloc pumps can be able to with stand with wide voltage fluctuations, Pumps can be fitted with mechanical seal as per customer's requirements Less expensive & easily available spares.

- Very simple construction, only two moving parts Easy inspection of impeller.

Mud Pump Applications:

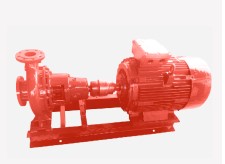

- Public utilities : For pumping muddy water, sewage, polluted liquids, solid and in swimming pool. Dewatering Basements, Trenches, Construction sites Onboard shift, as bilge pump, for desk wash & engine cooling. Tiles & Marble factories, effluent plants.

- Mobile Machinery : Cooling water for marine engines and shovels any application where priming is to be avoided.

- Industry : Transfer of clean 01 dirty neutral, acid or alkali liquids containing sand, mud or solids in suspension; clean or dirty low viscosity petroleum products or solvents; milk of lime, caustic soda; washing, cooling, circulation; smoke scrubbing; emergency duty.

Frequently Asked Questions

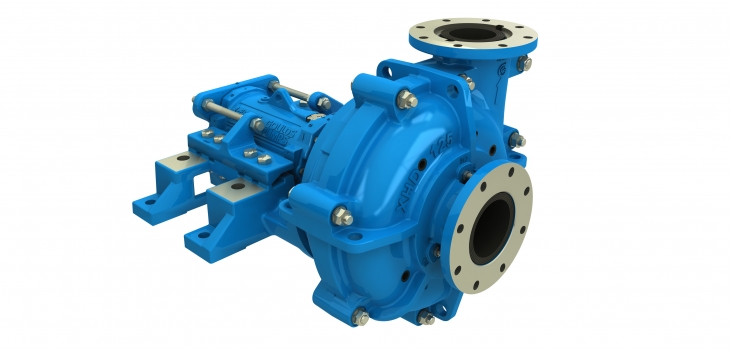

A mud pump is a reciprocating pump used in drilling operations to circulate drilling fluid (drilling mud) through the drill string and back to the surface.

A mud pump is a critical component in drilling operations, used to circulate drilling fluid (or "mud") down the drill string and back up the annulus to remove cuttings, cool the drill bit, and maintain pressure.

The two primary types are duplex (two-cylinder) and triplex (three-cylinder) pumps. Triplex pumps are more common in modern drilling due to their efficiency, smoother operation, and reduced pulsation.

Regular maintenance is essential to ensure reliable operation. Daily inspections, routine lubrication, and scheduled servicing of components like pistons, liners, and valves help prevent downtime and extend pump life.