Lobe Pump

- Home

- Lobe Pump

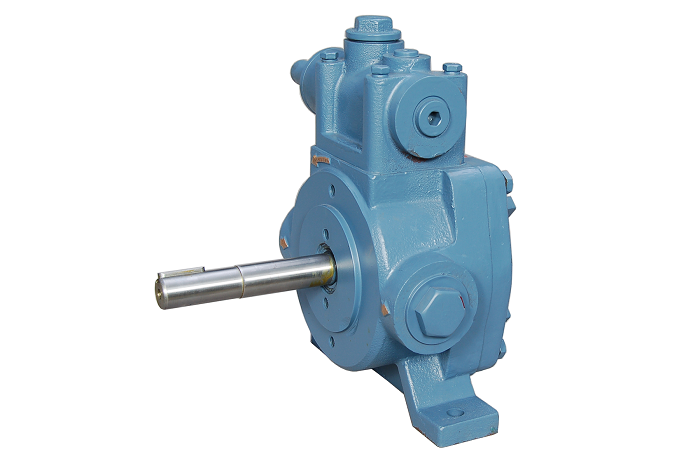

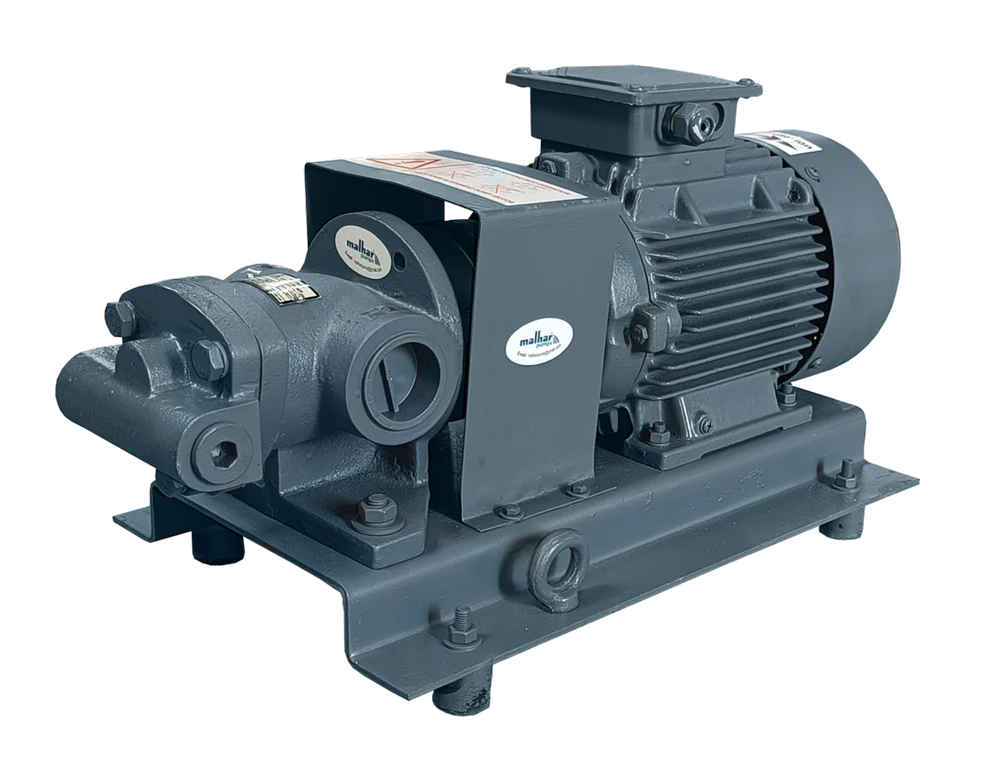

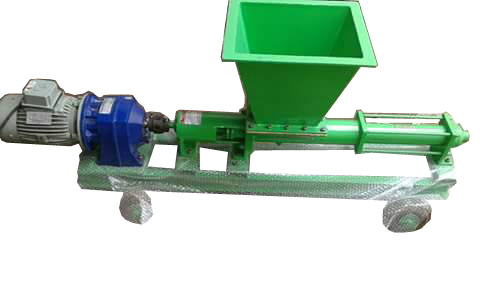

Lobe Pump Manufacturer

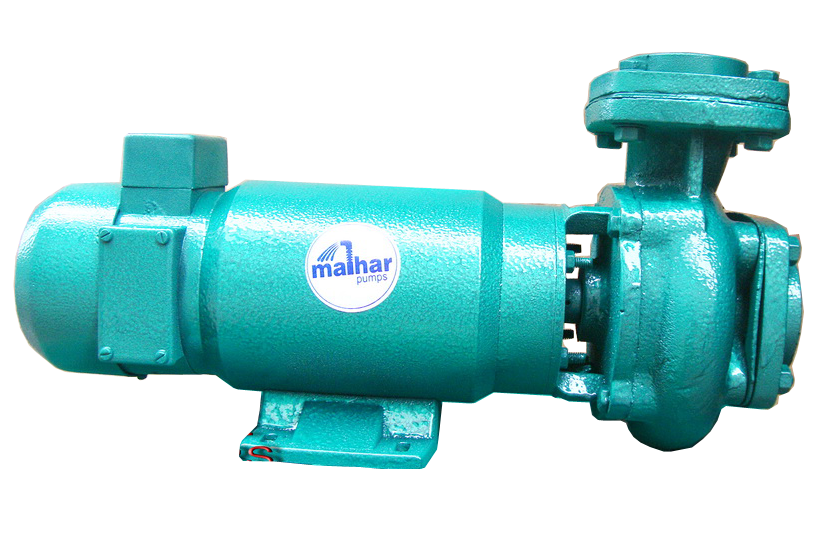

Creative Engineers is a leading Rotary Lobe Pump manufacturer, supplier, and exporter in India. Our high-performance lobe pumps are designed for smooth, hygienic, and efficient fluid transfer across industries like food, pharmaceuticals, and chemicals. Engineered for durability and reliability, our pumps have minimal maintenance and maximum efficiency. With precision engineering and superior quality, we provide customized solutions to meet diverse industrial needs.

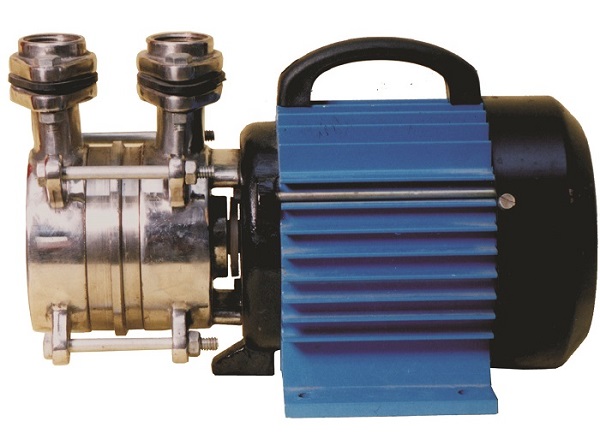

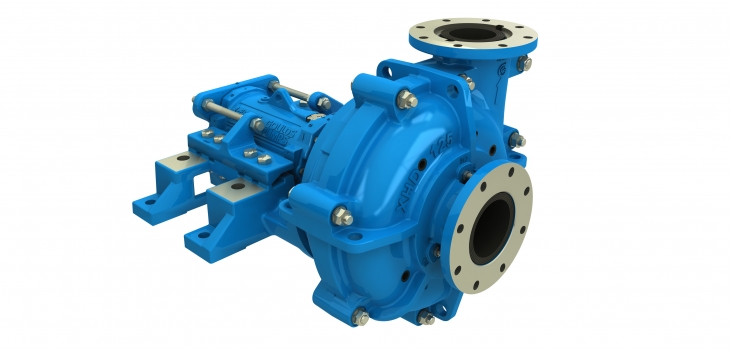

Lobe pump are available in different configurations, including rotary lobe pumps, twin-lobe pumps, and three-lobe pumps. They can handle a range of fluids, from low to high viscosity, and can transfer fluids with solids or particles without causing any damage to the fluid or the pump. They are known for their efficient and reliable performance, low noise levels, and easy maintenance.

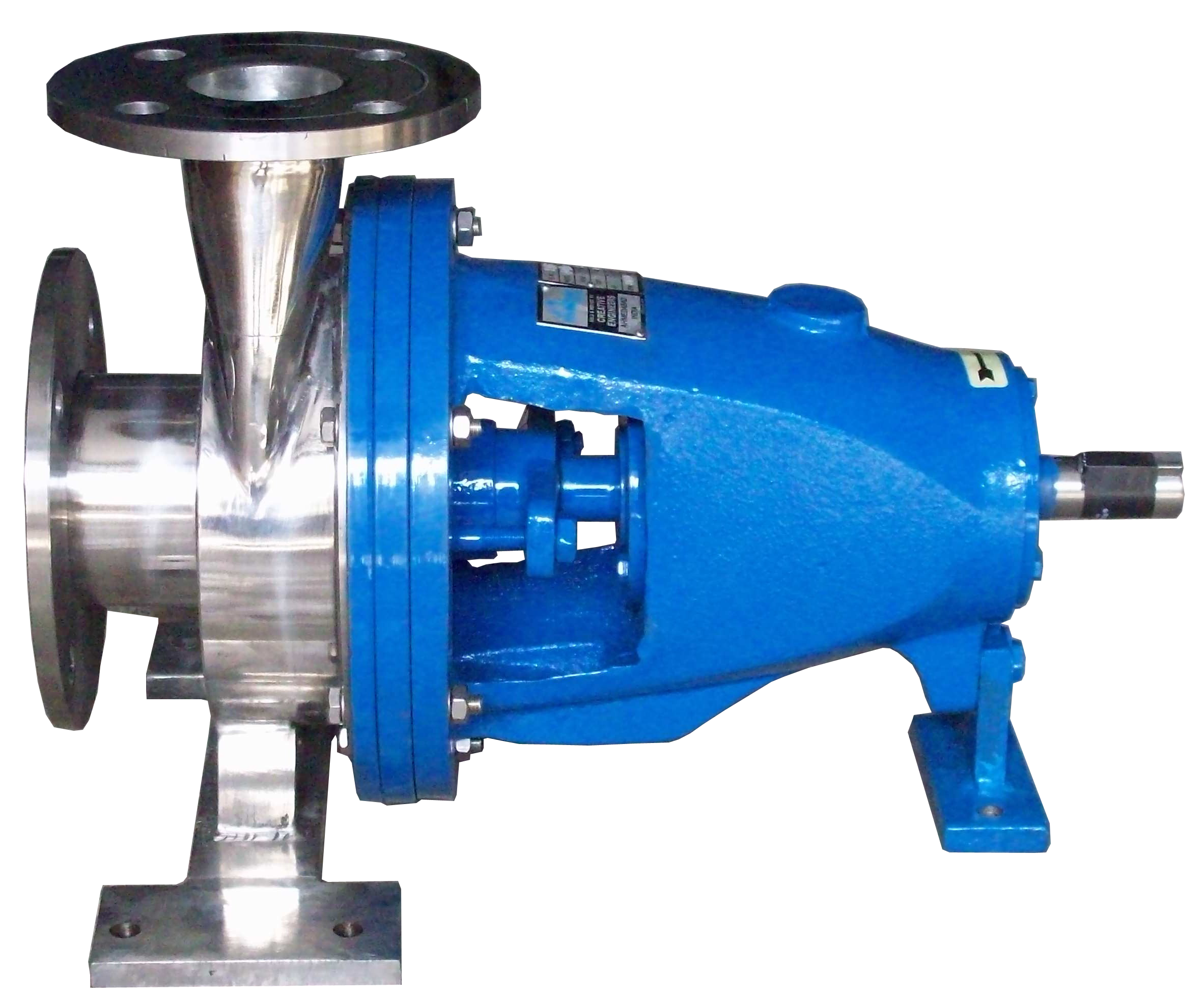

For over 25 years, We have been offering ISO-9001:2008 certified lobe pumps. We offer high-quality and hygienic stainless steel displacement pumps that can be used in the food processing industries. We supply a range of lobe pumps at the best price.

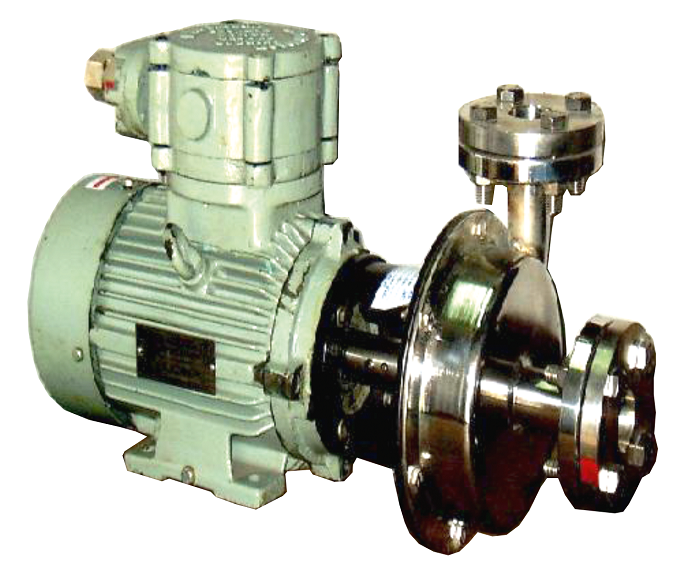

Pumping chambers are without pockets or crevices to harbor bacteria or contaminants. No Contact between moving parts and no internal bearings in the pump head. Solid stainless steel, AISI 316 quality, pump head, rotors and shafts. Food quality rubber covers and plastic rotors are also available. Robust, Cast Iron gear case enclosing oil Lubricated rolling bearings are precision timing gears. Generous distance separating the pump head from the gear case. End Connection / Port Flanged / Threaded - Customized.

Frequently Asked Questions

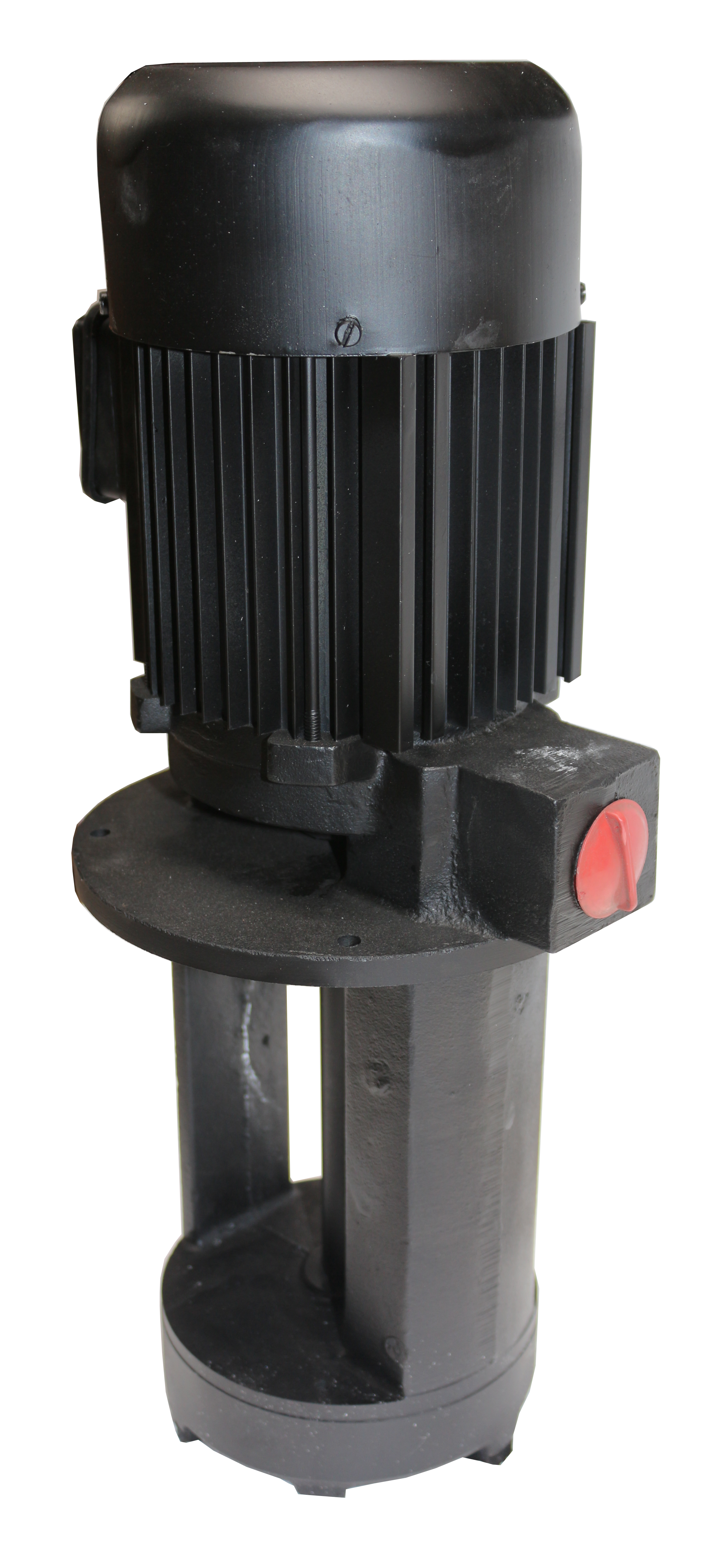

A lobe pump is a type of positive displacement pump that moves fluids using rotating lobes. It is widely used in industries such as food, pharmaceuticals, and chemicals due to its gentle handling of sensitive materials.

Lobe pumps operate by trapping fluid between the rotating lobes and the pump casing. As the lobes rotate, they create suction, drawing fluid in and then displacing it through the outlet. Since the lobes do not come into direct contact with each other, the pump ensures minimal product degradation.

Most lobe pumps are constructed from stainless steel or other corrosion-resistant materials to ensure durability and compliance with sanitary standards. Seals and elastomers are chosen based on the compatibility of the pumped fluid.

Regular maintenance includes inspecting seals, bearings, and lobes for wear, ensuring proper lubrication, and cleaning components to prevent contamination. Proper servicing helps extend the pump’s lifespan and maintain optimal efficiency.