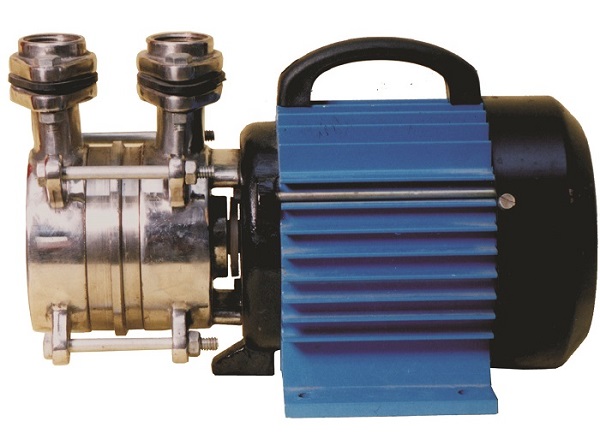

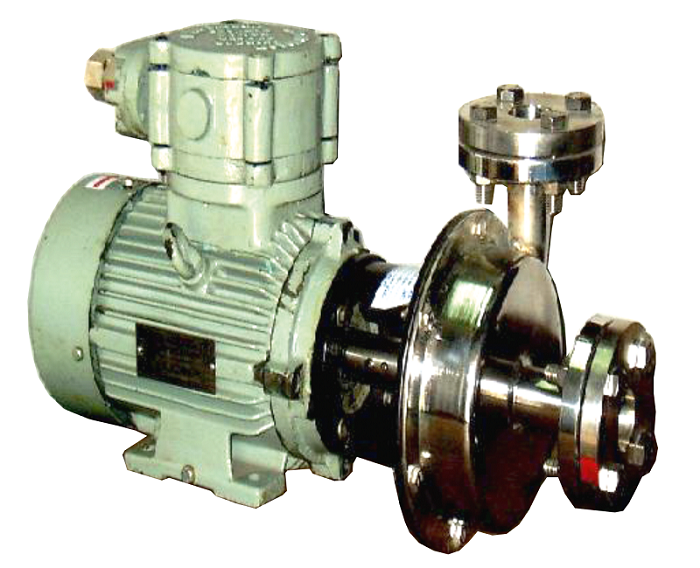

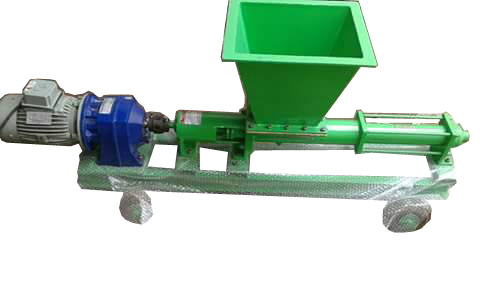

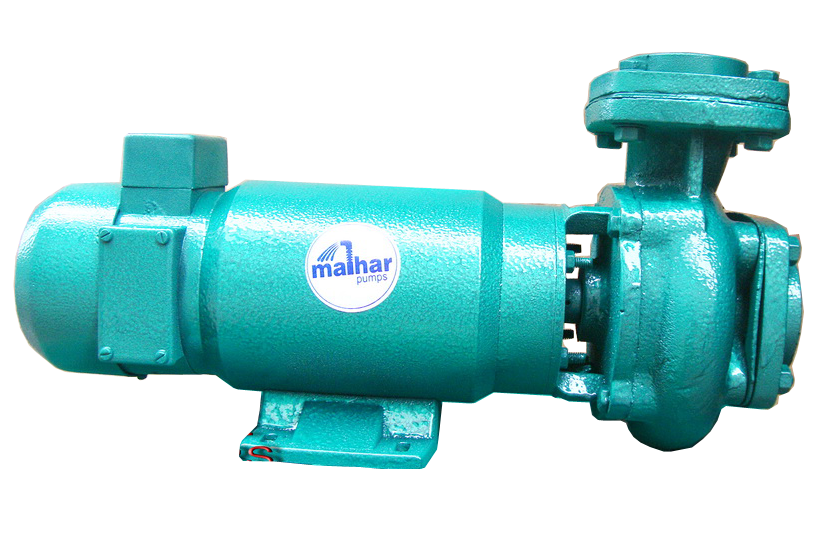

Glandless Pump

Glandless Pump Manufacturer

We are Leading Manufacturer of Glandless Pump, and Vertical Glandless Pumps in India

Glandless Pump Product Overview

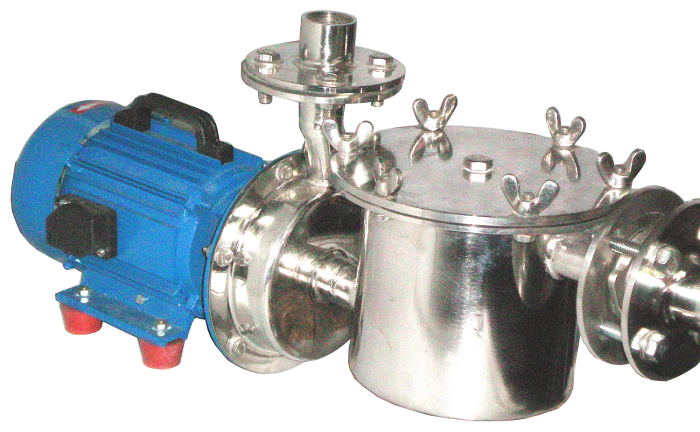

A glandless pump is a type of centrifugal pump that eliminates the need for a conventional gland packing or mechanical seal to prevent fluid leakage along the pump shaft. Instead of relying on these traditional sealing methods, glandless pumps use a tightly controlled magnetic field to create a barrier between the fluid being pumped and the external environment.

Glandless Pump Technical Specifiction

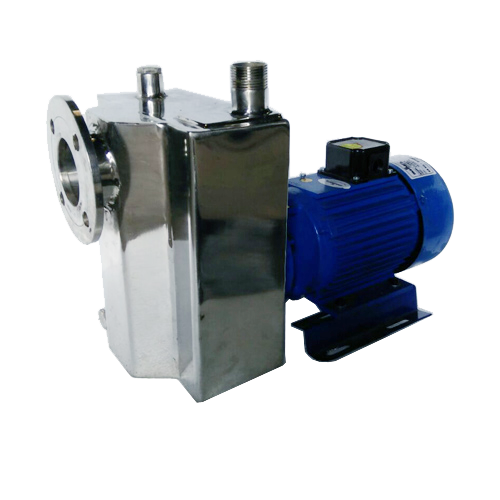

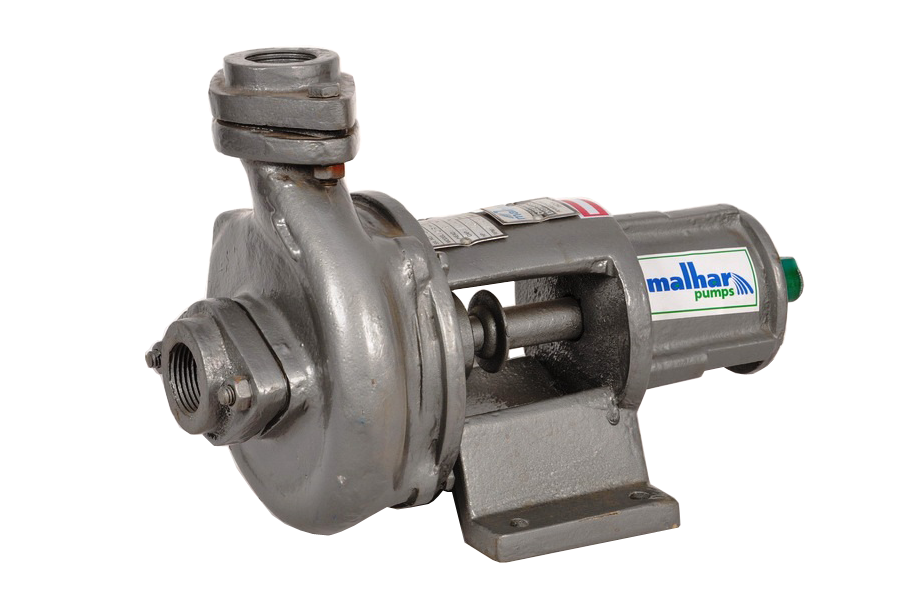

MVGP” Series Vertical Glandless Pump

Glandless Pump Application

- Water treatment Plant

- Effluent Treatment

- Filter Press for dyes and chemicals

- Fertilizer Plants Thermal and atomic power plants

- Drugs & Pharmaceutical Industries

- Descaling of Tubes

- Scrubbing of corrosive gases like Cl2 , Br , I, SO2 , NH3 , F2 Etc.

- Excellent for vacuum ejectors

- Transferring of concentrated HCL from road tankers

- Paper & Pulp industries

- Pickling in steel rolling mills

- Caustic soda plants:Chlorinated brine, conc. HCL, H2SO4 etc. Other application are in metal refineries, pickling Installations, paper and fertilizer

- plants-in fact all chemical process industries.

- Phosphoric Acid Plants:H3PO4 , H2SO4 , HF and their mixtures with or without solid (gypsum) up to 40% conc.

- Gas Washing Plants:Scrubbed liquids containing F, CL, SO2,

- Ammonia gases etc. With solids replace hast alloy.

- Rayon Plants:Spin bath solution (H2SO4 , ZNSO4 , NASO4 , etc.)

SALIENT FEATURES

- No mechanical seal, stuffing box and internal bearings is needed

- No maintenance since the pump can even run dry indefinitely as there is no packing, bushes or internal Bearings.

- Reduction of downtime production losses in view of above features.

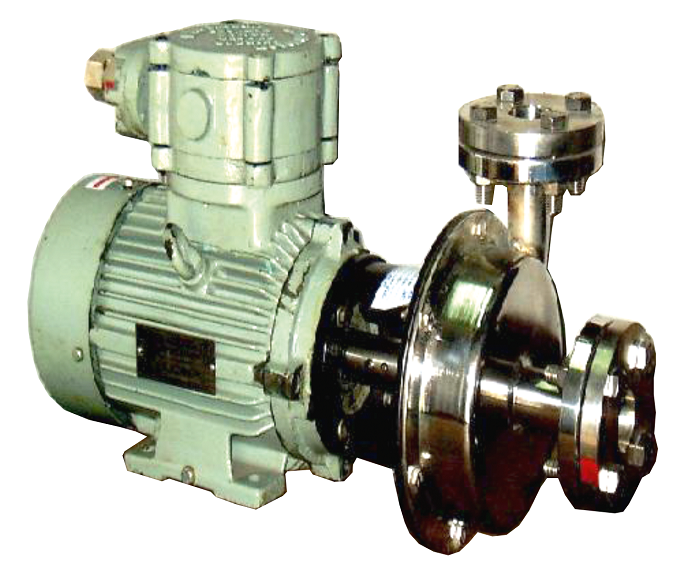

- All the wet-end parts are in solid molded construction to with stand corrosion and erosion.

- The impeller is semi-open type and used in our all-vertical pumps to suit both clear and polluted fluids.

- Pump mounted outside the suction tank and is not submerged type.

- Polypropylene is manufactured by solid injection molding process with high pressure

RANGE

- PP 50º TO 80 º C PPH 90 º TO 100 ºC PVDF 100º TO 115ºC

MATERIAL OF CONSTRUCTION

- CASTING: Top centreline discharge and integrated flanges, single piece, joint less casing formed out of Injection moulded polypropylene.

- IMPELLER: Hydraulically balanced and accurately matched to casing profile, the semi open type impeller with practical shroud and glass finished smooth flow passage ensure high efficiency low NPSH performance Impeller made from compressor moulded U.H.M.W

- EXPLORER: Made from U.H.M.W

- OVER FLOW BODY: Heavy duty, one piece, joint less design made from compressor moulded U.H.M.W

- SHAFT: The shaft is made from SS 316 protected by shaft sleeve of U.H.M.W