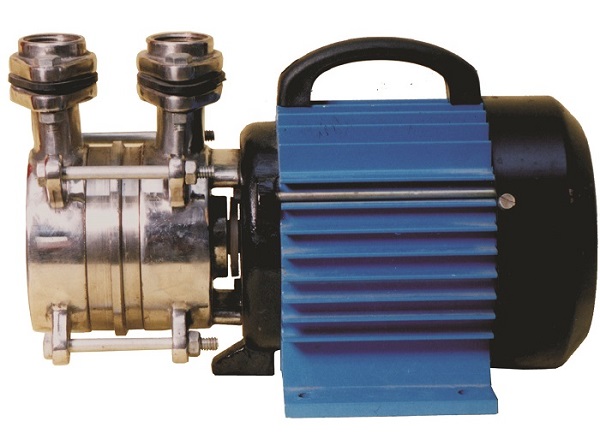

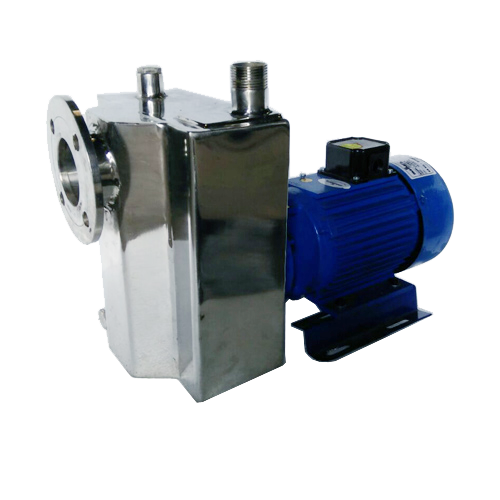

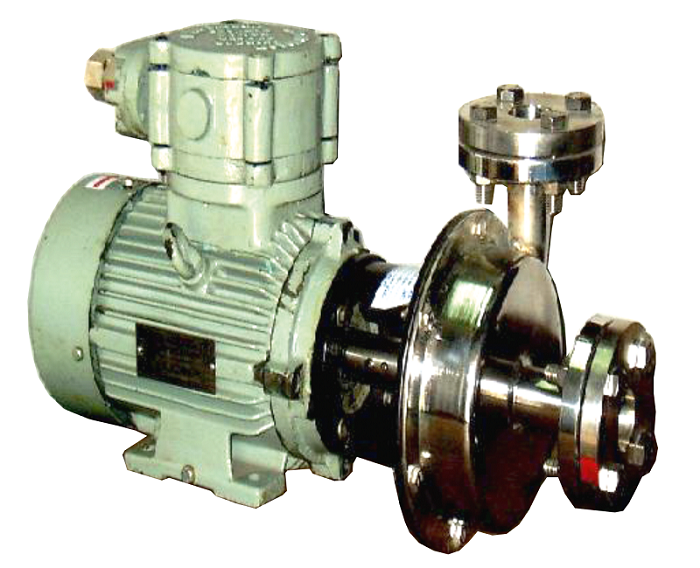

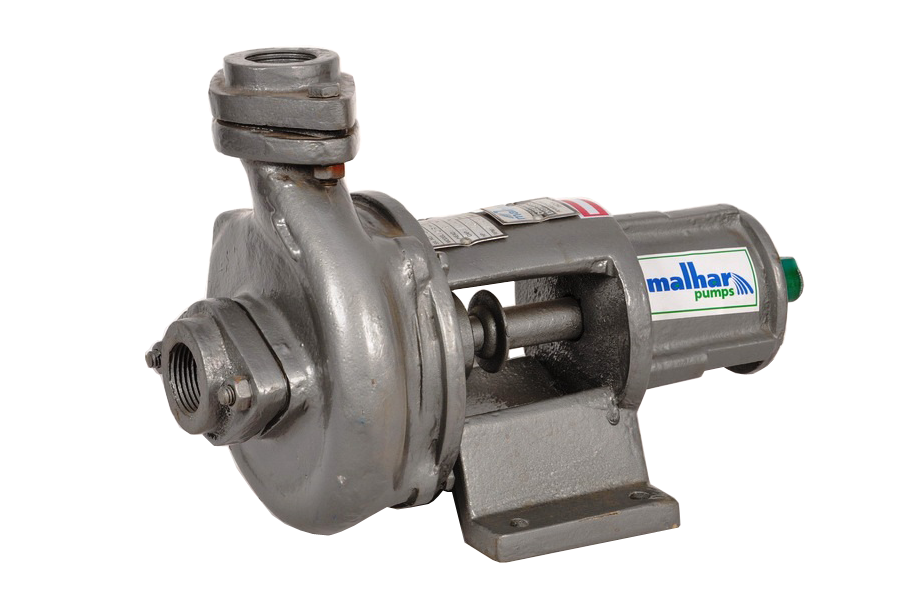

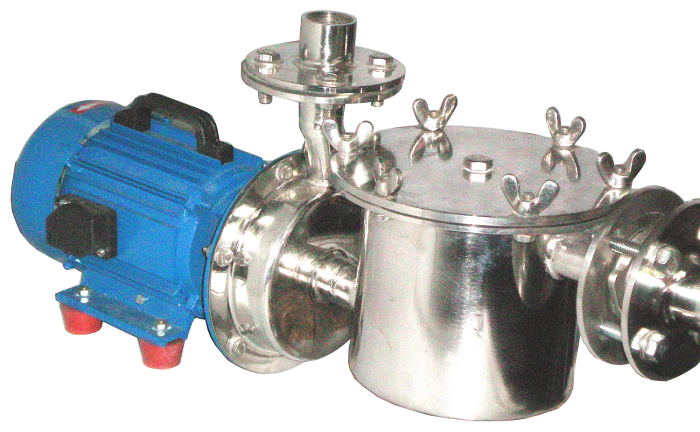

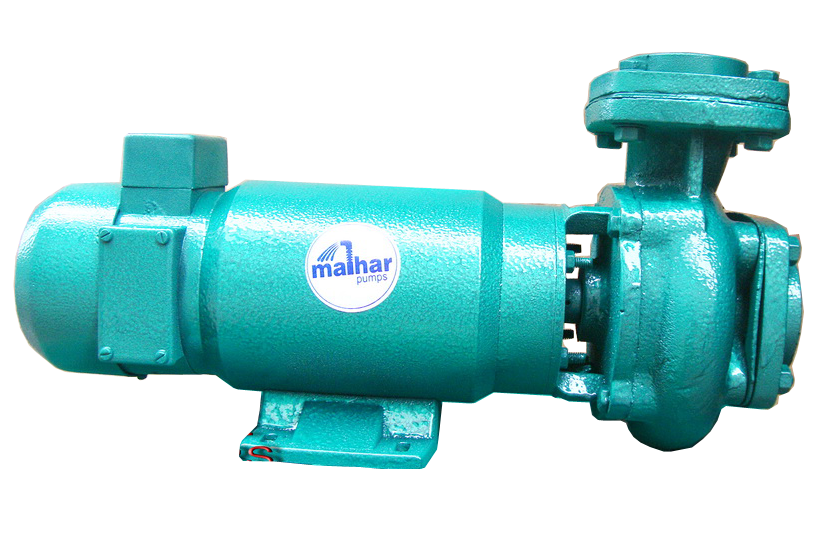

Horizontal Polypropylene Pumps

Horizontal Polypropylene Pumps Manufacturer

We are Leading Manufacturer of Horizontal Polypropylene Pump in India

Horizontal Polypropylene Pumps Product Overview

We are Leading Manufacturer of Horizontal Polypropylene Pump in India

Horizontal Polypropylene Pumps Technical Specifiction

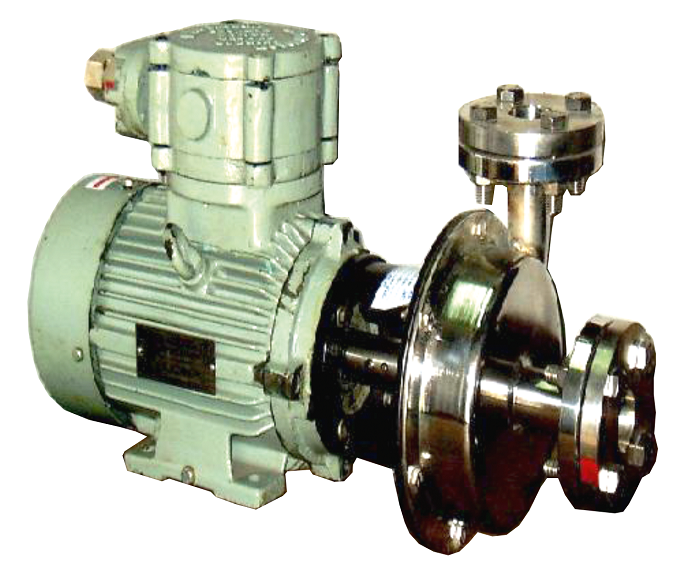

APPLICATION

- Water Treatment Plant

- Effluent Treatment

- Filter Press for Dyes and Chemicals

HORIZONTAL POLYPROPYLENE

- Fertilizer Plants Thermal and atomic power plants

- Drugs & Pharmaceutical Industries

- Descaling of Tubes

- Scrubbing of corrosive gases like Cl2, Br, I, So2, NH3, F2 Etc.

- Excellent for vacuum ejectors

- Transferring of concentrated HCL from road tankers

- Paper & Pulp industries

- Pickling in steel rolling mills

- Electro Plating

- Caustic soda plants: Chlorinated Brine, Conc. HCL, Dilute H2SO4, etc.

- Chlorinated Brine, Conc. HCL, Dilute H2SO4 etc.

- PHOSPHORIC Acid Plants: H3PO4, H2SO4, HF and their mixtures with or without solid (gypsum) up to 40% conc.

- Gas Washing Plants: Scrubbed Liquids containing CL2, BR2, F2, I2, SO2, SO3, CO2, NH3, Gases, etc. with solids replace Hast Alloy.

- Rayon Plants: Spin bath solution (H2SO4, ZNSO4, NaSo4, etc.)

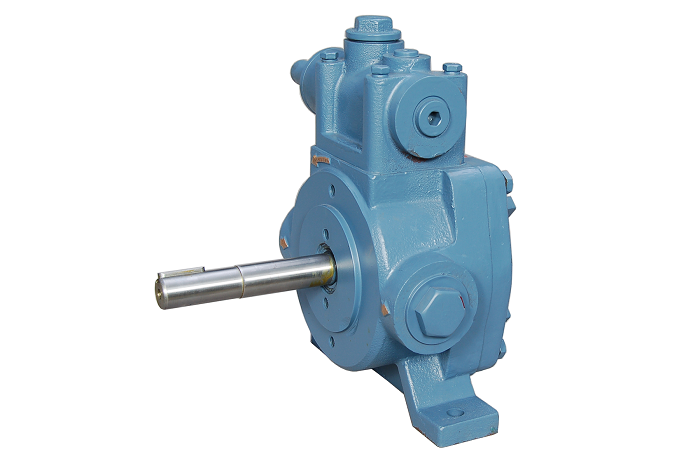

MATERIAL OF CONSTRUCTION

- CASING: Top centerline discharge and Integrated flanges , Single piece, joint less casing formed out of Injection-molded polypropylene / PVDF / UHMWPE.

- IMPELLER: Hydraulically balanced and accurately matched to casing profile, the semi-open type impeller with particle shroud and glass finished smooth flow passage ensure high-efficiency low NPSH Performance Impeller made from compressor molded polypropylene PVDF/UHMW.

- SHAFT: The shaft is made from SS 304 protected by shaft sleeve of alloy -20 or alumina field Teflon or ceramic.

- BEARING HOUSING: Made from heavy-duty graded casting.

- BEARING: SKF Ball Bearing

- MECHANICAL SEAL: Rotary part of the seal is made from glass field Teflon & Stationary part of the seal is made from high alumina field ceramic.

- DISTANCE PIECE: Heavy-duty one-piece injection-molded polypropylene.

RANGE

- Head-Up To: 60 meters

- Pump size: 25 mm to 150 mm

- Capacity: 180 M3/hr

- Speed: 1440/2880 rpm at 50 Hz &

- 1750/3500 rpm at 60 Hz

- Temperature: up to 110c

TEMPERATURE RESISTANCE

- PP 50 TO 80c

- PPH 90 TO 100c

- PVDF 100 TO 115c