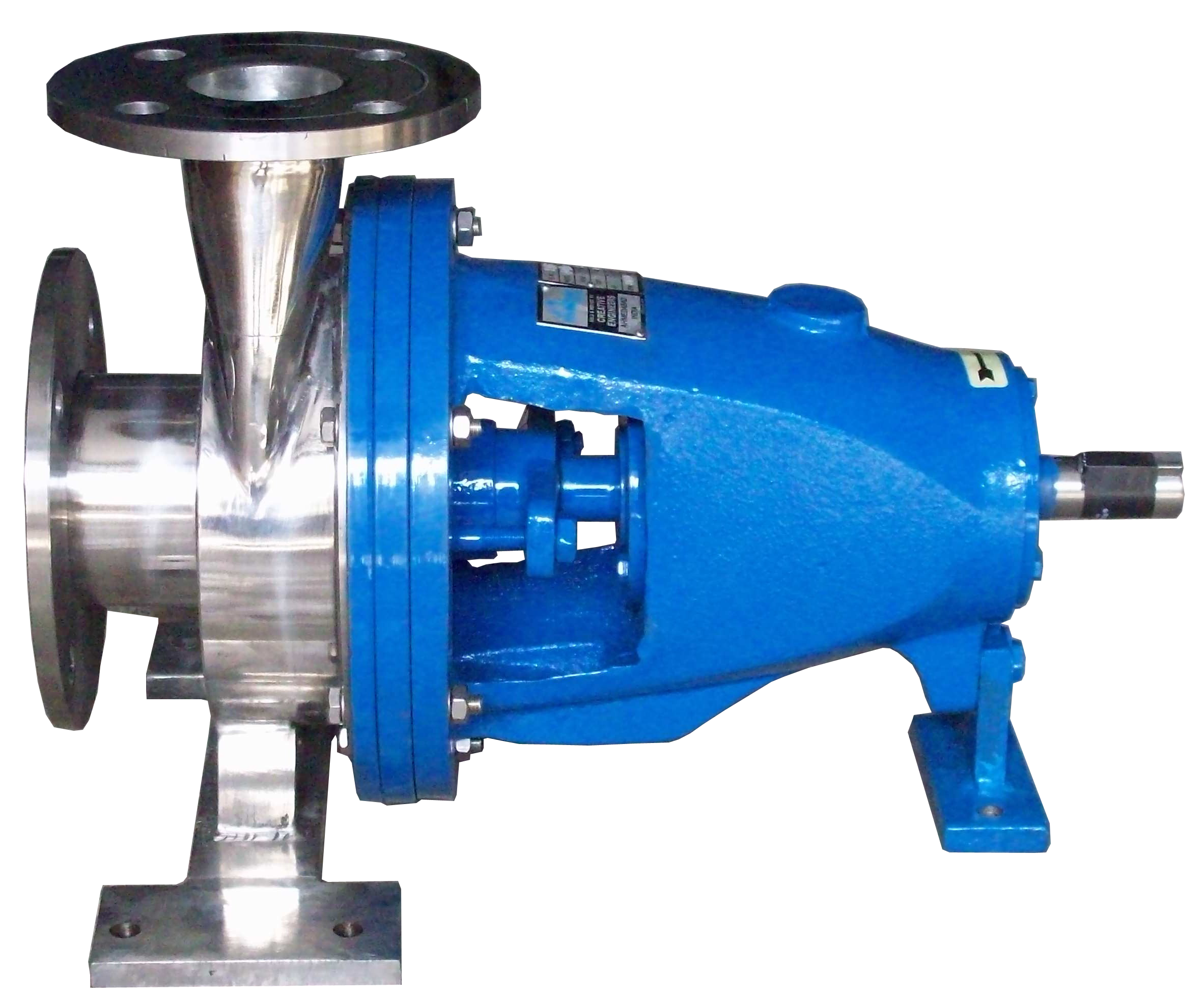

PP Sealless Pump Manufacturer

Are you searching for PP Sealless Pump Manufacturer in India? Look no further than Creative Engineers, your trusted partner for high-performance fluid handling solutions. We specialize in SS Magnetic Sealless Pumps, PVDF Sealless Pumps, and PP Sealless Pumps, ensuring leak-free, efficient, and reliable operation across industries.

Our advanced sealless magnetic drive pumps guarantee zero leakage, minimal maintenance, and long-lasting durability, making them use for applications requiring high chemical resistance and operational efficiency. With a strong commitment to quality and innovation, Creative Engineers delivers precision-engineered pumps tailored to industrial needs. As a leading pp sealless pump manufacturer, supplier, and exporter, We offer top-notch solutions for chemical processing, pharmaceuticals, water treatment, and more.

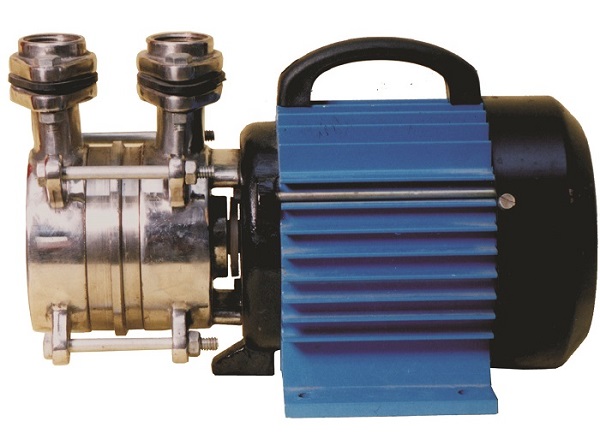

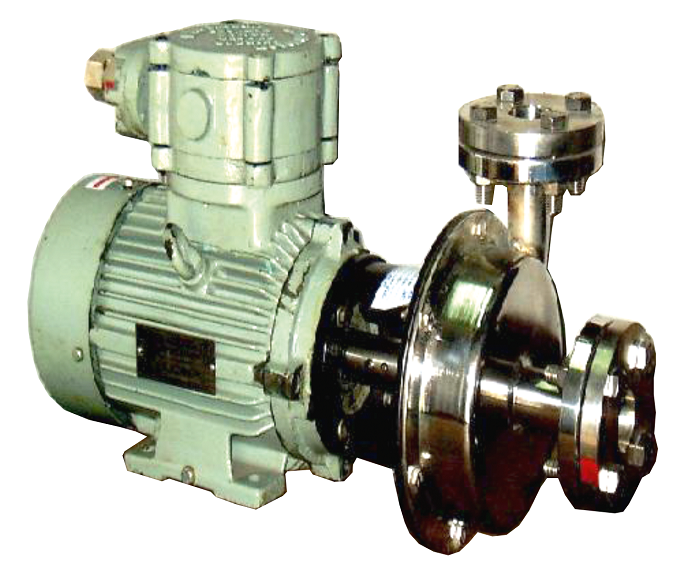

SS Magnetic Sealless Pump Manufacturer

A ss magnetic sealless pump offers leak-free operation by using a magnetic coupling to transfer torque, eliminating the need for shaft seals. It provides excellent chemical resistance, making it ideal for handling corrosive and hazardous fluids. With minimal maintenance requirements, high efficiency, and reliable performance, magnetic pumps ensure safe, clean, and cost-effective fluid transfer across a wide range of industries.

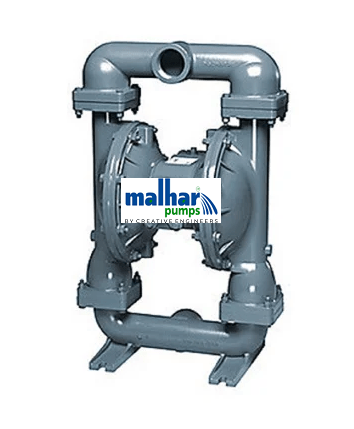

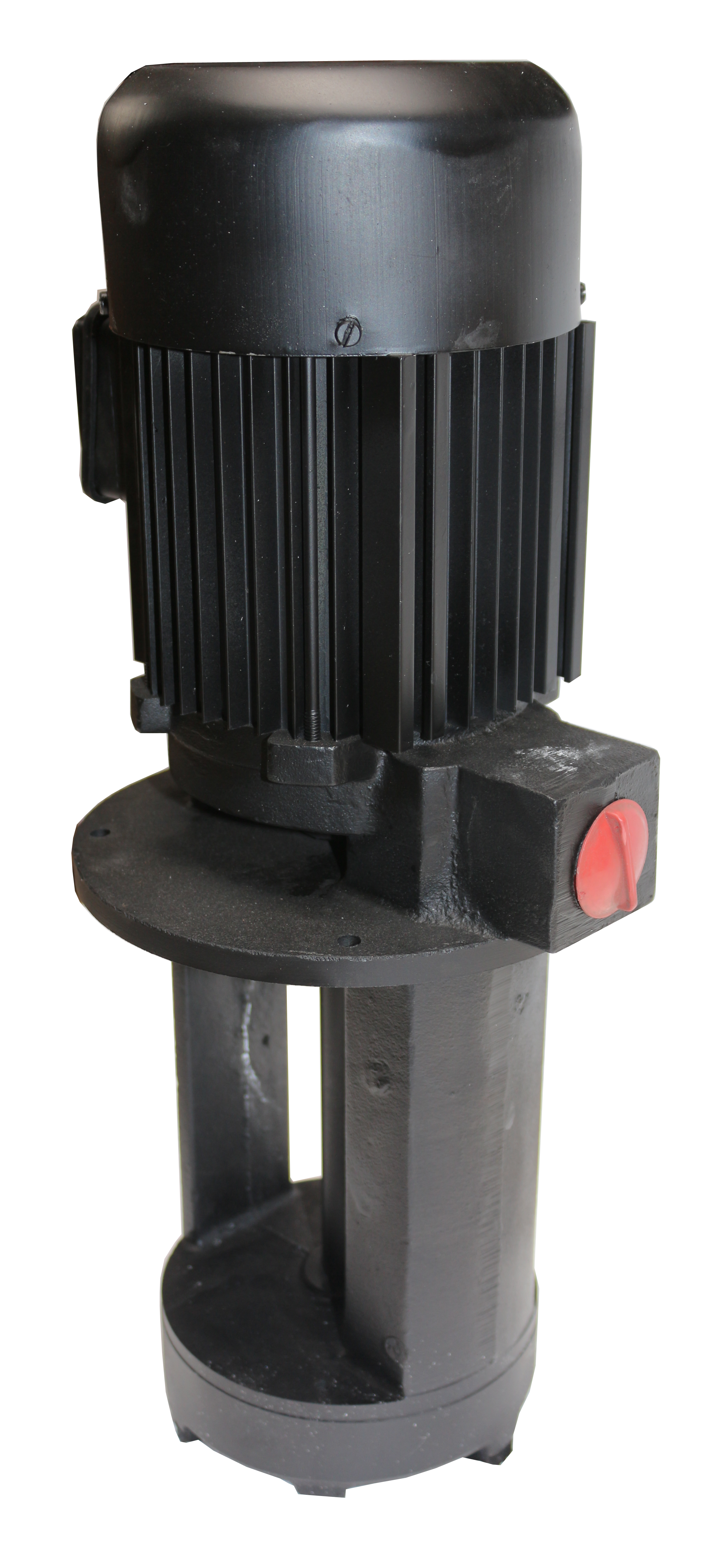

PVDF Sealless Pump Manufacturer

The PVDF Sealless Pump is a highly efficient and corrosion-resistant fluid transfer solution, designed for industries handling aggressive chemicals and high-purity liquids. Built with Polyvinylidene Fluoride (PVDF), this pump offers exceptional chemical resistance, making it ideal for applications such as chemical processing, wastewater treatment, and pharmaceutical production.

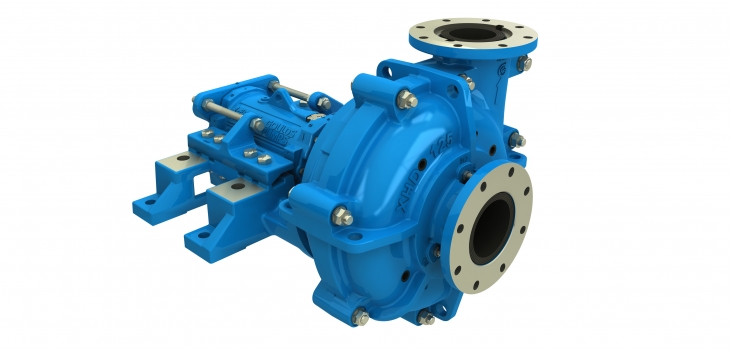

Applications & User Industries

Ideal for the transfer of corrosive chemicals, plating chemicals, acids, dyes, solvents, toxic & fuming liquids, petrol, kerosene, etc. Useful in chemical industries, pharmaceuticals, and food processing industries. Electroplating, Galvanizing / Anodizing plants. Laboratory equipment and PCB plants. Medical equipment and X-Ray film plants. Textile Dyeing houses. Liquid dispensing machines and Chemical Filtration equipment. For hazardous duty conditions with flameproof motors. High Efficiency due to permanent magnet power coupling.

Advantageous Features

100% Leak Proof pumps due to a magnetic drive arrangement. No shaft seal is used which automatically solves the problem of seal leakage and wear & tear. Friction free operation for reduced power consumption. High power permanent magnets ensure full power transfer and eliminate slippage. All pumping parts are Non-metallic, Which gives superior corrosion resistance, Simple and easy to operate, has Long life, is reliable and has trouble free operation

Sealless Pump Range

- Capacity: from 10 LPM up to 750 LPM

- Head: upto 40 mtrs.

- The material of Construction: Poly Propylene Glass Filled , PVDF upto 110 Deg C & SS-316

- Operating Temp: PP upto 80 deg C , PVDF upto 110 deg C Special Pumps for high temperature upto 150ºC and 250ºC for SS-316

Frequently Asked Questions

A sealless pump is a type of pump that operates without a mechanical seal, using magnetic drive or canned motor technology to eliminate leakage risks.

While the initial cost may be higher, the lower maintenance, increased reliability, and elimination of seal-related failures often result in long-term cost savings.

Sealless pumps require minimal maintenance, primarily involving periodic inspection, cleaning of internal components, and monitoring for wear in bushings or bearings.

A magnetic pump, also known as a mag drive pump, uses a magnetic coupling to transfer torque from the motor to the pump without direct mechanical contact, eliminating the need for a shaft seal.

They are widely used in chemical processing, pharmaceuticals, food and beverage, water treatment, and industries requiring the safe transfer of corrosive, toxic, or valuable fluids.

Yes, many magnetic pumps are specifically designed to handle a wide range of temperatures and viscosities, but it is important to choose the right model based on the application requirements.

Download Brochure

Download Brochure