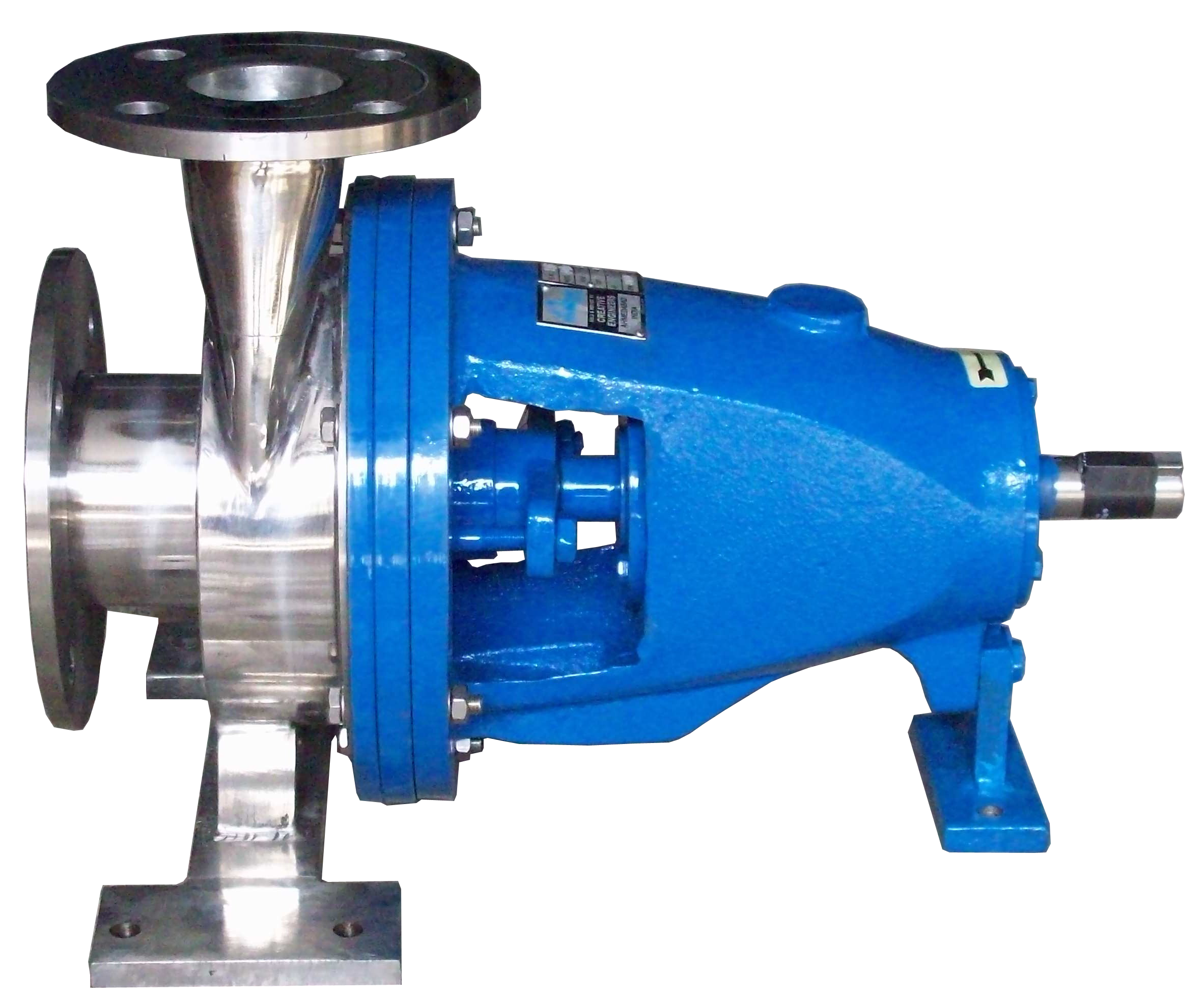

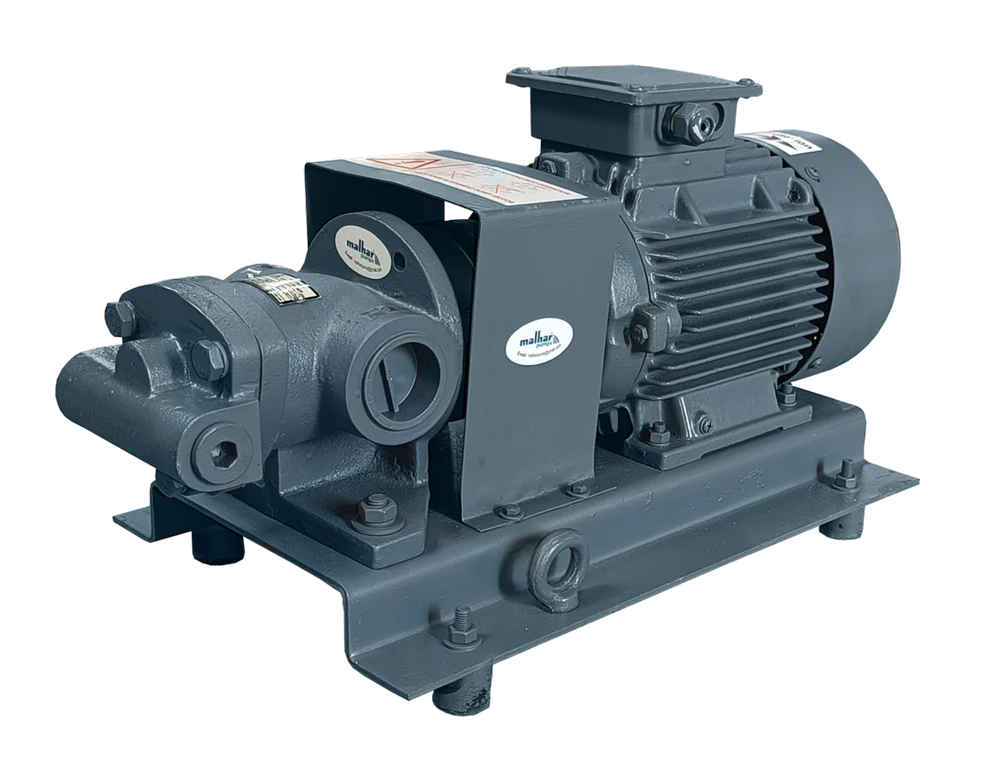

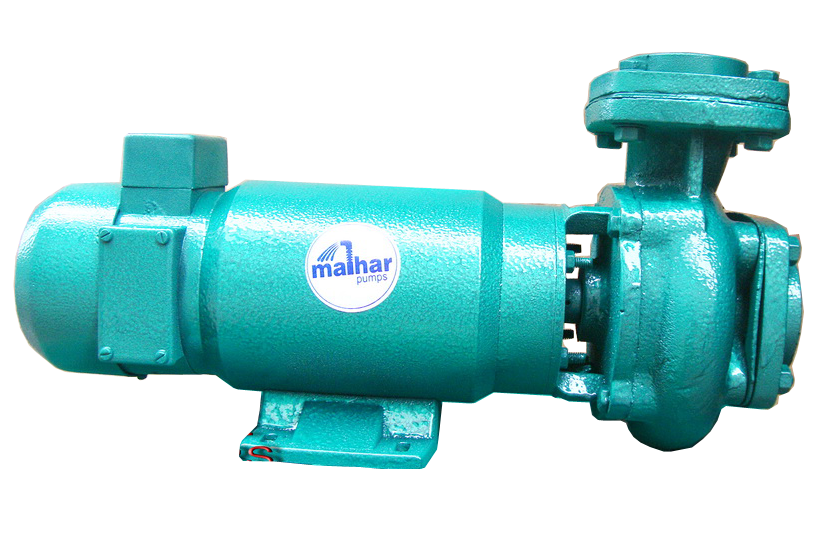

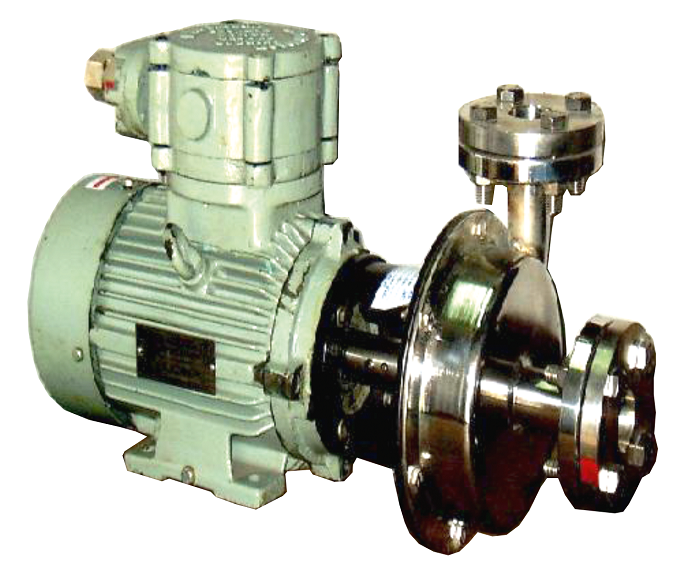

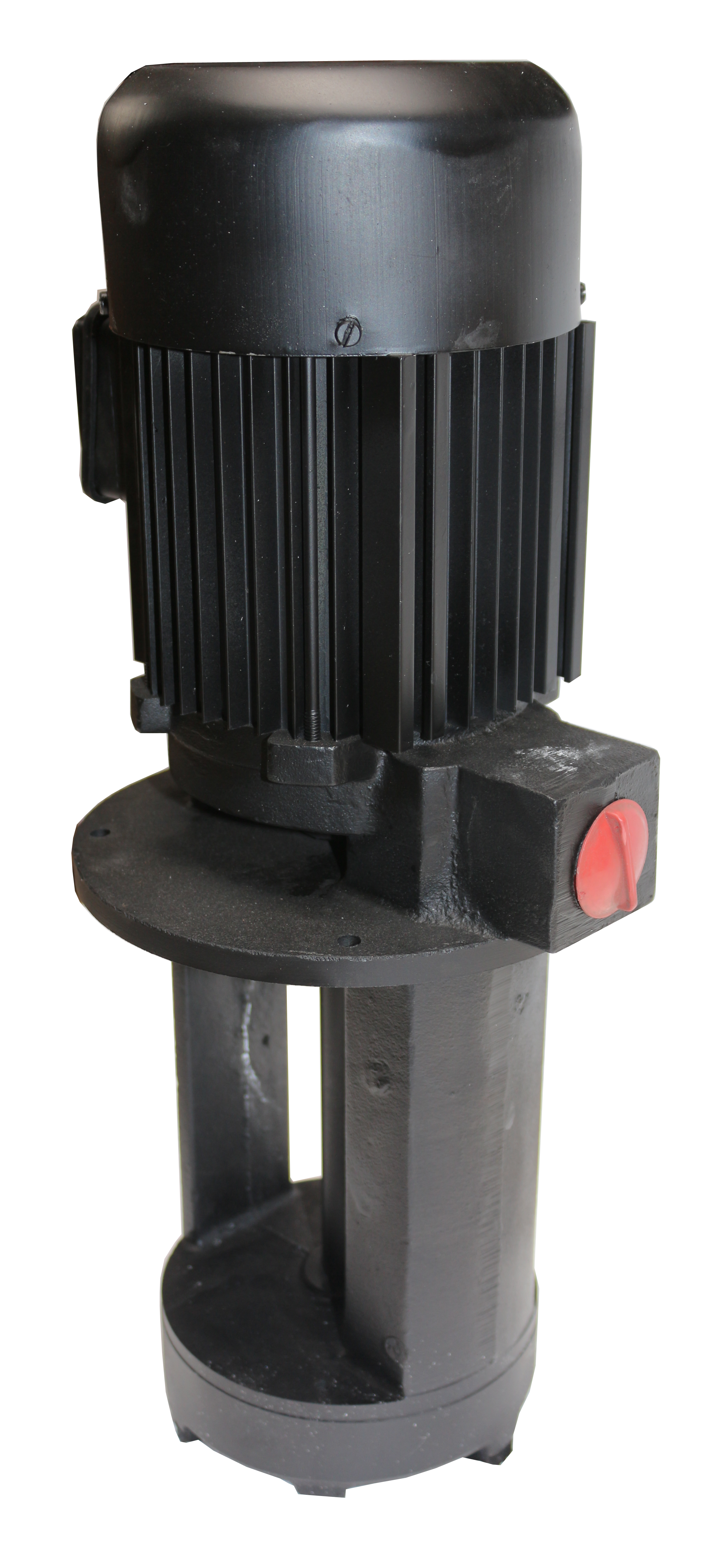

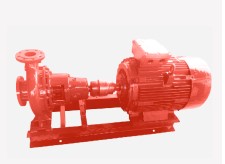

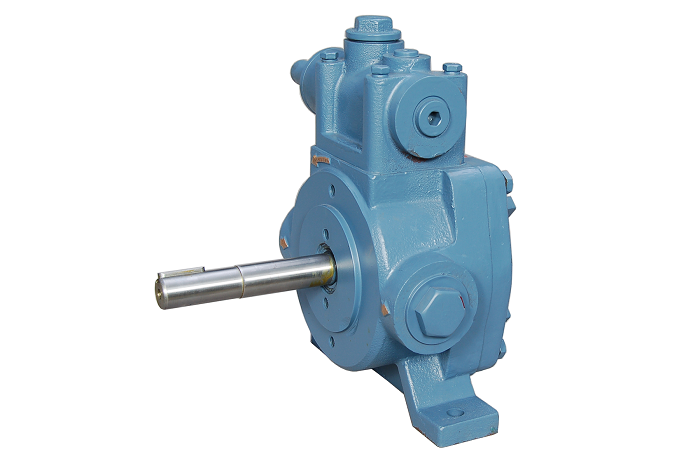

An Internal Lobe Gear Pump is a highly efficient positive displacement pump designed for handling high-viscosity fluids with precision and reliability. It is widely used in industries such as chemical processing, food & beverage, pharmaceuticals, and automotive manufacturing.

Internal Lobe Gear Pump Manufacturer

Looking for Internal Lobe Gear Pump Manufacturer, Supplier, and Exporter in India? Choose Creative Engineers, your trusted partner for high-quality, precision-engineered internal lobe gear pumps designed for efficient fluid transfer across industries such as chemical processing, pharmaceuticals, and food production.

Internal Lobe Gear Pump Features

- Smooth Fluid Transfer: The pump operates with minimal pulsation, ensuring a steady and controlled flow.

- High Efficiency: Designed for low energy consumption while maintaining optimal performance.

- Self-Priming Capability: Can handle fluids with varying viscosities, including thick liquids like syrups, oils, and adhesives.

- Compact & Durable Design: Built with robust materials to withstand demanding industrial applications.

- Precise Metering: Ideal for applications requiring accurate dosing and mixing.

- Low Maintenance: Fewer moving parts reduce wear and tear, ensuring long service life.

Internal Lobe Gear Pump Benefits

- Enhanced Process Control: Provides consistent flow rates, making it suitable for metering and dosing applications.

- Versatile Fluid Handling: Works efficiently with shear-sensitive fluids, preventing degradation.

- Reduced Operational Costs: Energy-efficient design lowers power consumption.

- Improved Equipment Longevity: Minimizes pressure fluctuations, protecting downstream equipment.

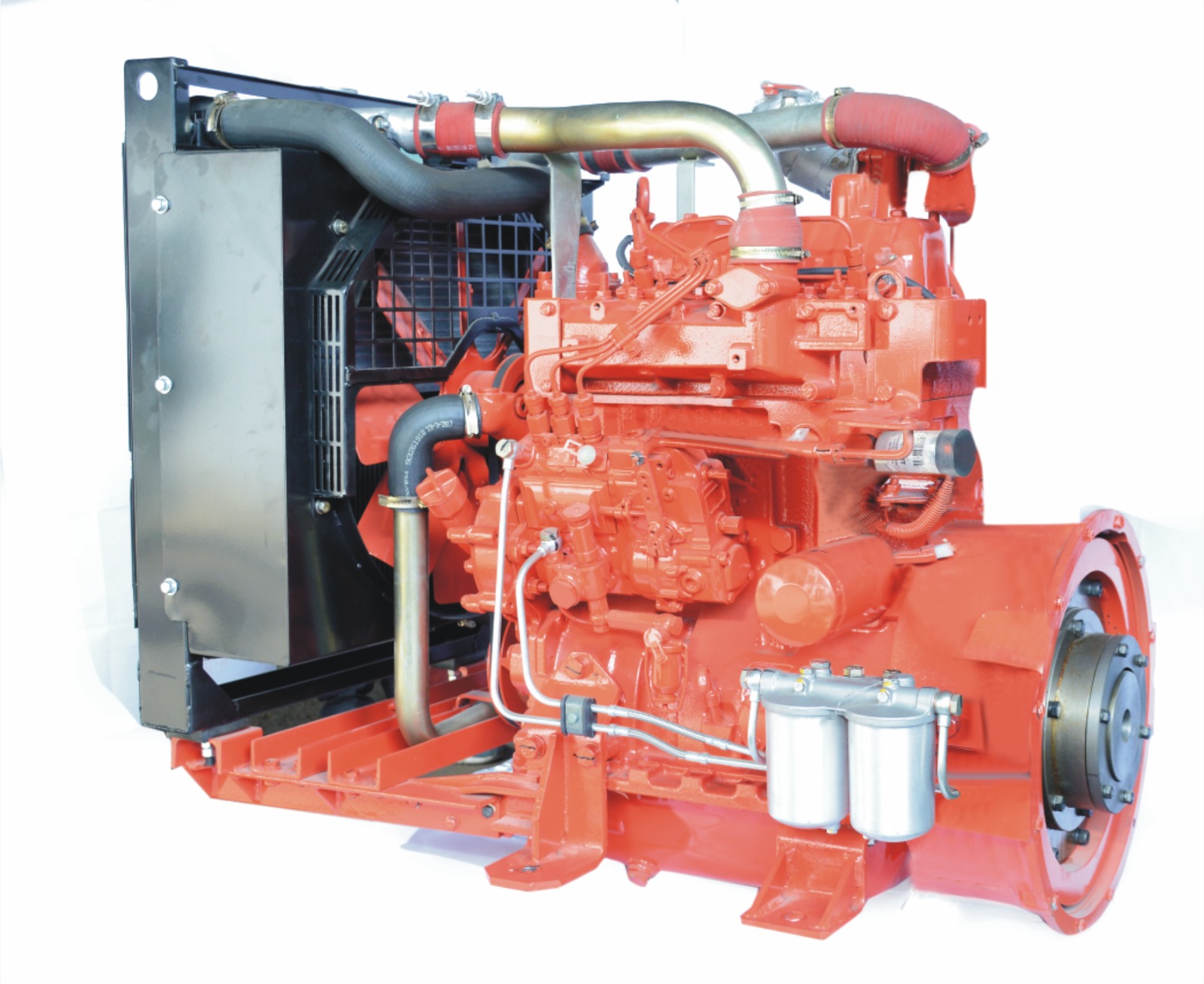

- Application Flexibility: Suitable for high-pressure and high-temperature environments.

Frequently Asked Questions

An internal lobe gear pump is a type of positive displacement pump that uses intermeshing lobes to transfer fluids efficiently with minimal pulsation.

Yes, they are self-priming and can maintain consistent flow even with varying fluid viscosities, making them suitable for a wide range of operating conditions.

Regular maintenance includes checking for wear on the lobes and seals, ensuring proper lubrication, and inspecting for contamination or clogging within the pump housing.

Yes, regular maintenance such as checking for wear, ensuring proper lubrication, and inspecting seals is essential to maintain performance and extend pump life.

Download Brochure

Download Brochure