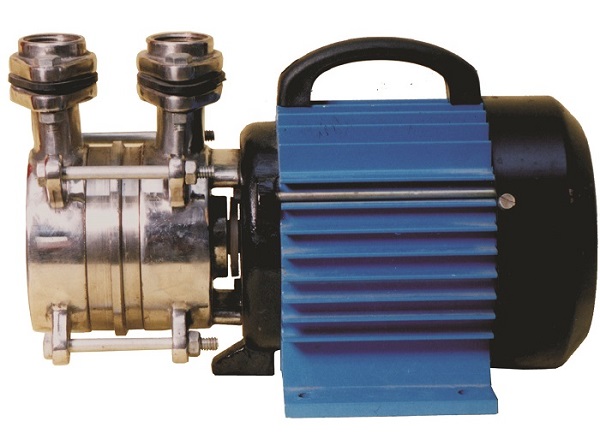

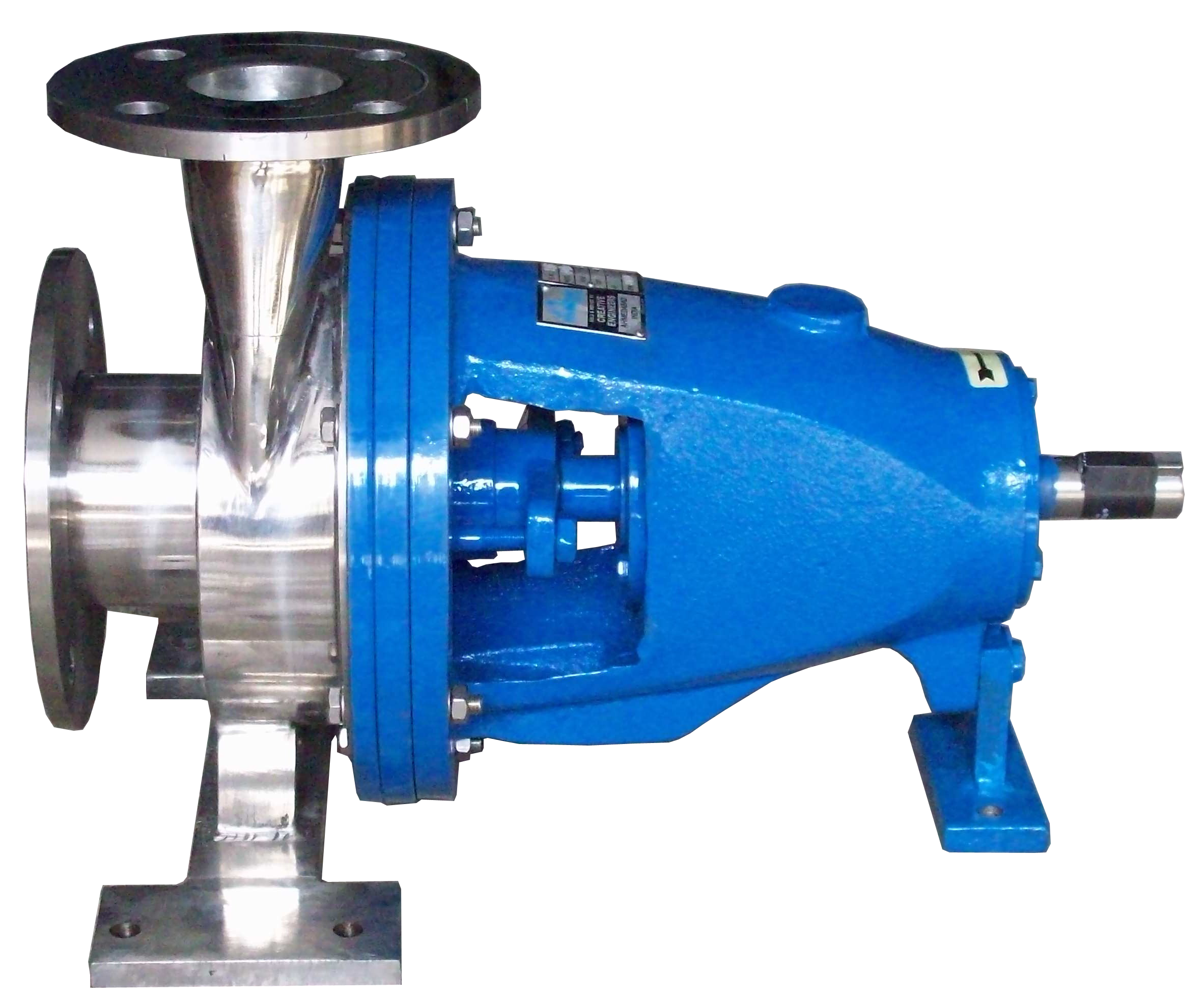

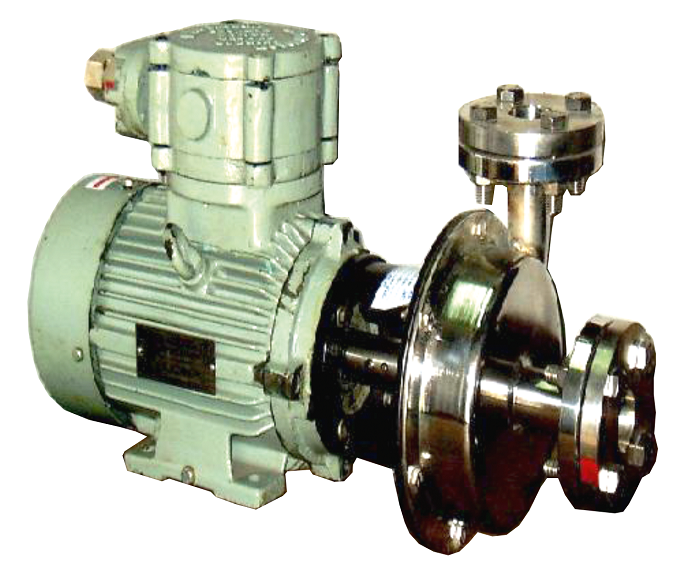

Chemical Transfer Pump Manufacturer

Are you looking for reliable Chemical Transfer Pump Manufacturer, Supplier, and Exporter from Ahmedabad, India? Creative Engineers is the perfect choice for you. We specialize in high-quality chemical transfer pumps designed for efficient and safe handling of corrosive and hazardous liquids. Our pumps durability, high performance, and low maintenance, making them ideal for industries. With advanced technology and precision engineering, we deliver top-notch solutions at competitive prices.

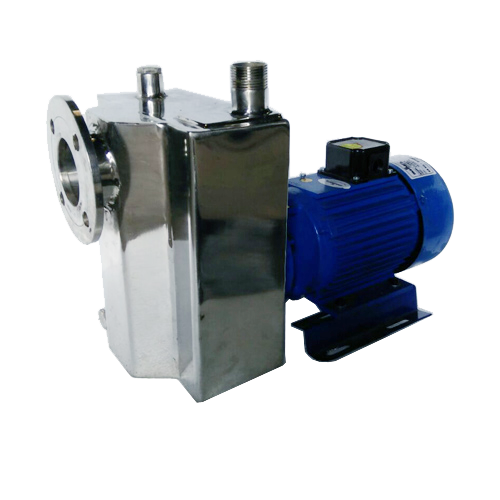

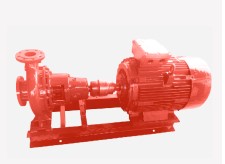

APPLICATION

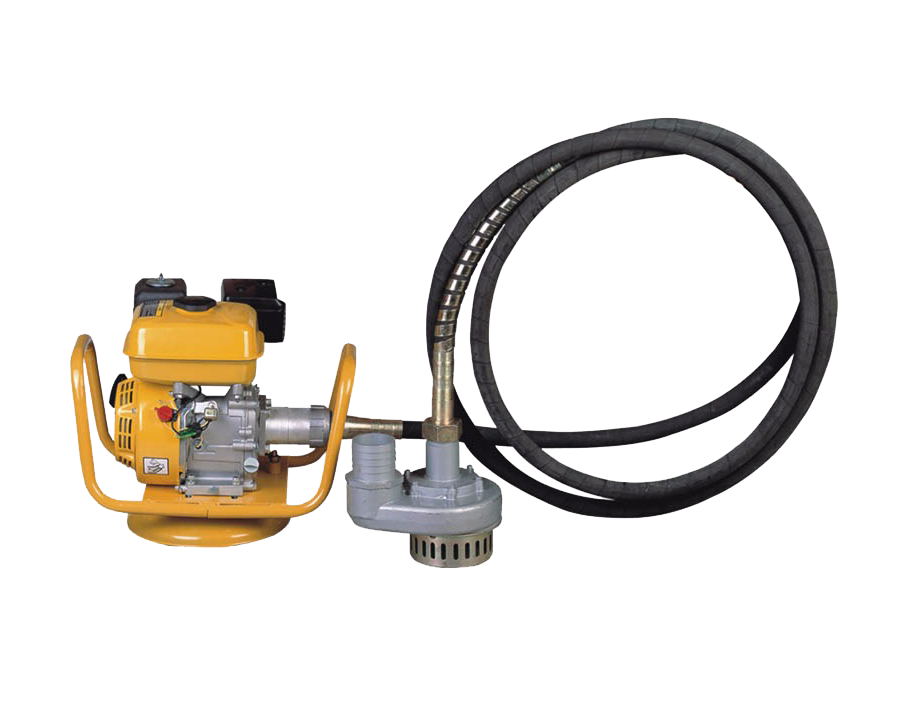

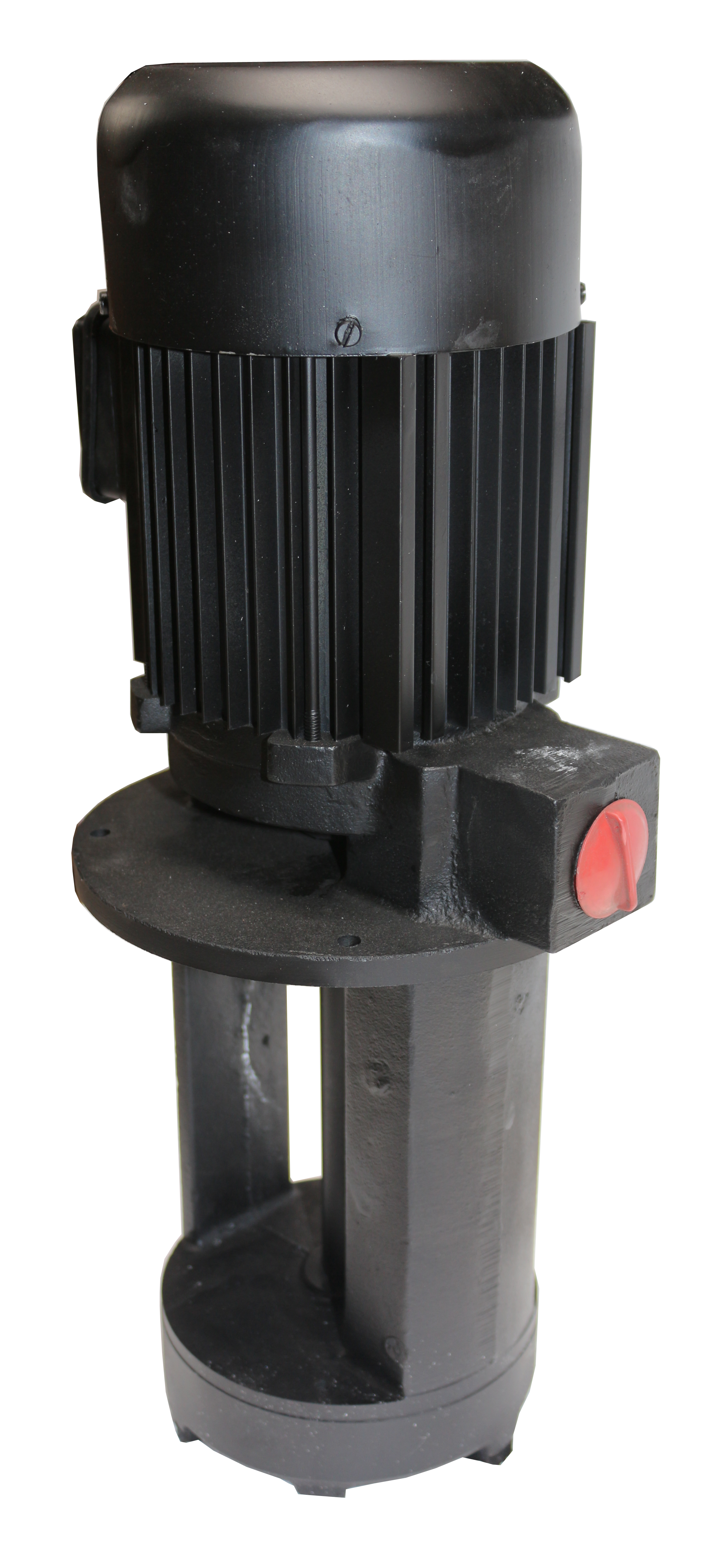

For pumping Clear / Turbid water / Chemicals & Volatile Liquids.

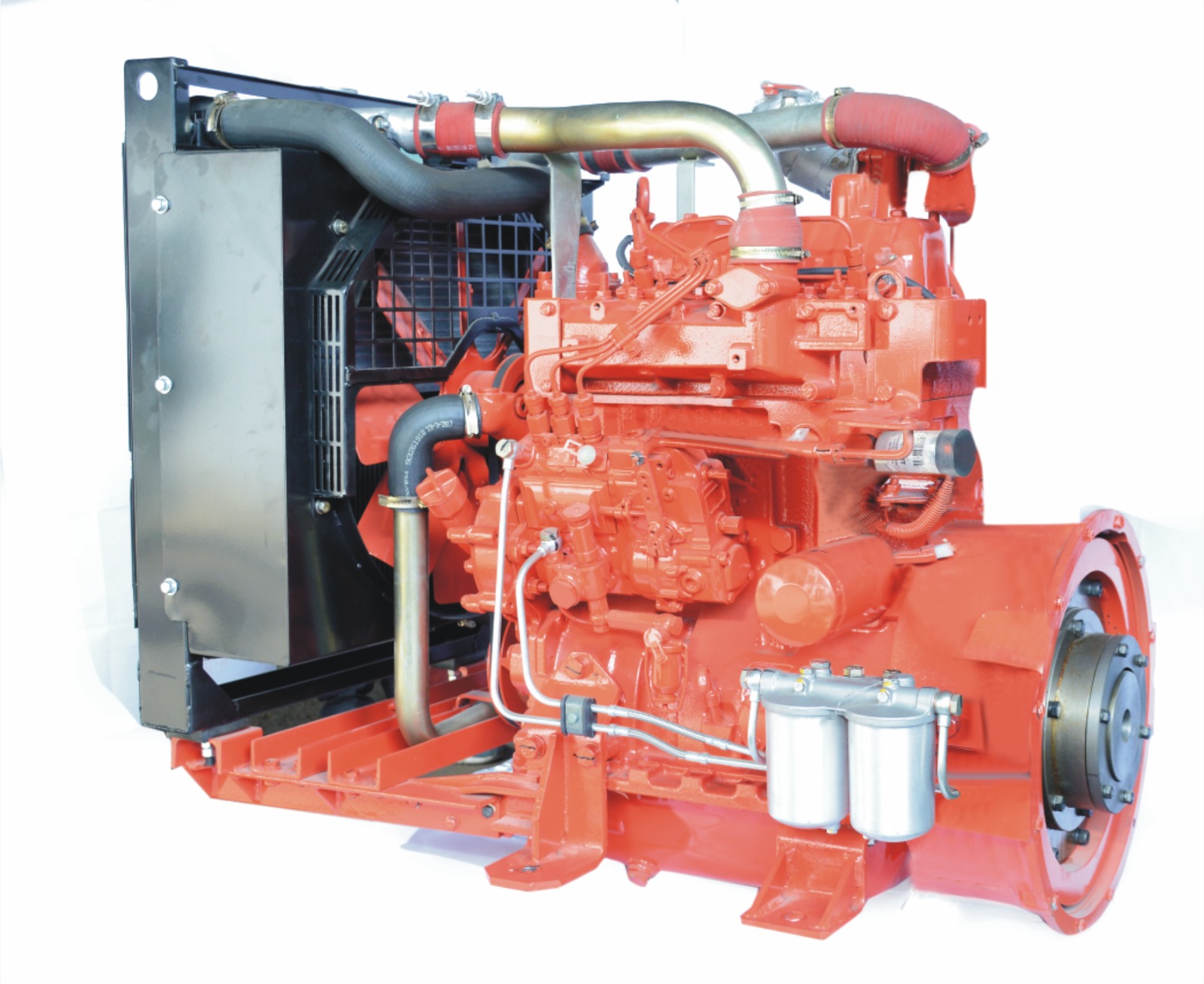

Air conditional plants , power station , Mine Drainage , Sprinkle systems fire fighting , Booster service , Oils Brine.

STANDARD : AS PER DIN 24255/6 & ISO 2858

OPERATING RANGE

• Delivery size up to 250 mm

• Capacity up to 990M/hr

• Head up to 120 meters

• RPM 500 to 3600

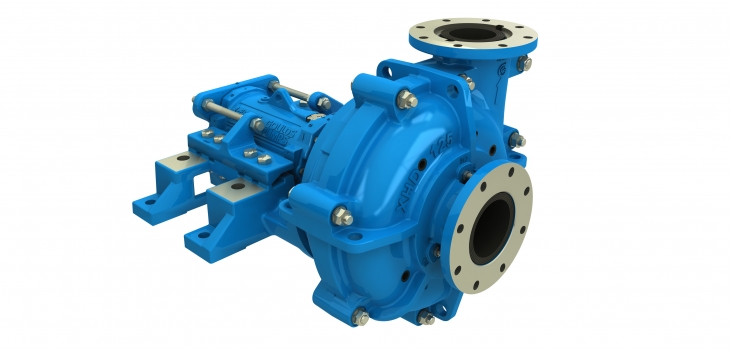

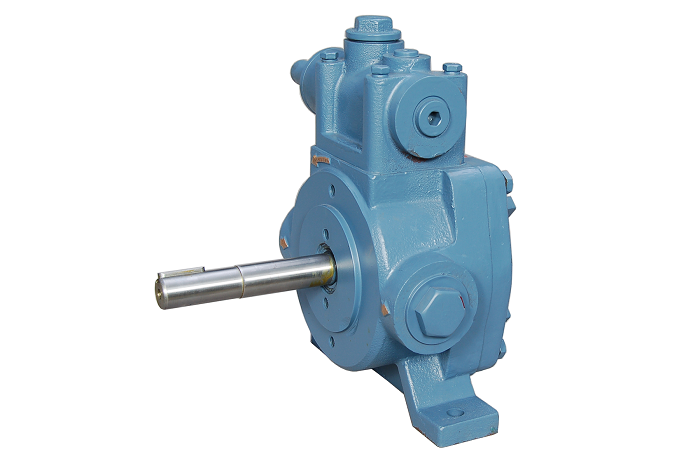

“ACH” SERIES BACK PULLOUT PUMPS (SLURRY APPLICATION)

• “ACH” Type pumps are used in Chemical & Petrochemicals Industry, Food Industry, Dyeing , Sugar Industry, Paper & Pulp Industry, Fertilizer Units & Etc.

• Handling of all types of Liquids , Acids , Alkalis , Dyes , Hydrocarbons ,Corrosive Slurries (Solids Up to 15 mm) , Green , Black Liquor , Pulp (Consistency up to 2%) & Etc.

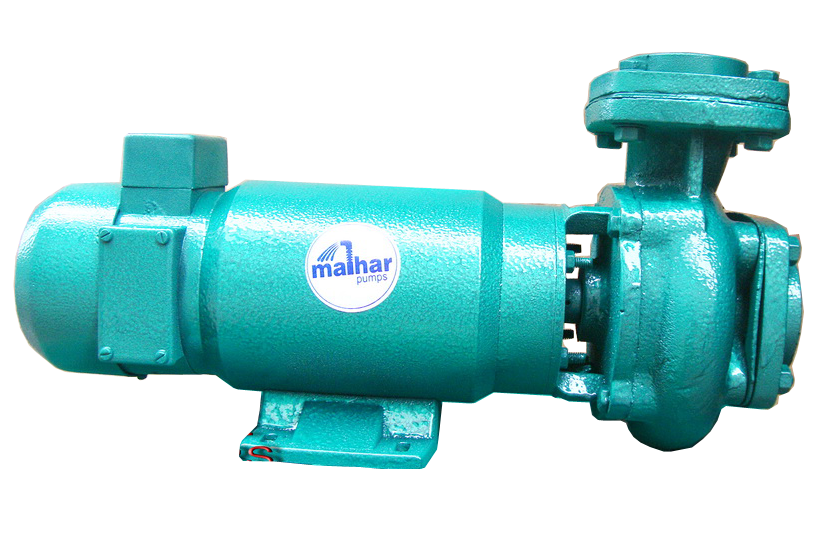

“PS” SERIES BACK PULLOUT PUMPS (PULP APPLICATION)

"PS” Type pumps are used in paper & pulp industry, food industry, sugar industry, efficient plants, sea water desalination plants, chemical & petrochemicals industry, power stations and absorption plants in environmental engineering & etc.

Handling of pulp & paper stocks up to 5% consistency heavily contaminated liquids, raw sewage, chlorinated water & etc

OPERATING RANGE

Capacity : Up to 600 M/Hr

Head : Up to 180 Mtrs (590 Feet)

Capacity : Up to 2500 M/Hr

Head : Up to 80 Mtrs (262 Feet)

Temperature : Up to 140 C (284 F)

Casing Pressure: Up to 22 Kg / cm

Pump size ( Delivery bore) : 65 mm to 400 mm

Speed :Up to 1480 rpm

Direction of rotation : Clockwise from drive end

Frequently Asked Questions

Regular inspection of seals, impeller, and motor alignment is recommended. Ensure that the pump is not run dry and that fluid compatibility is always verified before use.

A chemical transfer pump is a specialized device designed to move chemicals safely and efficiently from one container to another, often used in industrial, laboratory, and processing applications.

Yes, when used correctly. They are designed with safety features like leak-proof seals and corrosion-resistant materials to minimize the risk of spills and exposure.

Yes, regular inspection, cleaning, and maintenance are essential to ensure reliable operation and extend the lifespan of the pump, especially when handling aggressive chemicals.

Vacuum pumps are widely used in industries such as pharmaceuticals, electronics, food processing, chemical manufacturing, and laboratories for processes like drying, filtration, distillation, and packaging.

Download Brochure

Download Brochure