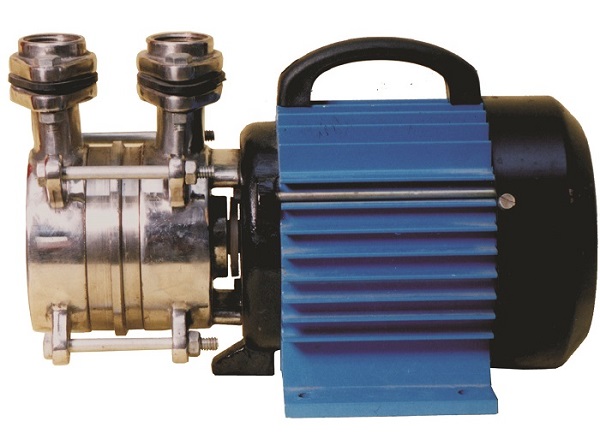

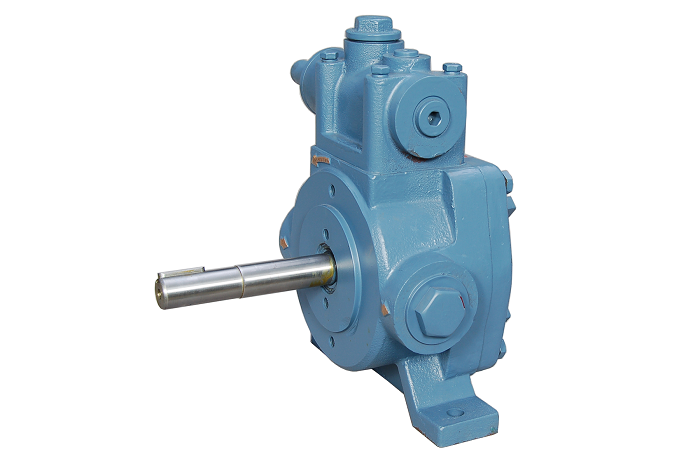

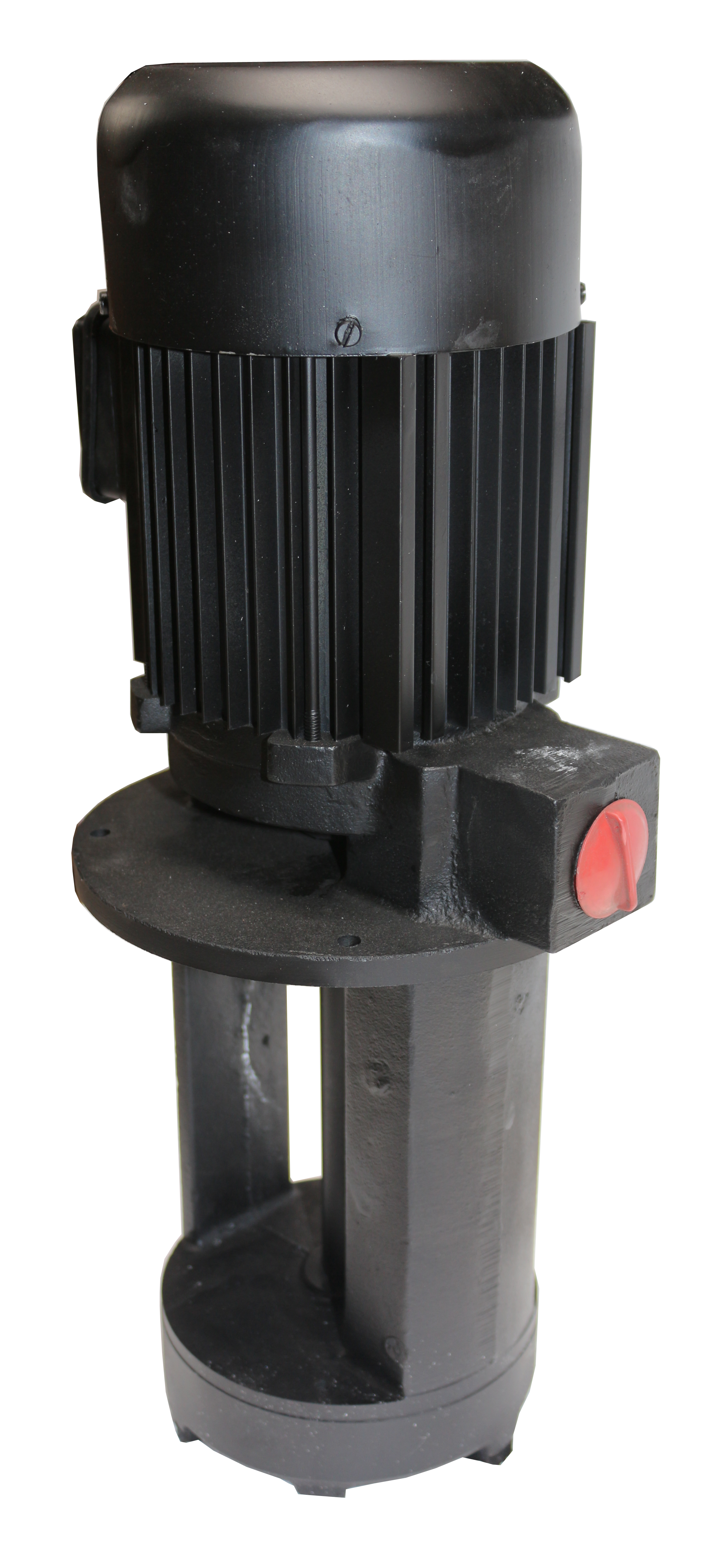

The Back Pull Out Pump is designed for easy maintenance and efficient performance, allowing the rotating assembly to be removed without disturbing the pipe connections. This minimizes downtime and simplifies service. Engineered for high reliability, it offers smooth operation, excellent hydraulic efficiency, and long service life. Its robust construction and precise design make it ideal for handling various industrial fluids while ensuring consistent flow and reduced operational costs.

Back Pull Out Pump Manufacturer

Are you searching for Back Pull Out Pump Manufacturer, Supplier, and Exporter from Ahmedabad, India than Creative Engineers is the perfect for you. We specialize in high-quality Back Pull Out Pumps designed for efficient performance and durability. Our pumps are ideal for industrial applications, offering easy maintenance and reliable operation. With advanced technology and precision engineering, we ensure top-notch quality at competitive prices. As a trusted name in the industry, we cater to domestic and international markets.

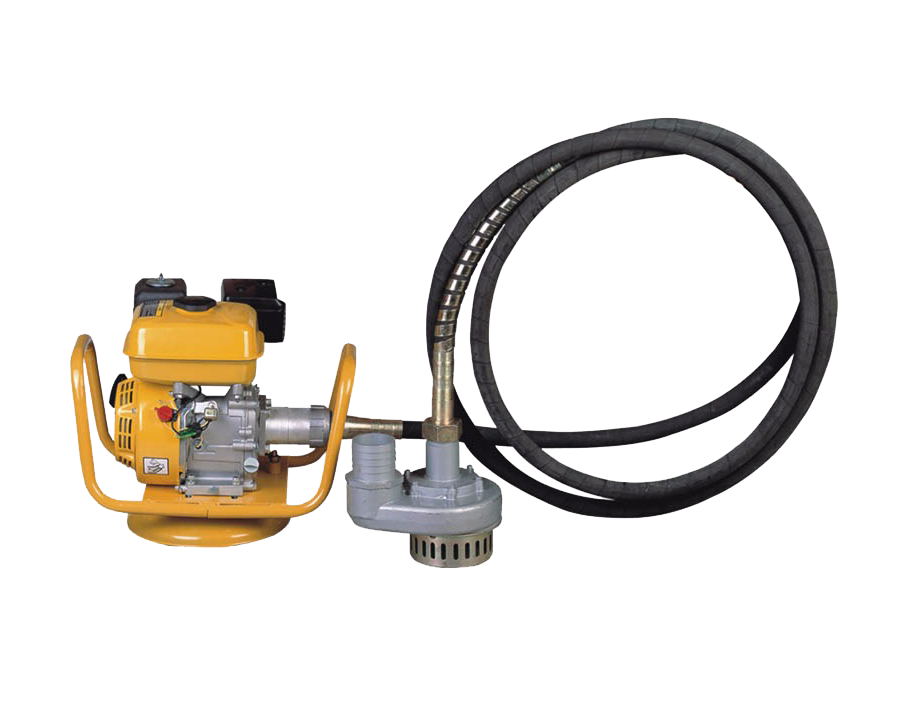

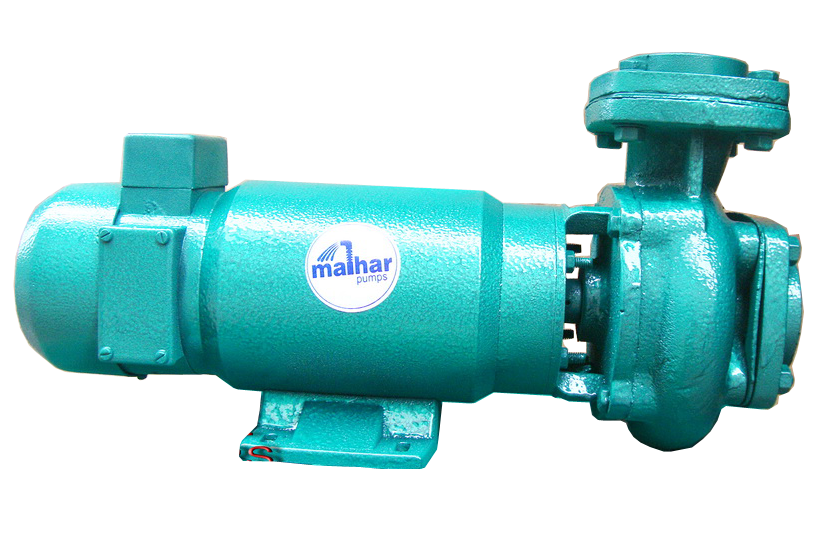

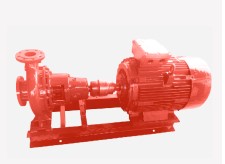

Back Pull Out Pump Application

- For pumping Clear / Turbid water / Chemicals & Volatile Liquids. Air conditional plants , power station , Mine Drainage ,

- Sprinkle systems fire fighting , Booster service , Oils Brine.

- STANDARD : AS PER DIN 24255/6 & ISO 2858

- OPERATING RANGE

- Delivery size up to 250 mm

- Capacity up to 990M3/hr

- Head up to 120 meters

- RPM 500 to 3600

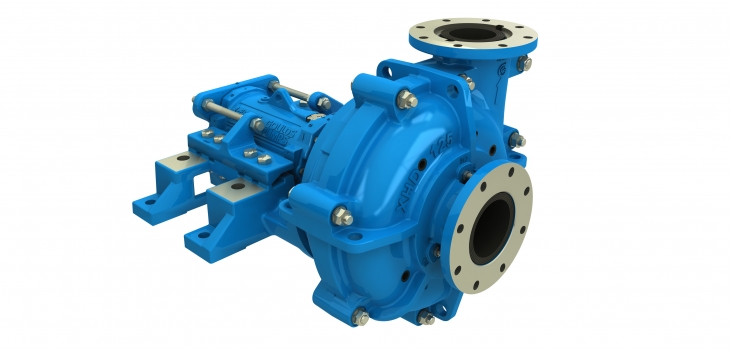

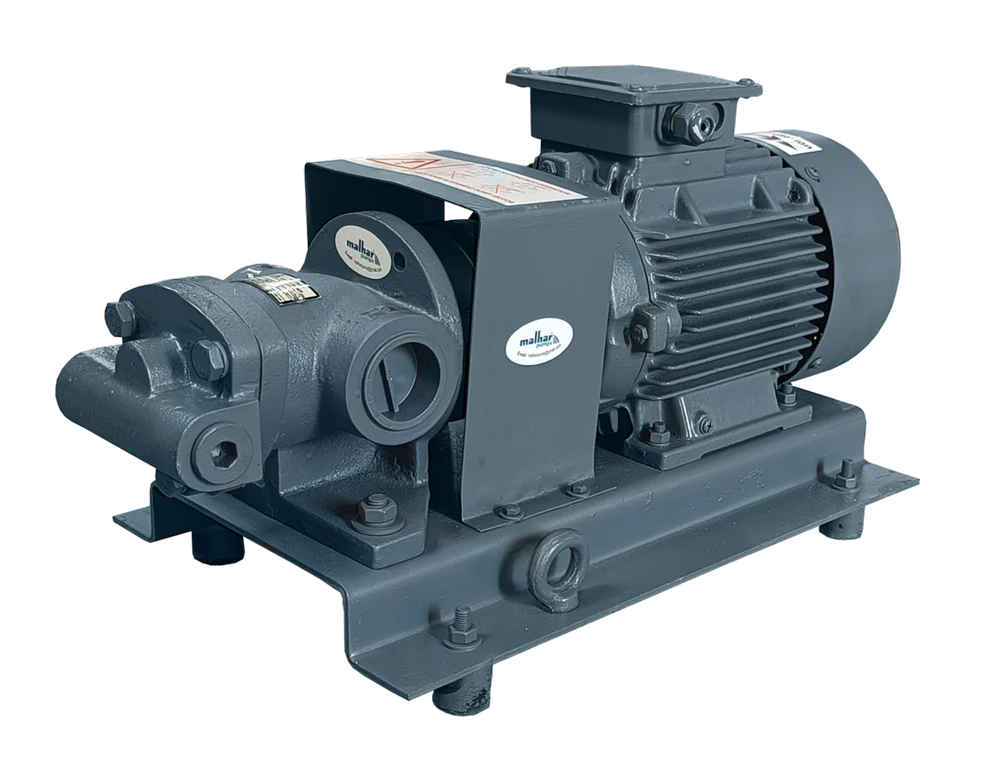

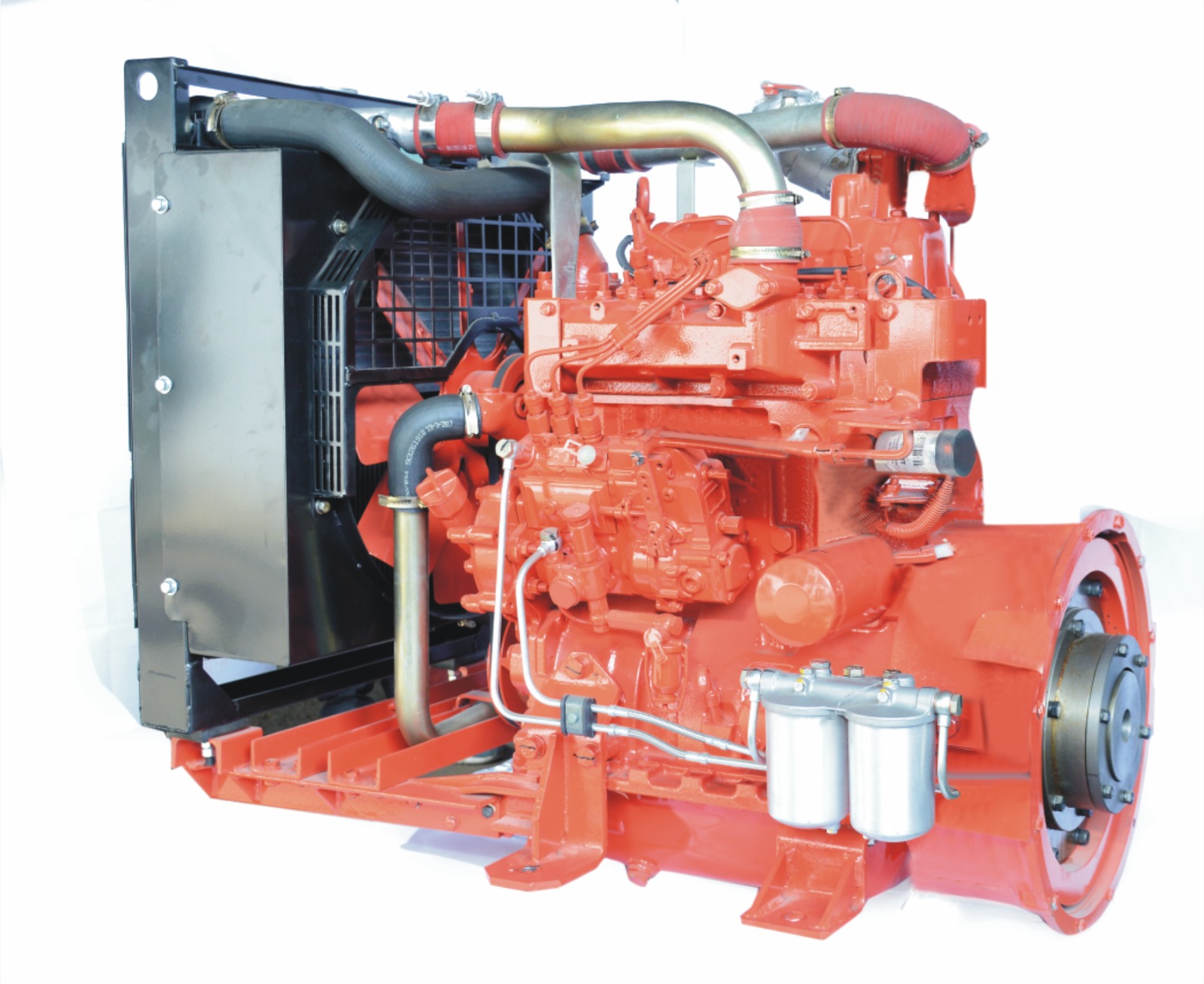

“ACH” SERIES BACK PULLOUT PUMPS (SLURRY APPLICATION)

- APPLICATION

- “ACH” Type pumps are used in Chemical & Petrochemicals Industry, Food Industry, Dyeing , Sugar Industry, Paper & Pulp Industry, Fertilizer Units & Etc.

- Handling of all types of Liquids , Acids , Alkalis , Dyes , Hydrocarbons ,Corrosive Slurries (Solids Up to 15 mm) , Green , Black Liquor , Pulp (Consistency up to 2%) & Etc.

- DESIGN

- “ACH” Type pumps are used in Chemical & Petrochemicals Industry, Food Industry, Dyeing , Sugar Industry, Paper & Pulp Industry, Fertilizer Units & Etc.

- Handling of all types of Liquids , Acids , Alkalis , Dyes , Hydrocarbons ,Corrosive Slurries (Solids Up to 15 mm) , Green , Black Liquor , Pulp (Consistency up to 2%) & Etc.

- OPERATING RANGE

- Capacity : Up to 600 M3/Hr

- Head : Up to 180 Mtrs (590 Feet) Temperature : Up to 200° C (392° F) Casing Pressure : Up to 24 Kg / cm2

- Pump size ( Delivery bore)

- : DN 25 mm to DN 200mm

- Speed : Up to 2900 rpm

- Direction of rotation: Clockwise from drive end

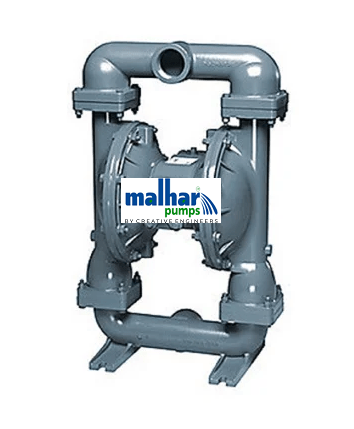

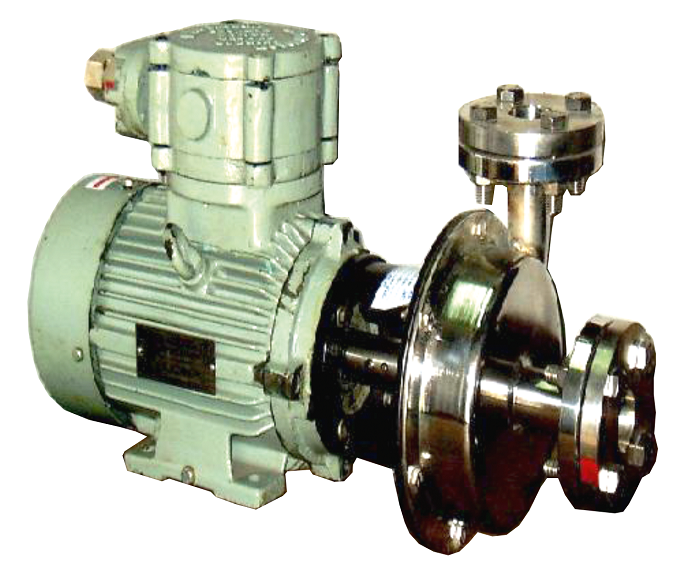

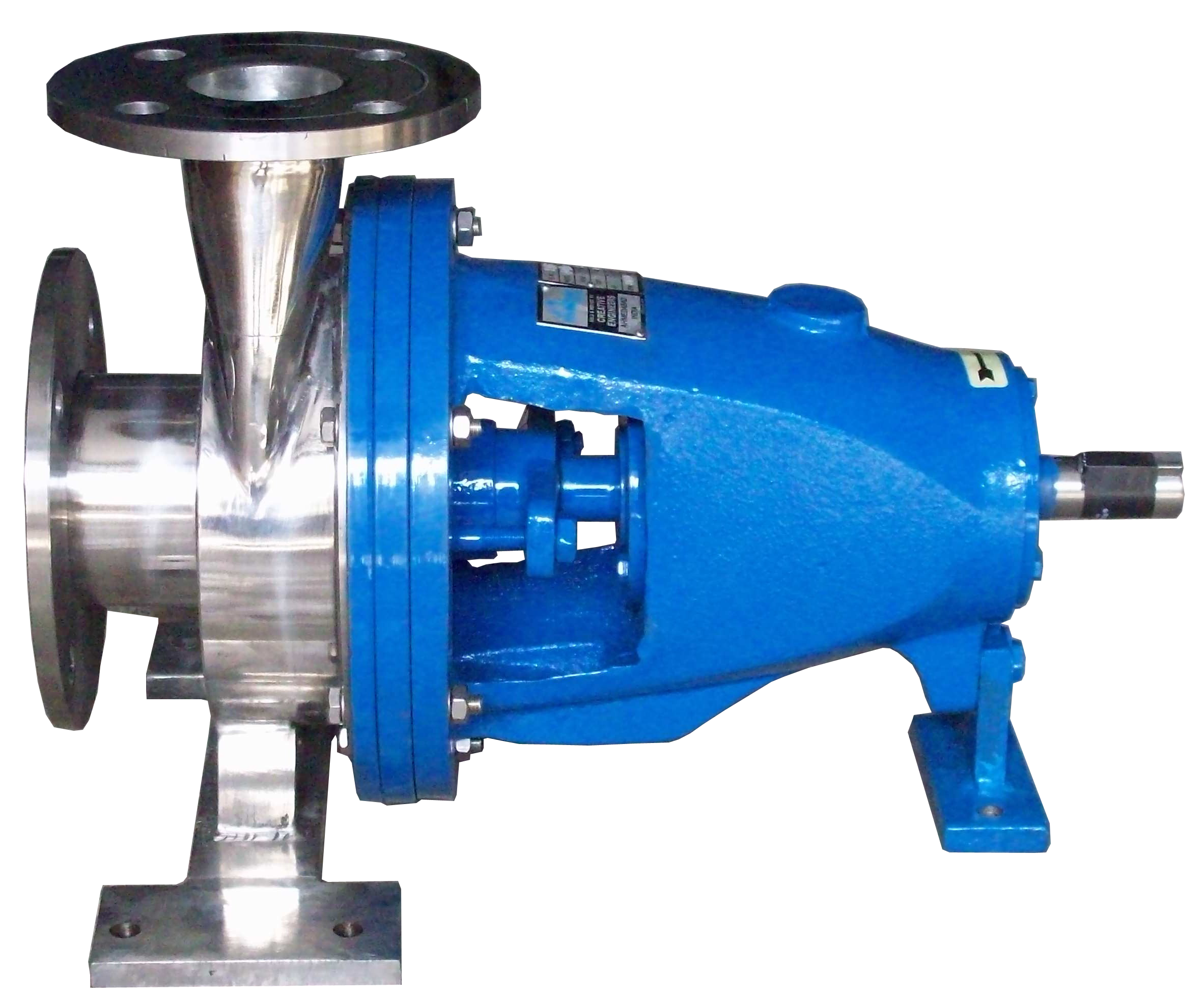

“PS” SERIES BACK PULLOUT PUMPS (PULP APPLICATION)

- “PS” Type pumps are used in paper & pulp industry, food industry, sugar industry, efficient plants, sea water desalination plants, chemical & petrochemicals industry, power stations and absorption plants in environmental engineering & etc.

- Handling of pulp & paper stocks up to 5% consistency heavily contaminated liquids, raw sewage, chlorinated water & etc

- OPERATING RANGE

- Capacity : Up to 600 M3/Hr

- Head : Up to 180 Mtrs (590 Feet)

- Capacity : Up to 2500 M3/Hr

- Head : Up to 80 Mtrs (262 Feet) Temperature : Up to 140 C (284 F) Casing Pressure : Up to 22 Kg / cm2

- Pump size ( Delivery bore): 65 mm to 400 mm

- Speed : Up to 1480 rpm

- Direction of rotation: Clockwise from drive end

Download Brochure

Download Brochure