Centrifugal Pumps

How does centrifugal pump work?

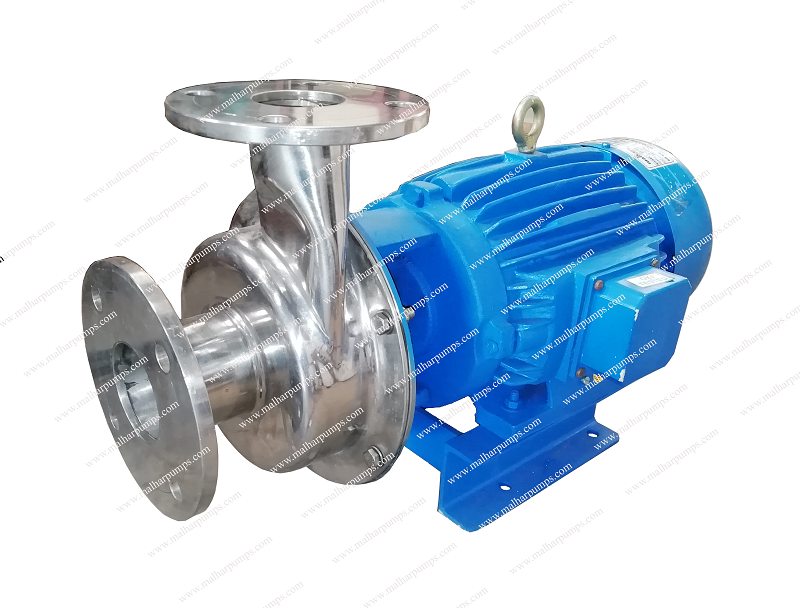

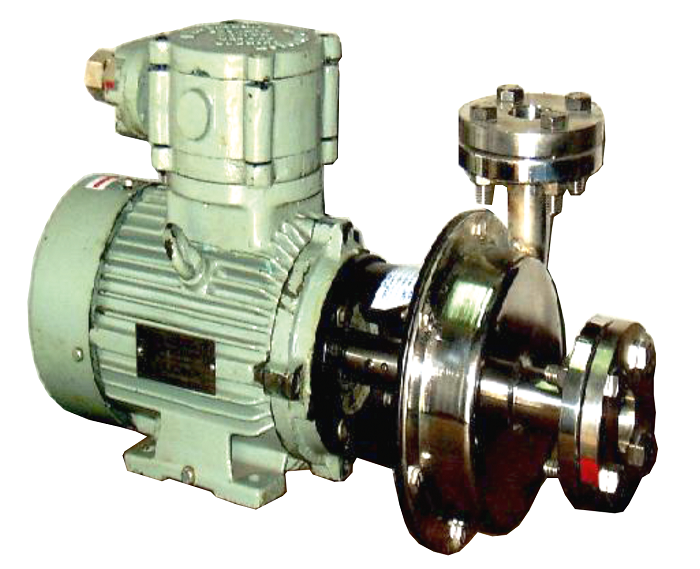

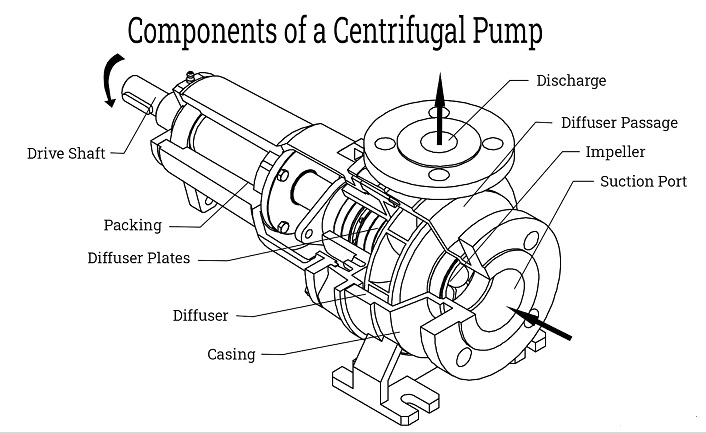

The most important part of a centrifugal pump is the impeller. It is made up of several bent vanes. Typically, these are positioned in between two discs. It is preferable to use an open or semi-open impeller supported by a single disk for fluids containing entrained materials. Figure 1 Fluid travels along the circumference between the vanes as it leaves the impeller at the eye, which serves as its axis.

What are the main features of a centrifugal pump?

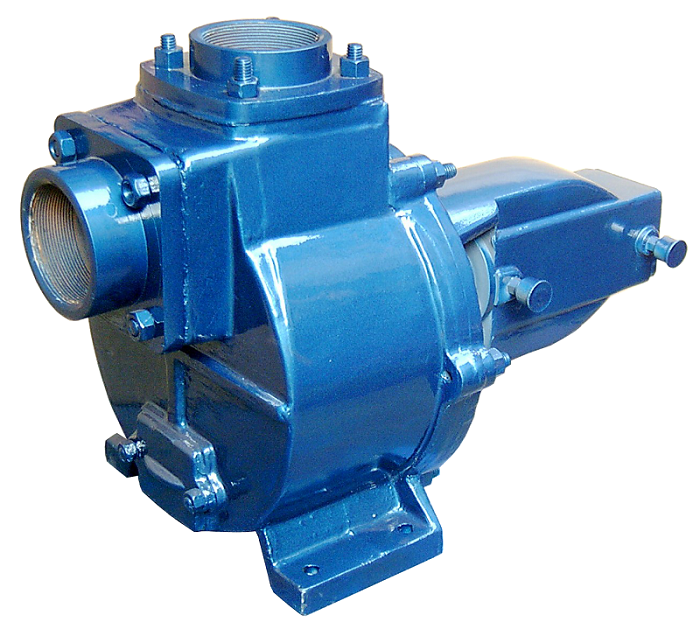

Centrifugal pumps and displacement pumps are the two primary types of pumps. Centrifugal pumps are designed to pump low viscosity liquids down to 0.1 cP and are typically specified for higher flow rates than reciprocating pumps. Centrifugal pumps account for 90% of the pumps in certain chemical plants. Nevertheless, positive displacement pumps remain the favored option for numerous applications.

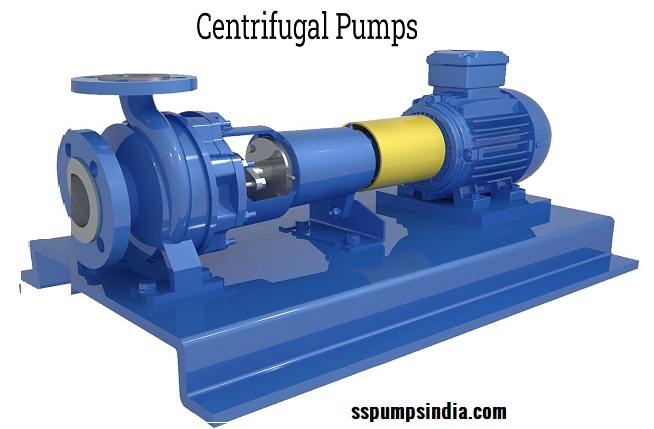

What is a Centrifugal Pump?

The mechanical mechanism of a centrifugal pump transfers rotational energy from one or more driven rotors, also known as impellers, to move fluid. Through the tips of the impeller's vanes, the fluid enters the fast rotating impeller along its axis and is released by centrifugal force along its circle. The fluid is directed toward the pump output by the impeller's movement, which also raises the fluid's pressure and velocity. The fluid from the pump input is compressed by the pump casing, which then directs it to the impeller, slows it down, and regulates it before it discharges.

A centrifugal pump is a mechanical apparatus that transfers rotational energy from one or more impellers, or powered rotors, to move a fluid. Fluid enters the quickly spinning impeller along its axis and exits via the vane tips of the impeller along its circle due to centrifugal pumps.

Summary

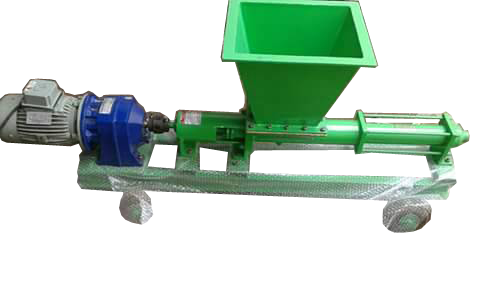

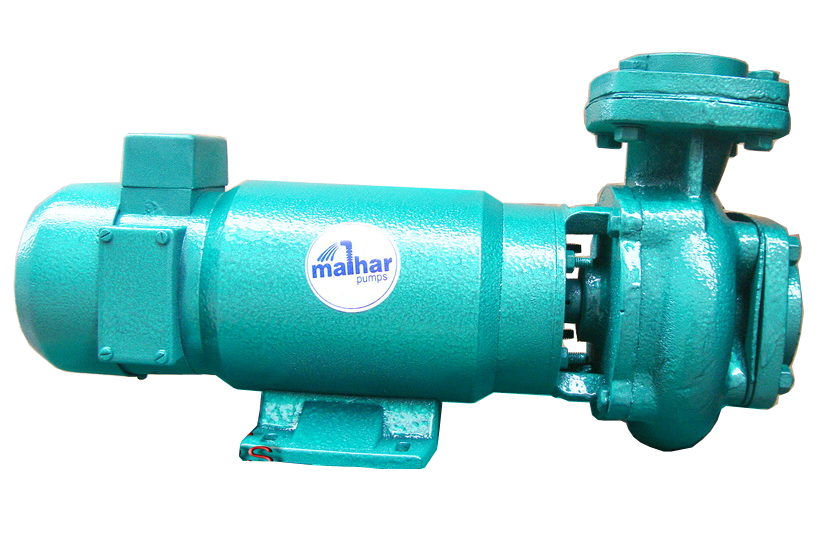

For the majority of low pressure, high capacity pumping applications involving low viscosity fluids like water, solvents, chemicals, and light oils, centrifugal pump designs provide straightforward, reasonably priced solutions. Common uses include irrigation, petrochemical plant chemical transfer, and water supply and circulation. Applications requiring precise dosing, complicated feeds like emulsions, edibles, or biological fluids, and extremely viscous fluids like thick oils and slurries—especially at high pressures—are better served by positive centrifugal pumps.