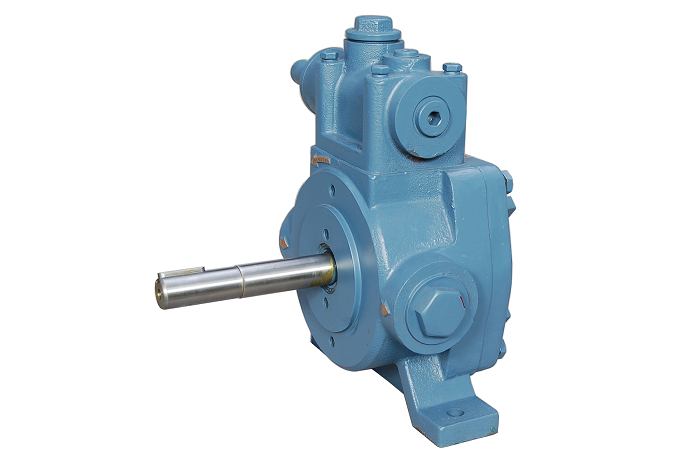

Rotary Gear Pump

- Home

- Rotary Gear Pump

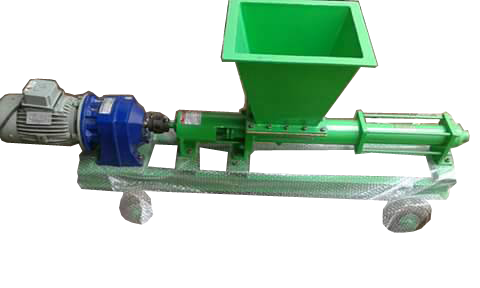

Rotary Gear Pump Manufacturer

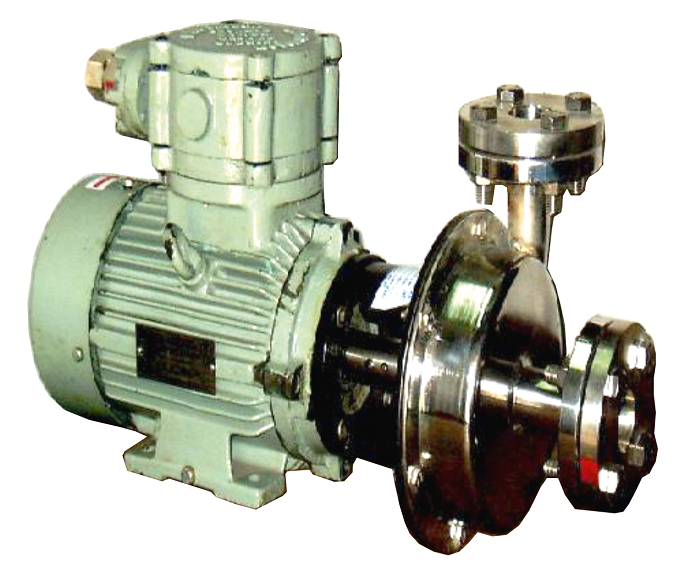

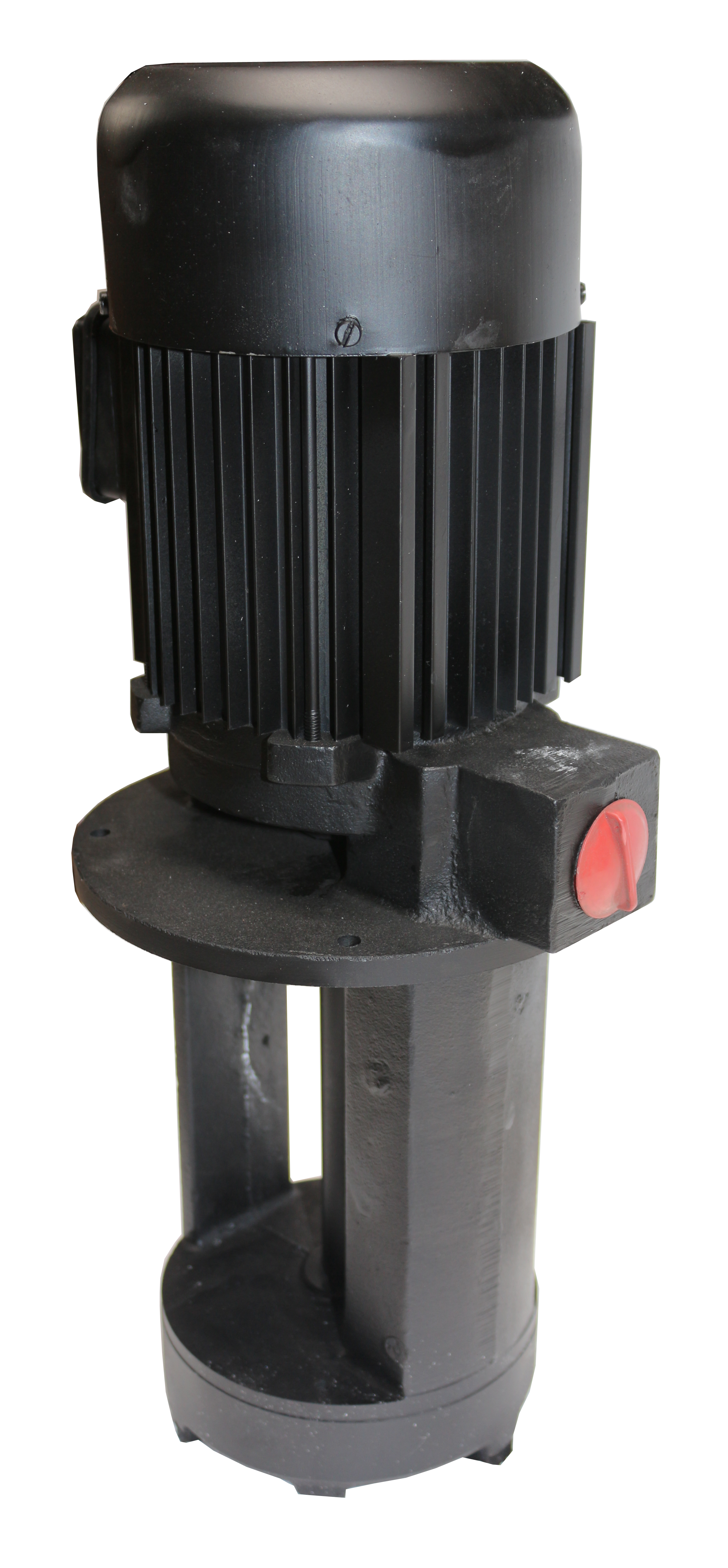

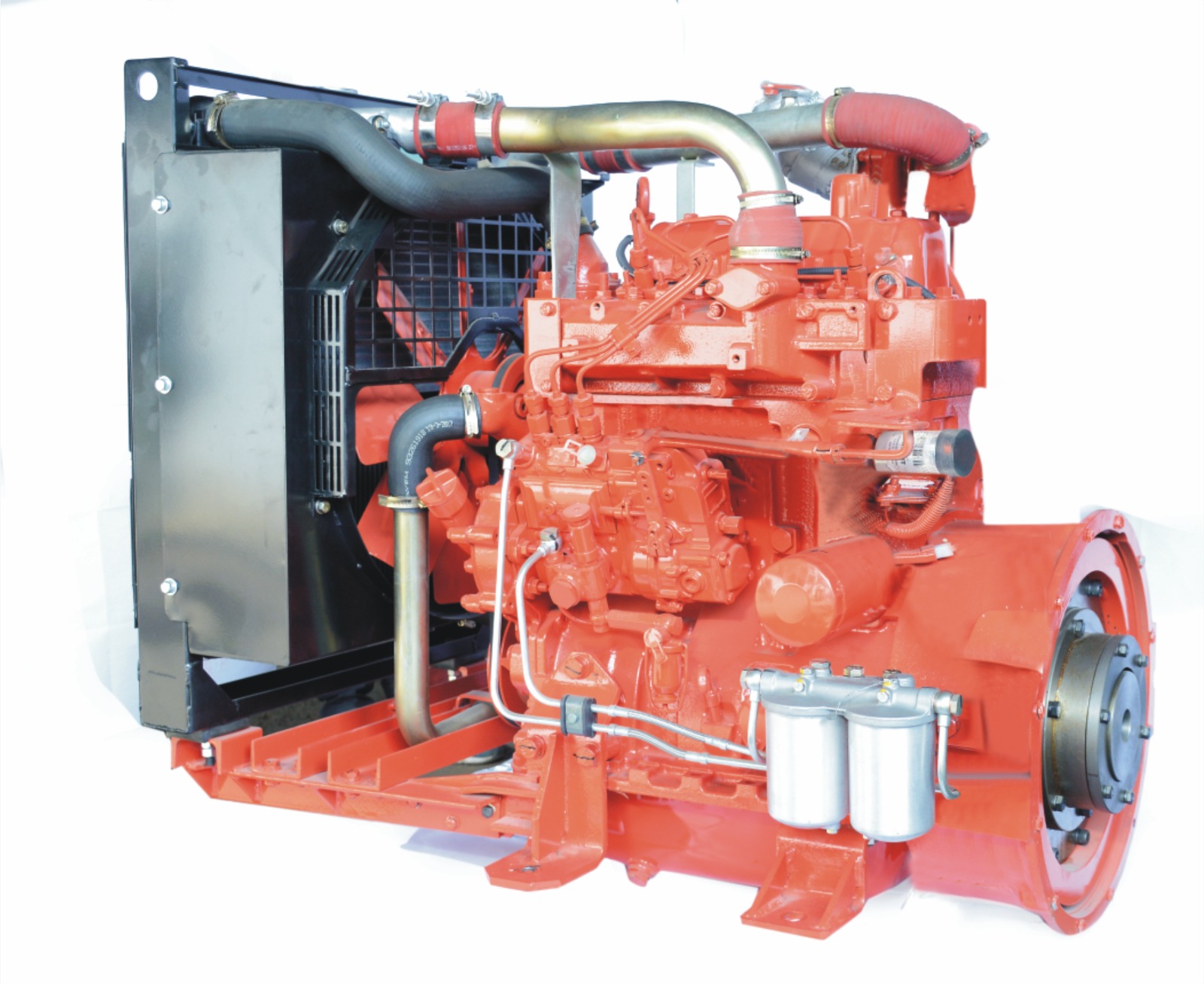

We are a leading Rotary Gear Pump Manufacturer in India, offering high-performance pumps for efficient and reliable fluid handling. Our rotary gear pumps are precision-engineered to deliver smooth, consistent flow with minimal noise and low maintenance. Featuring a compact design and robust construction, they are ideal for demanding industrial applications. Backed by advanced manufacturing technology and strict quality control, our pumps ensure long service life, enhanced productivity, and dependable performance across global markets.

A Rotary Gear Pump is a reliable positive displacement pump designed for the smooth, controlled, and efficient transfer of fluids across industrial applications. It operates using two or more intermeshing gears enclosed within a precision-engineered casing. As the gears rotate, fluid is drawn into the pump on the suction side, carried between the gear teeth and casing, and then discharged on the outlet side with consistent flow and minimal pulsation.

Known for its compact design, high efficiency, and excellent pressure-handling capability, gear pumps ensure precise flow control with minimal leakage. They are ideal for pumping oils, fuels, chemicals, resins, lubricants, and viscous liquids. Due to their durable construction, low maintenance requirements, and dependable performance, these pumps are widely used in industries such as chemical processing, pharmaceuticals, food & beverage, petrochemicals, hydraulic systems, and lubrication units. Rotary gear pumps deliver long service life and consistent operation, making them a preferred choice for demanding fluid transfer applications.

Leading Rotary Gear Pump Manufacturer for Industrial Fluid Handling

Creative Engineers is one of the leading Rotary Gear Pump Manufacturers, Suppliers, and Exporters in India, offering high-performance rotary gear pumps designed for efficient fluid transfer across industries, including oil, chemical, and food processing. Engineered with precision, our pumps are known for their durability and smooth operation. Committed to quality and innovation, we deliver customised pumping solutions tailored to meet diverse industrial requirements.

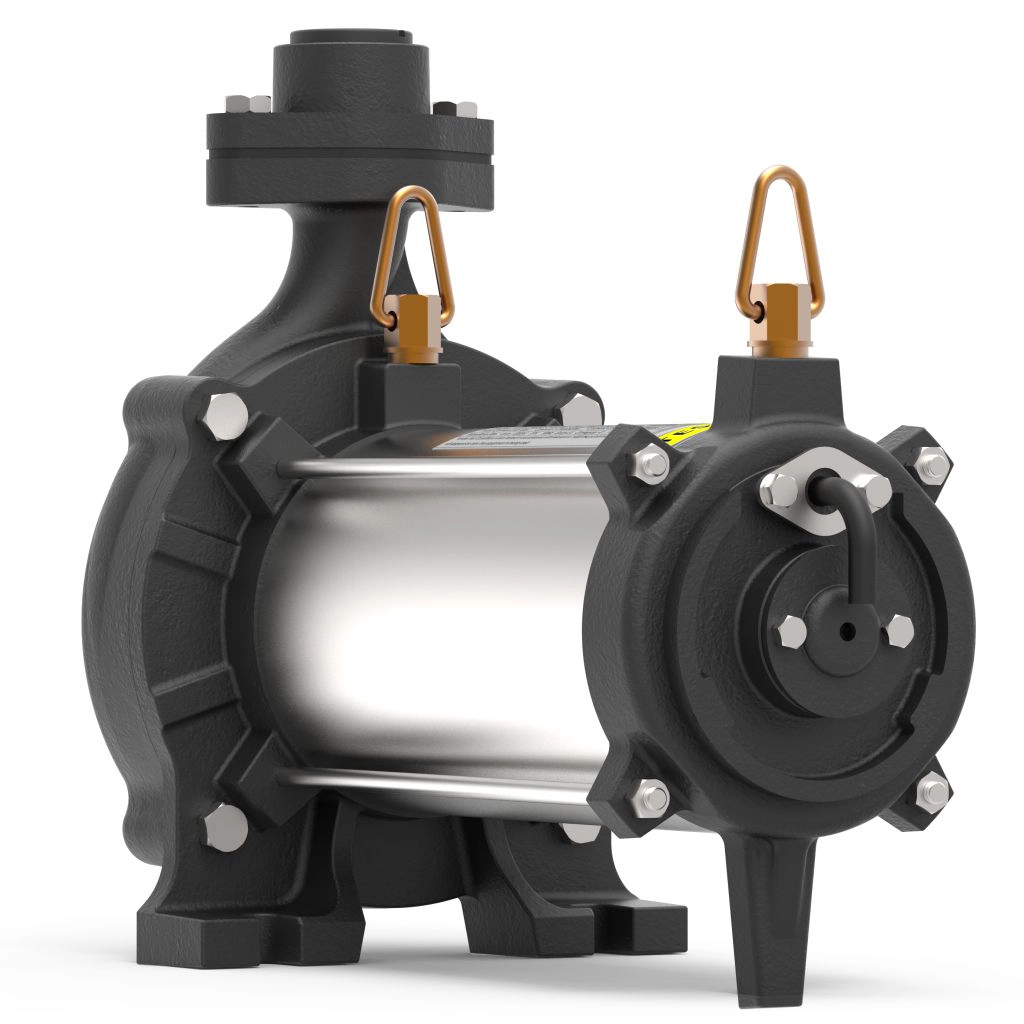

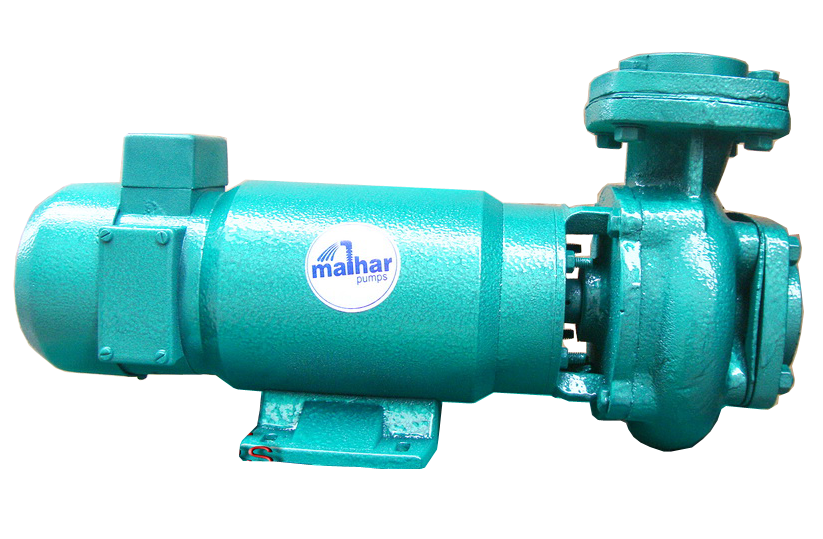

Two Main Types of Rotary Gear Pumps

1. External gear pump: External gear pumps consist of two external gears that mesh together and rotate in opposite directions. The fluid is trapped between the gears and the casing, and then pushed out of the pump.

2. Internal gear pumps: Internal gear pumps, on the other hand, have an internal gear that rotates within a larger external gear. The fluid is drawn into the pump through the inlet port and then forced out through the outlet port.

Leading Gear Pump Manufacturer

With over 26 years of industry experience, Creative Engineers is an ISO 9001:2008 certified manufacturer, supplier, and exporter of gear pumps in India. Our premium gear pump range in India is designed for precision, durability, and performance across industrial sectors.

Frequently Asked Questions

A rotary gear pump is a type of positive displacement pump that uses meshing gears to pump fluids by displacement, commonly used for viscous liquids.

It operates by trapping fluid between the teeth of two or more gears and the pump casing, then moving it from the inlet to the outlet with consistent flow.

Yes, they are capable of handling moderate to high pressure and are ideal for applications that require precise and steady fluid delivery.

Regular maintenance involves checking for wear in gears and seals, ensuring proper lubrication, and inspecting for any signs of leakage or reduced performance.