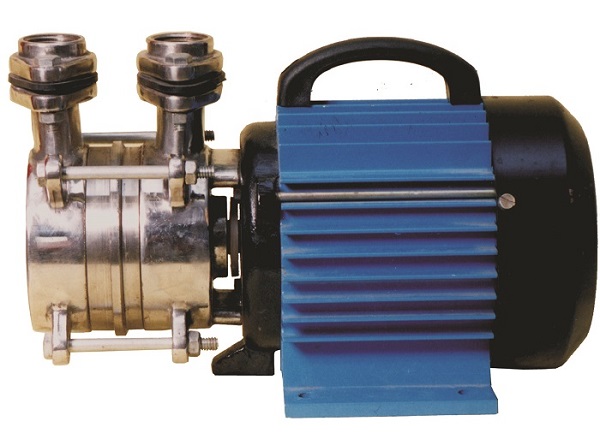

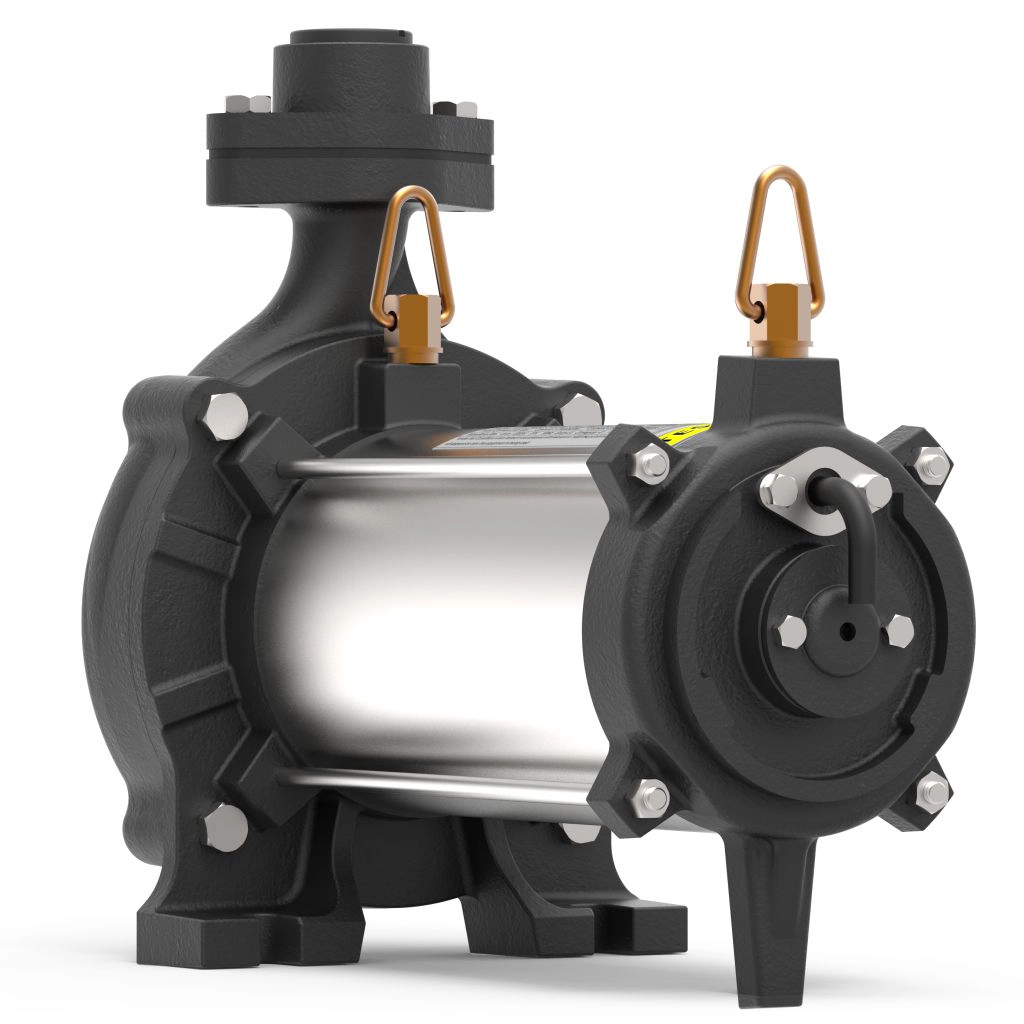

CFS Series Stainless Steel Centrifugal Pump Manufacturer

Are you looking for CFS Series Stainless Steel Centrifugal Pumps manufacturer, supplier, and exporter in Ahmedabad, India? Creative Engineers is your trusted choice for high-quality, durable, and efficient stainless steel centrifugal pumps. Our CFS Series pumps are designed for superior performance, corrosion resistance, and long-lasting reliability, making them ideal for industrial applications. As a leading manufacturer and exporter, we ensure top-notch quality and competitive pricing. Contact Creative Engineers today to get the best CFS Series Stainless Steel Centrifugal Pumps in India.

APPLICATION

- Milk, Cream, Butter Milk, Condensed Milk

- Fruit juice, Beer, Wine, Sugar Syrup

- Vitamin Solutions, Sugar & Confectionery.

- RO Water, DM Water, Pure Water. Water for Injection (WFI)

- Vegetable Oil, Mineral Oil, Lub Oil etc.

- Pharmaceutical Formulations, Syrup etc.

- Alkaline Solution / Alcoholic Drinks.

- Acids, Fine Chemicals

- Bottling Plants, Soft Drinks & Distillery

- Food Processing / Liquid Food Stuffs

- Colour dyes and Pigments / Paints

- Descaling Applications, Paper & Cement Industries

- Water Treatment Plants

- Detergent, Soaps, Paste & Shampoo

- Textile Sizing, Dyeing & Finishing Systems

- Natural Cellulose Fiber / Synthetic Fiber System

- Hot & Cold Water Pumping

FEATURES

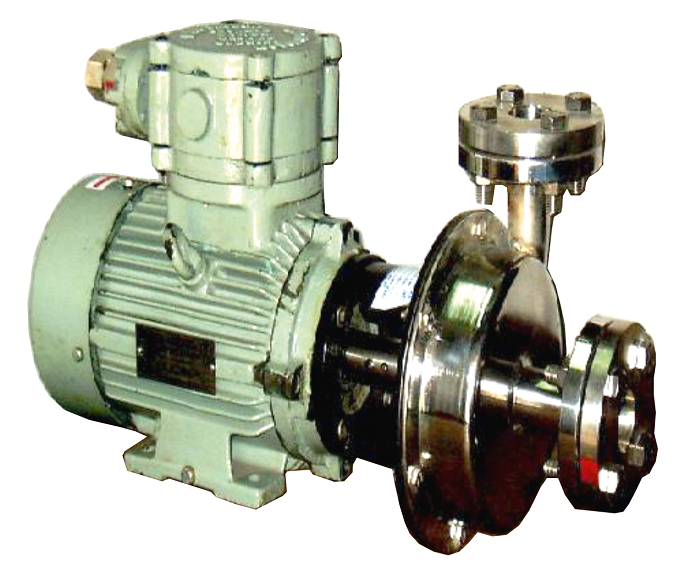

- As all pumps are made from rolled stainless steel, mechanical properties are far superior than cast material.

- Pore free, non-pitting and non-adhering smoother surface, so lesser friction losses, and lesser service corrosion.

- Super finished surface also ensures no ingress or emission of germs or impurities during pumping or idling which is a basic requirement of sterile / hygienic application.

- Pump can handle liquids having viscosities up to 1500 centipoises.

- Pumps are highly energy efficient and requires lesser NPSH to function without cavitation.

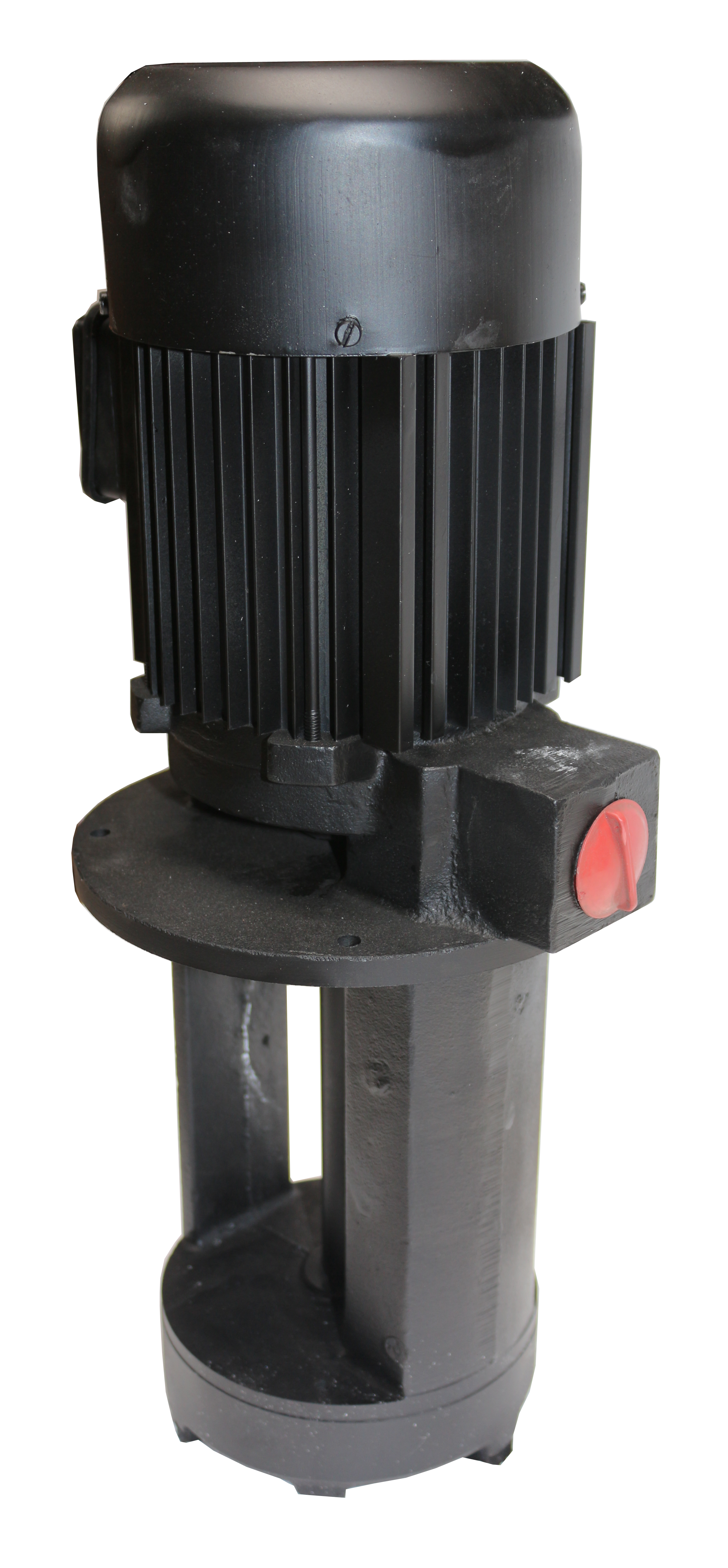

- The pumps can work under a vacuum of 720 mm of Hg, suitable for vacuum evaporators.

- Pumps are available with cosed/semi open impellers.

- The best elastomers are used in the pumps to provide optimum resistance for high temperatures and chemicals.

- Minimum working / rotating parts.

- Safe and quiet operation levels.

- Gentle product handling with lower maintenance and downtime cost.

- Dynamic combinations of seal faces as per customer's requirement (single seal / double seal, seal external cooling ).

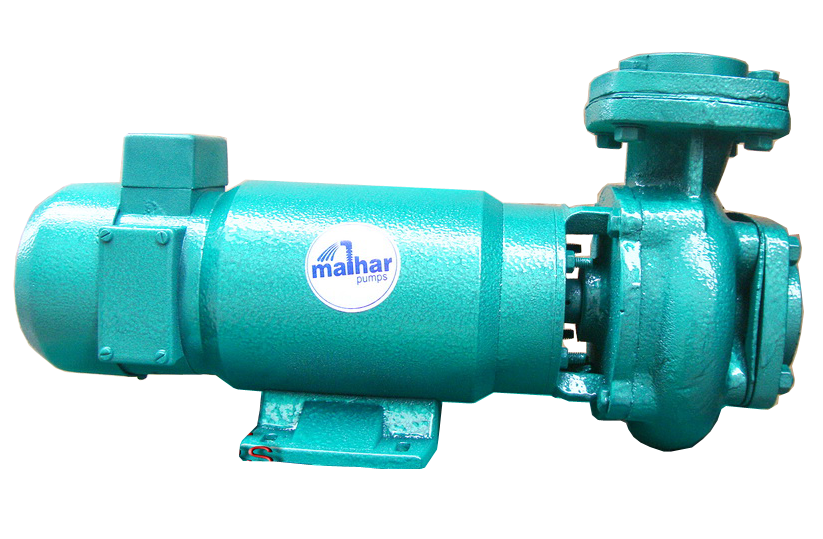

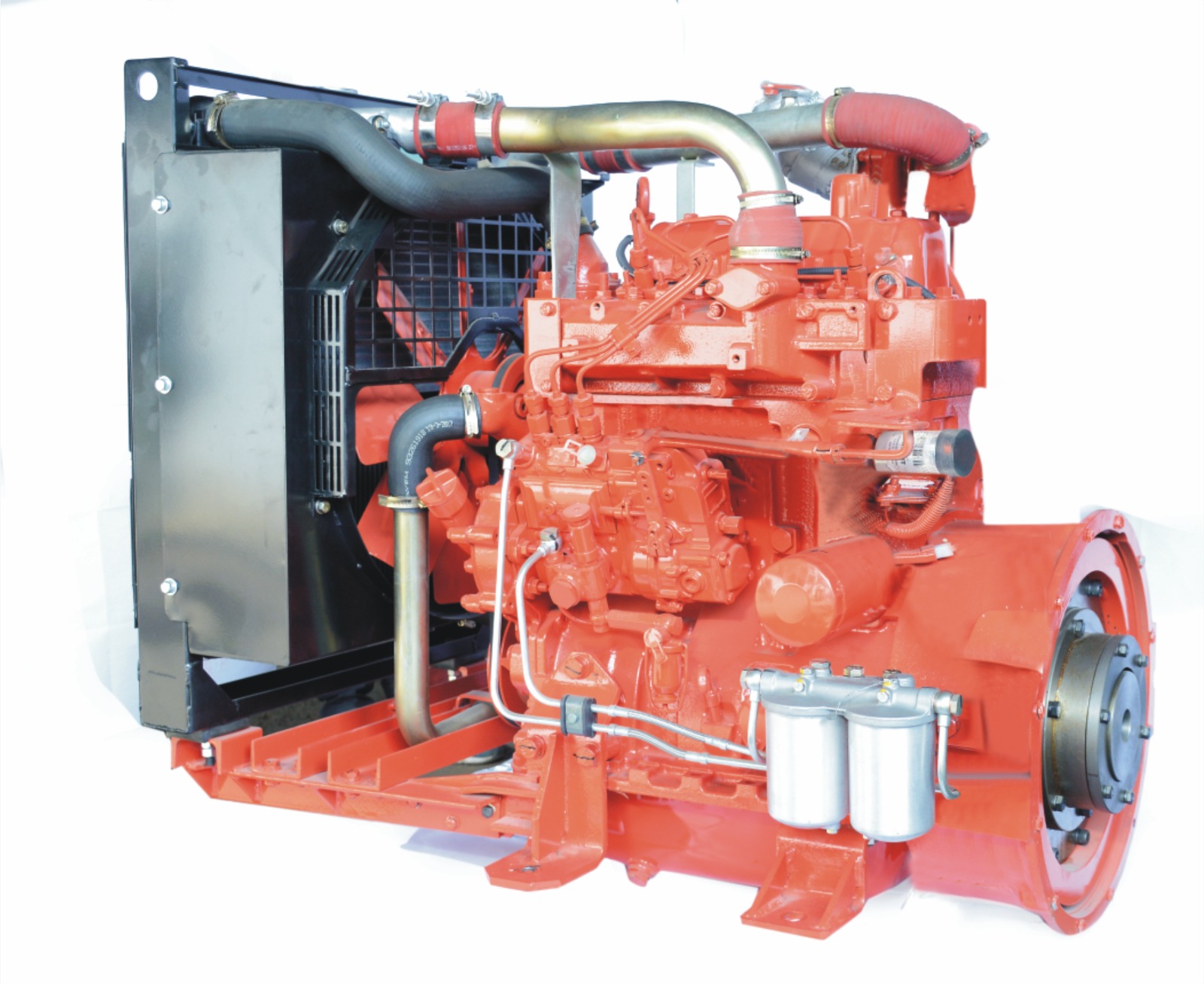

- Suitable for standard motor or flange type or foot cum flange type motor or engine

- Monoblock or bare pumps or with trolley.

Download Brochure

Download Brochure