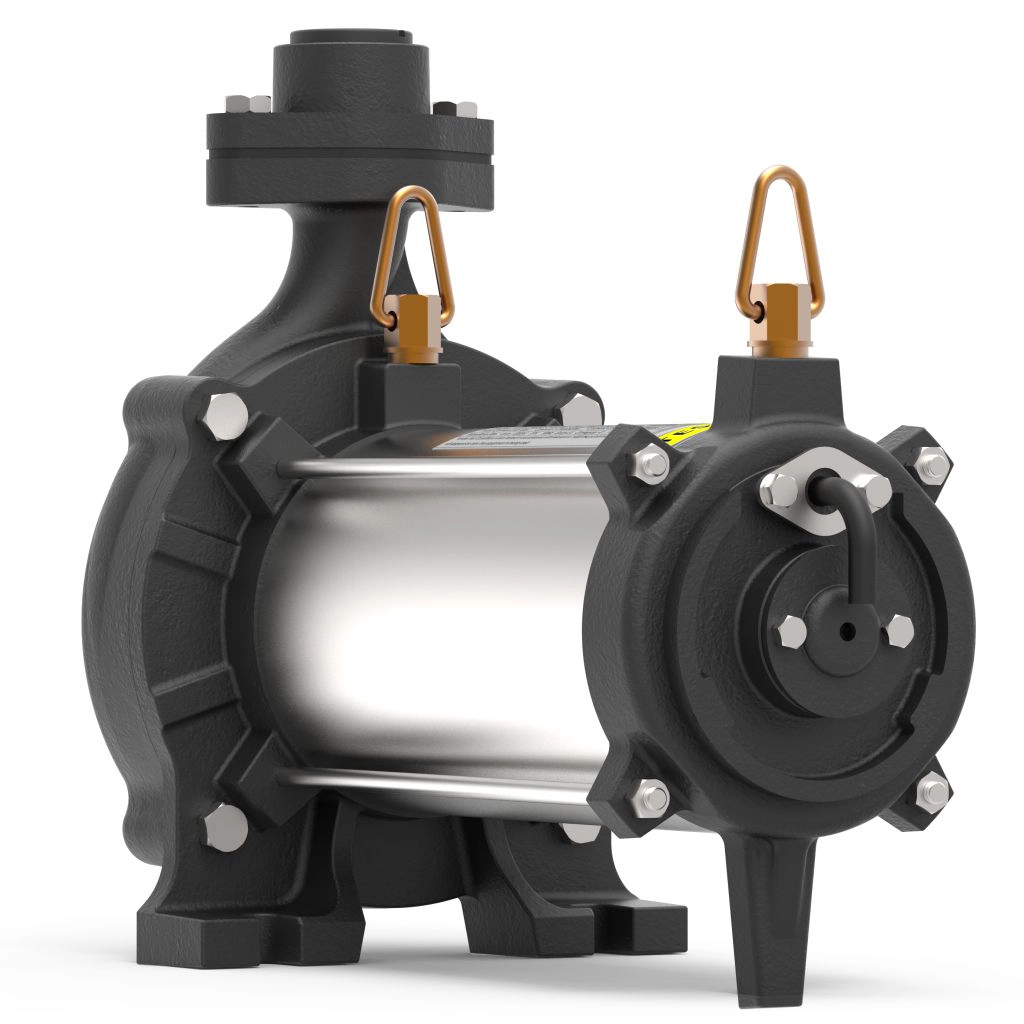

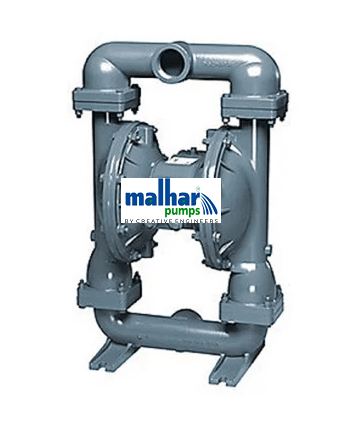

An Air Operated Double Diaphragm Pump is a highly versatile and efficient pumping solution suitable for handling a wide range of fluids, including corrosive, abrasive, and viscous materials. Designed for durability and reliability, it operates without electricity, making it safe for hazardous environments. Its self-priming capability allows easy installation and flexibility in various applications. With low maintenance requirements and a leak-proof design, it ensures consistent performance and reduced downtime. The pump delivers exceptional efficiency and fluid control, making it use for industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment.

Air Operated Double Diaphragm Pump Manufacturer

Are you searching for Air Operated Double Diaphragm Pump Manufacturer in India? Creative Engineers is the perfect choice for you. We specialize in high-quality AODD pumps, designed for efficient fluid transfer using compressed air as the power source. Our pumps ensure reliable performance, seamlessly handling a wide range of fluids—from clean, low-viscosity liquids to medium-viscosity materials. Engineered to transfer large particles without damage, they offer dry-run capability, making them suitable for diverse industrial applications.

Air Operated Double Diaphragm Pump Applications :-

- To Handle Viscous chemicals , Slurries.

- To transfer Explosive liquids , solvents , Acids.

- Pharmaceutical liquids creams and compounds.

- Semi solid foods , flavours , drinks , wine , beer , alcohols.

- Waste water , sewage effluents , coal and lime slurry.

- Hydrocarbons , petrol diesel , lubrication oil , vegetable oil.

- Paints Emulsions , pigments , thinners , resins.

- Ceramics , slip , gazes , clays.

Advantages of AODD Pump :-

- No Seal , No Leakage,

- Self priming , No need of foot valve,

- Variable flow with same pump.

- Can be submerge.

- Less stock of spare to be maintain.

- No Skill person is needed to operation and repair pump.

- Light weight , handy in use.

- No Rotation , no Wear & Tear hence low maintenance , No Charging.

Pump can run dry. - Stop Automatic on closing of discharge valve.

- Can handle 2 to 10 mm size solid particles.

- Also can be used upto accuracy 3 to 5%

No Motor , No fire. - In short very simple and versatile pump.

Operation Principle :-

- Dry air is given as input to air valve. Air will push both diaphragm alternatively.

- Four ball valves will act as NRV for suction and delivery.

- As per liquid compatibility MOC of diaphragm, Valve and wetted part selected.

Range :-

Sr No |

Model | Material of Casing | Air Press in Bar | Max Solid Size in MM | Suc*Dis BSP | Flow Range in LPM |

1 | AODD 15 | PP , SS , PVDF , AL | 7 | 2.5 | 0.5” | 0-25 |

2 | AODD 25 | PP , SS , AL , PVDF | 7 | 3.4 | 1” | 0-59 |

3 | AODD 40 | PP , SS , AL | 7 | 5 | 1.5” | 0-137 |

4 | AODD 50 | PP , SS , AL | 7 | 6.5 | 2” | 0-295 |

5 | AODD 80 | Aluminium | 7 | 10 | 3” | 0-440 |

Download Brochure

Download Brochure